Explore the vital role of thermal potting compound in electric motors for effective heat management, electrical insulation, and mechanical stability. Learn about material selection and the application process.

Thermal Potting Compound in Electric Motors: Optimizing Heat Dissipation & Reliability

Applications of Thermal Potting Compound Inside Electric Motors

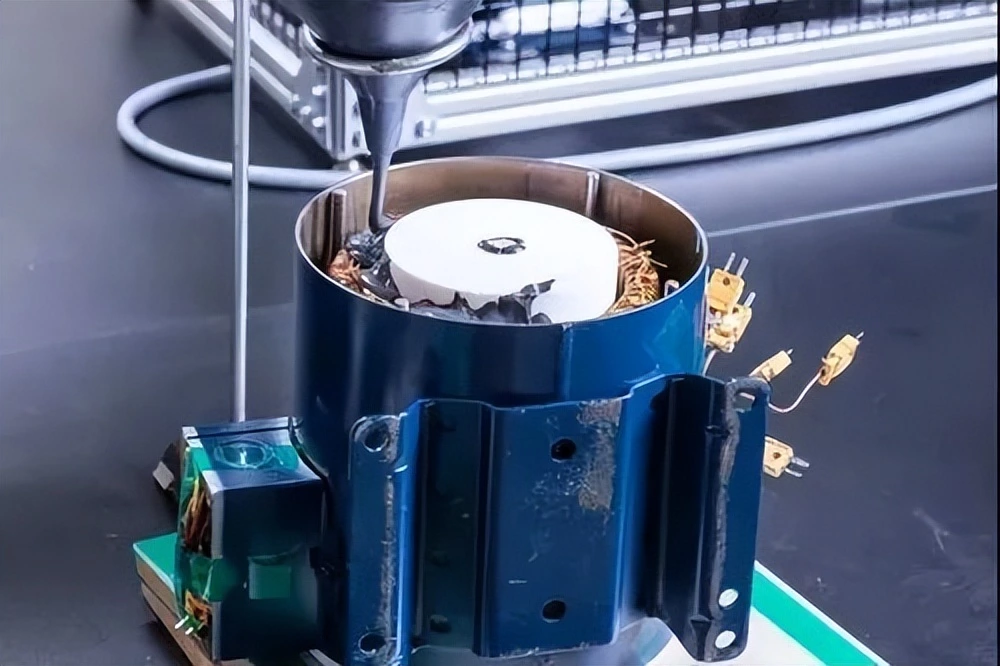

The application of thermal potting compound within electric motors is primarily focused on optimizing heat dissipation and enhancing reliability, while also protecting them from environmental factors. Here are the key aspects of thermal potting compound application inside electric motors:

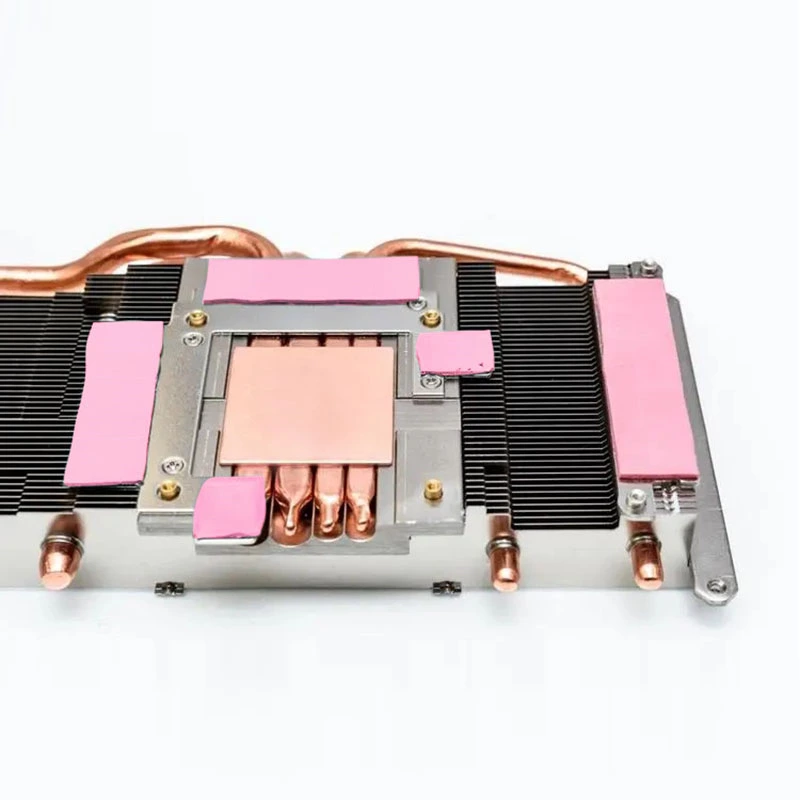

Enhanced Thermal Management: Electric motors generate heat during operation, which can impact their efficiency and lifespan. Thermal potting compounds, with their specific thermal conductivity properties, facilitate the efficient transfer of this heat away from the motor's internal components to the external environment, ensuring optimal operating temperatures.

