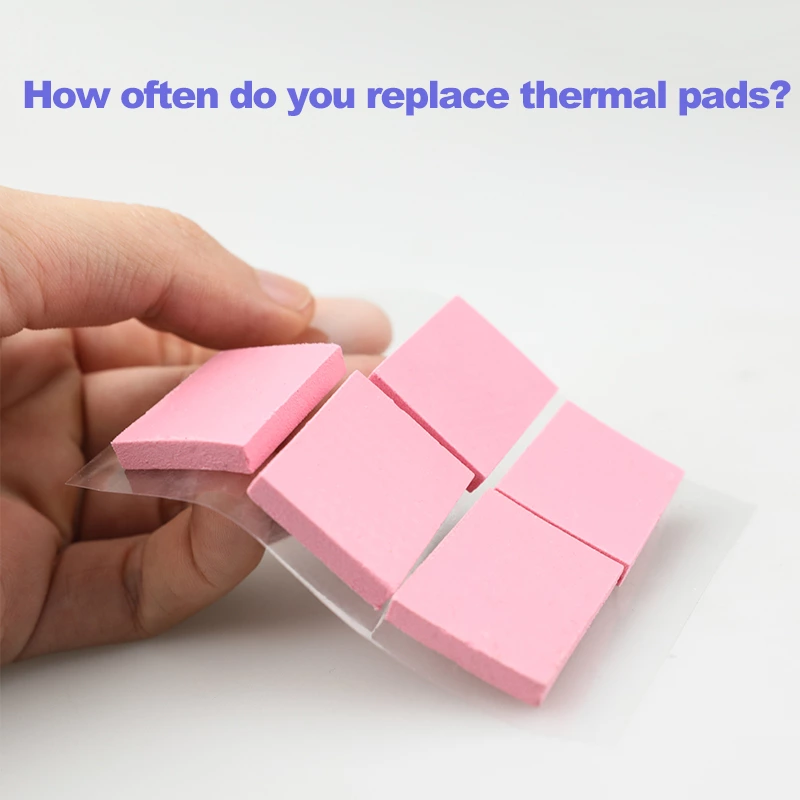

In the thermal design of modern electronic products, thermal pads play a crucial role. They efficiently transfer heat from the heat source to the cooling module, ensuring stable operation and prolonged lifespan of the devices. However, like all materials, the thermal efficiency of thermal pads will gradually decrease over time, leading users to question: Do thermal pads need replacing after use? And how often should they be replaced?

Do Thermal Pads Need Replacing?How Often?

Deep Dive into Thermal Pad Lifespan: How Often Should You Replace Them to Ensure Optimal Heat Dissipation?

The answer is definitely yes; thermal pads need to be replaced periodically to ensure their continuous and efficient heat dissipation performance. Although thermal pads have significant advantages in performance and lifespan compared to traditional thermal grease, such as being less prone to volatilization and aging, with a theoretical lifespan of up to ten years, this does not mean they can be used indefinitely.

The Replacement Cycle of Thermal Pads: The Influence of Multiple Factors

The actual replacement cycle of thermal pads is not fixed and is influenced by a combination of factors:

- Product Design and Operating Environment: The power density, cooling requirements, and operating environment (temperature, humidity, etc.) of different electronic products will directly affect the aging speed of thermal pads. Harsh environments such as high temperature and high humidity will accelerate the oxidation and performance degradation of thermal pads.

- Production Process and Material Quality: As you mentioned, differences exist in the production process standards, raw material quality, and technological development levels of different companies. This directly determines the initial performance and lifespan of thermal pads. High-quality thermal pads typically have a longer lifespan and more stable thermal performance.

- Changes in Material Properties Over Time: Even high-quality thermal pads will experience a gradual decline in their key properties, such as thermal resistance, thermal conductivity, and voltage resistance, over time during use. This is a natural aging process of the material that cannot be completely avoided.