Reliable Electrical Insulation: While primarily focused on thermal management, thermal potting compounds also provide good electrical insulation, preventing current leakage, reducing the risk of short circuits, and protecting the motor from electrical failures.

Providing Mechanical Protection and Vibration Resistance: By filling internal spaces and securing components, thermal potting compounds offer mechanical protection against shocks and vibrations, contributing to the motor's overall stability and durability.

Moisture and Environmental Sealing: Thermal potting compounds act as a barrier against moisture, humidity, and other environmental contaminants, preventing corrosion and damage to electrical parts, thereby extending the motor's operational life.

Dust and Contaminant Protection: Encapsulating motor components with thermal potting compound helps prevent the ingress of dust, dirt, and other particles that can hinder performance and require maintenance.

Contributing to Noise Reduction: The application of thermal potting compound can also help dampen and reduce noise generated by the motor during operation, which is beneficial in noise-sensitive applications.

Enabling Operation in Extreme Environments: Certain thermal potting compounds are formulated to withstand extreme temperatures and chemical exposure, ensuring the reliable operation of electric motors in demanding environments.

When selecting a thermal potting compound, it is crucial to consider the specific thermal management needs, application environment, and performance requirements of the electric motor. Choosing the appropriate type of thermal potting compound (e.g., based on thermal conductivity, viscosity, and other properties) is essential for achieving optimal motor performance and long-term reliability.

The Application Process of Thermal Potting Compound for Motors

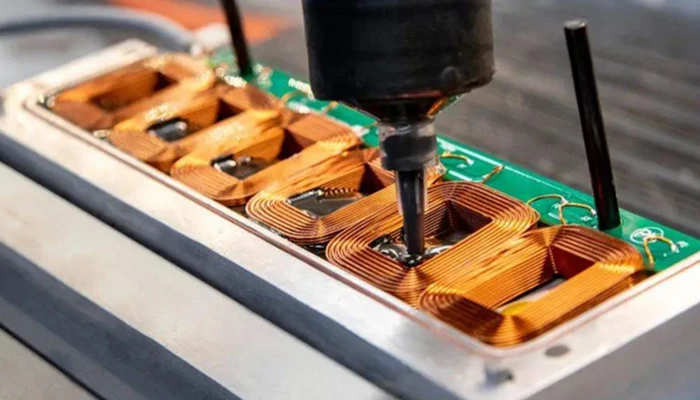

The application process of thermal potting compound is crucial for ensuring the effective heat dissipation and long-term reliability of electric motors. Here are the fundamental steps and considerations:

1. Cleaning and Preparing Motor Components for Potting: Ensure all surfaces of the motor components and the potting container are clean, dry, and free from any contaminants that could affect adhesion or thermal transfer.

2. Choosing the Right Thermal Potting Compound: Select a thermal potting compound with appropriate thermal conductivity, viscosity, curing characteristics, and other properties based on the motor's design and operating conditions.

3. Mixing Thermal Potting Compound Components Correctly: For two-part thermal potting compounds, accurately mix the resin and hardener according to the manufacturer's instructions, ensuring a homogeneous mixture without entrapping excessive air.

4. Degassing Thermal Potting Compound to Eliminate Bubbles: Remove any air bubbles introduced during mixing by using a vacuum chamber or other degassing methods. Air bubbles can impede thermal transfer and reduce the effectiveness of the potting.

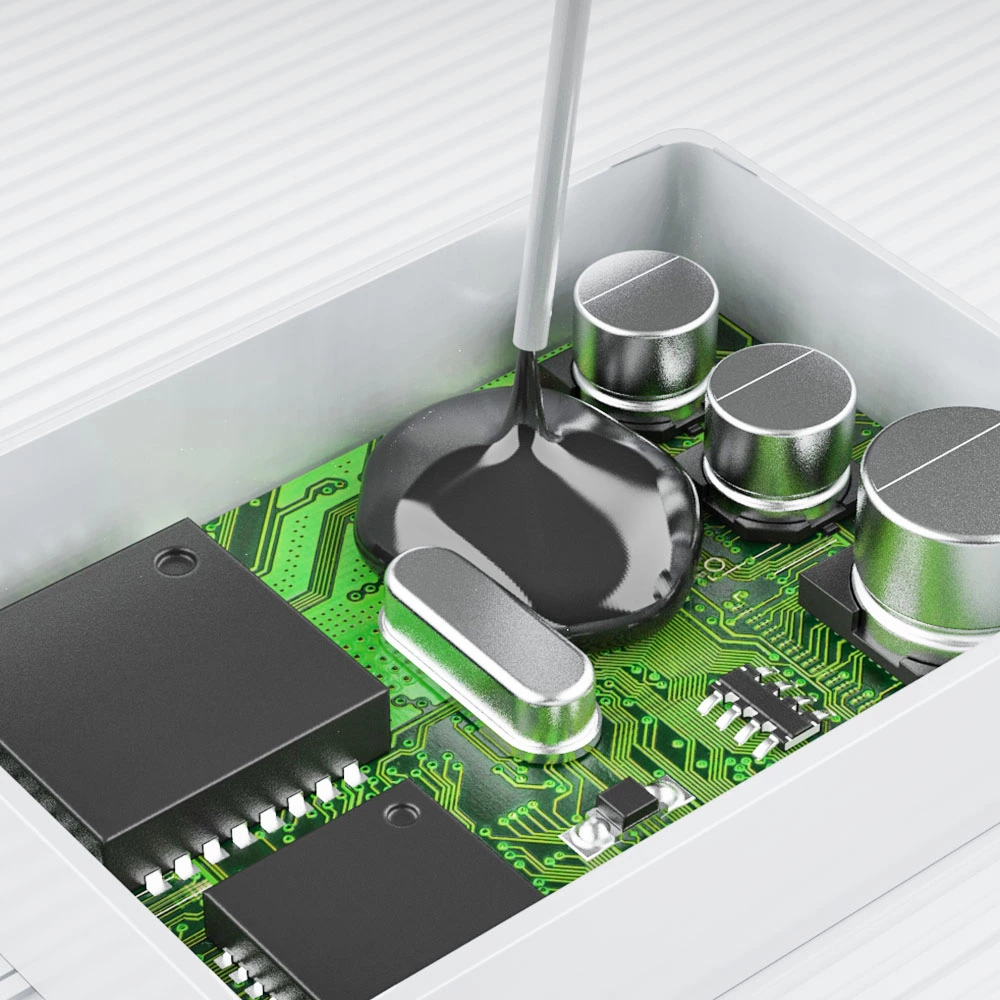

5. Applying Thermal Potting Compound Evenly: Carefully pour or inject the degassed thermal potting compound into the designated areas of the electric motor, ensuring complete and uniform coverage of the components requiring thermal management and protection.

6. Curing Thermal Potting Compound for Optimal Performance: Allow the thermal potting compound to cure fully according to the manufacturer's recommendations. Proper curing is essential for achieving the desired thermal conductivity, mechanical strength, and other properties.

7. Inspecting and Testing Thermally Potted Motors: After curing, inspect the potted areas for any voids, cracks, or inconsistencies. Perform thermal and electrical tests to verify the effectiveness of the thermal potting compound application.

Important Considerations:

-

Handle thermal potting compounds with care, avoiding skin and eye contact. Use appropriate personal protective equipment.

-

Store and use thermal potting compounds according to the manufacturer's guidelines, paying attention to temperature and humidity requirements.

-

Dispose of waste thermal potting compound in compliance with local environmental regulations.

A well-executed thermal potting process is critical for maximizing the heat dissipation capabilities and ensuring the long-term performance and reliability of electric motors.

The Effect of Adding Powder Fillers on Thermal Potting Compound Properties

Incorporating powder fillers into thermal potting compounds can significantly influence their properties, particularly thermal conductivity, consistency, and viscosity. The specific changes depend on factors such as the type, size, shape, and loading level of the filler, as well as its interaction with the base resin.

Impact on Thermal Conductivity and Consistency:

-

Increased Thermal Conductivity: The primary reason for adding powder fillers to thermal potting compounds is often to enhance their thermal conductivity. Certain fillers, such as aluminum oxide, boron nitride, and aluminum nitride, have significantly higher thermal conductivity than typical potting resins.

-

Changes in Consistency: The addition of powder fillers generally increases the consistency of the thermal potting compound, making it thicker and less flowable. The degree of thickening depends on the filler loading and particle characteristics.

Changes in Viscosity with Powder Incorporation:

-

Increased Viscosity: Similar to consistency, the viscosity of the thermal potting compound typically increases with the addition of powder fillers. Higher filler loadings lead to higher viscosity, which can affect the ease of application.

-

Thixotropic Behavior: Some powder fillers can impart thixotropic behavior to the thermal potting compound, meaning its viscosity decreases under shear stress (e.g., during mixing or application) and recovers over time when the stress is removed.

Other Effects of Fillers on Thermal Potting Compound:

-

Density: Adding high-density fillers will increase the overall density of the thermal potting compound.

-

Mechanical Properties: The inclusion of fillers can affect the mechanical strength, hardness, and abrasion resistance of the cured thermal potting compound. The type and amount of filler will determine the extent of these changes.

-

Settling: If the density of the filler is significantly different from the resin, settling of the filler particles may occur over time, especially in low-viscosity compounds. Proper formulation and mixing can help mitigate this.

Optimizing the type and amount of powder filler in thermal potting compounds is crucial for achieving the desired balance of thermal conductivity, viscosity, processability, and mechanical properties for specific electric motor applications. Careful experimentation and material characterization are often required.