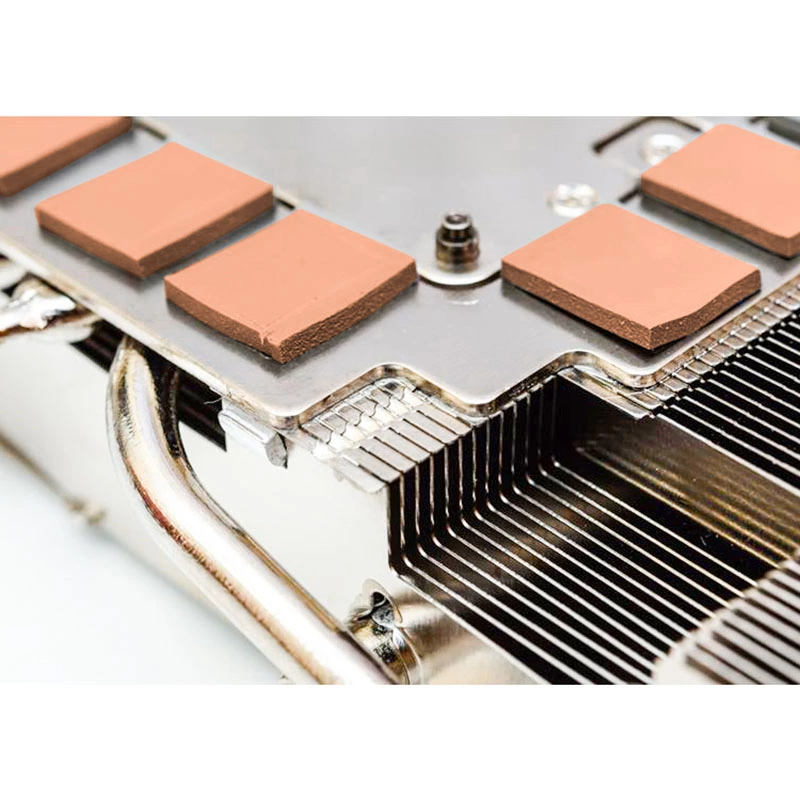

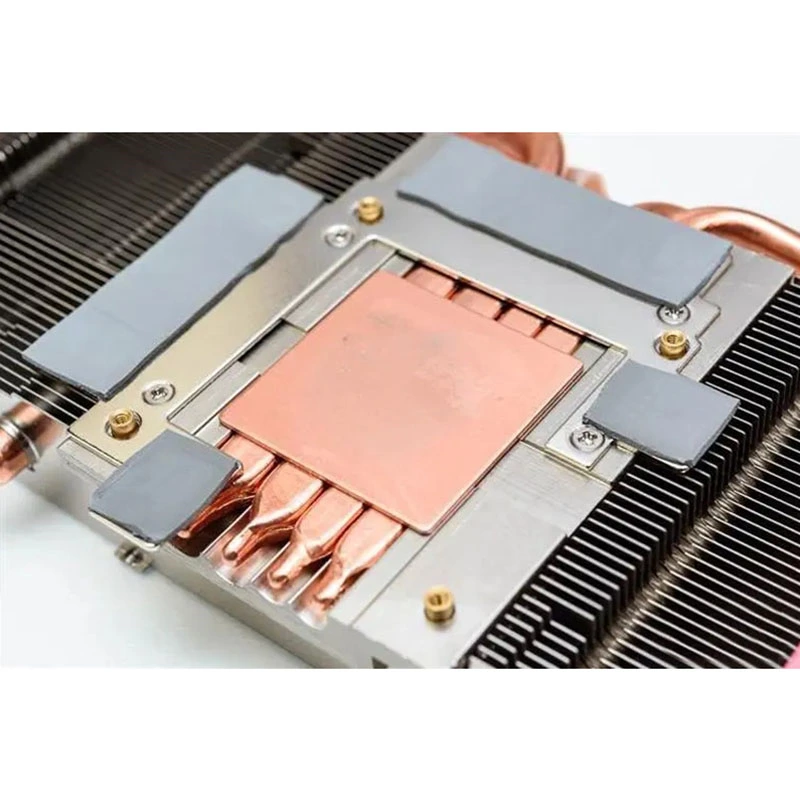

- Usage and Installation Methods: Improper usage environments and installation methods, such as unclean surfaces or uneven pressure, can lead to oxidation, cracking, hardening, or even blackening of thermal pads after prolonged use. These issues will severely affect their thermal performance and shorten their effective lifespan.

fehonda Professional Advice: Regular Replacement for Prevention

Although the theoretical lifespan of thermal pads can be quite long, from the perspective of ensuring the long-term stable operation of electronic devices, fehonda recommends a preventive replacement of thermal pads approximately every five years of device use.

This is because even if the thermal pad has not completely failed after five years, its thermal and electrical insulation performance may have declined. Prolonged use may increase the risk of device overheating and failure. Replacing them in advance can effectively avoid these potential problems, ensuring optimal device performance and extending its overall lifespan.

The Importance of Choosing High-Quality Thermal Pads

When purchasing thermal pads, it is crucial to choose reputable manufacturers with strong technical capabilities. For example, fehonda, with over ten years of experience in the research, production, and sales of thermal interface materials, has significantly improved the service life and reliability of its thermal pads, far exceeding the industry average of 3-5 years. fehonda's products are mass-produced in strict accordance with automotive industry standards, ensuring excellent quality and consistency.

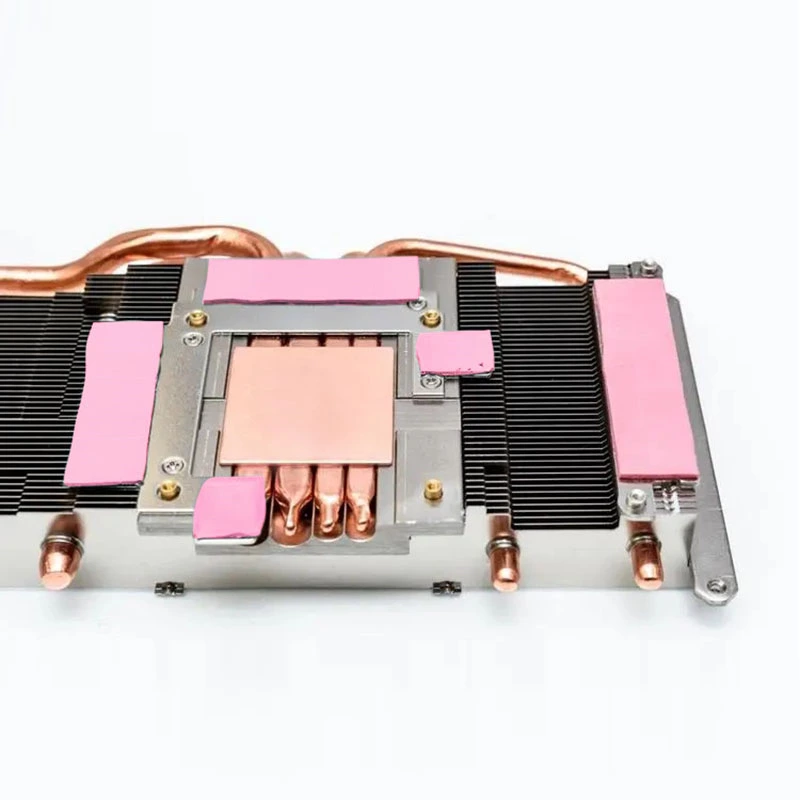

Convenient Replacement and Maintenance

The replacement process for thermal pads is relatively simple. Just carefully remove the old thermal pad, clean the contact surfaces, attach a new thermal pad of the same specifications, and refasten it with screws or buckles. This provides great convenience for device maintenance and upkeep.

Conclusion

As a crucial component for heat dissipation in electronic devices, although thermal pads have a relatively long lifespan, regular replacement is necessary to ensure the long-term stable operation and optimal thermal performance of the devices. our recommends replacing thermal pads approximately every five years based on the actual usage of the device and the manufacturer's recommendations. Choosing high-quality products from reliable suppliers like fehonda will provide a more dependable guarantee for your device's cooling system.

We hope this article has answered your questions. If you have any further inquiries regarding the selection and use of thermal pads, please feel free to visit our website at fehonda.com or contact our professional team. We will be happy to assist you!