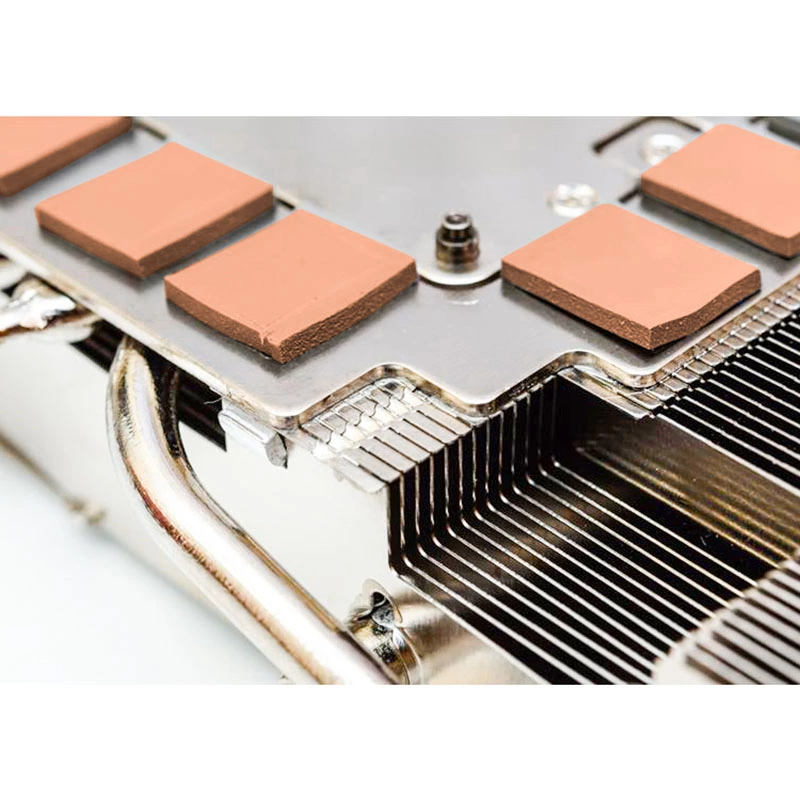

In the thermal management of electronic devices, the thermal conductive pad plays a vital role. It effectively fills the uneven gaps between electronic components and heat sinks, optimizing the heat transfer pathway. However, engineers and procurement professionals often face the question: is a thicker thermal conductive pad always better, or is thinner the way to go?

How Thermal Pad Thickness Impacts Performance in Electronic Cooling

The truth is, there's no one-size-fits-all answer. The optimal thickness selection depends entirely on the specific application scenario and cooling requirements. This article, brought to you by FEHONDA, will delve into the relationship between thickness and performance across various aspects, including thermal resistance, gap filling capability, compression characteristics, mechanical adaptability, and installation convenience, helping you make a more informed and scientific decision.

The Core Function of Thermal Conductive Pads - FEHONDA Insights

FEHONDA highlights the primary roles of thermal conductive pads:

✅ Filling Air Gaps: Air has an extremely low thermal conductivity (approximately 0.026 W/m·K). Without a thermal pad to fill these gaps, heat transfer efficiency will be significantly reduced. ✅ Reducing Contact Thermal Resistance: By optimizing the heat dissipation pathway, thermal pads enable smoother heat transfer to the heat sink. ✅ Buffering Vibration and Enhancing Reliability: Especially in applications like automotive electronics and industrial equipment, thermal pads can provide a degree of vibration damping, preventing mechanical stress from damaging electronic components.

However, the thermal pad itself introduces some thermal resistance, and this resistance is closely related to its thickness. Therefore, the choice of thickness is paramount.

The Relationship Between Thickness and Thermal Performance

The thermal resistance (Rθ) can be calculated using the following formula:

Rθ = t / (k * A)

Where:

- Rθ = Thermal Resistance (K·cm²/W)

- t = Thermal Pad Thickness (cm)

- k = Thermal Conductivity (W/m·K)

- A = Contact Area (cm²)

✅ Conclusion from FEHONDA:

Increasing the thickness of a thermal pad will increase its thermal resistance, thereby reducing heat transfer efficiency. Therefore, in scenarios with high cooling demands, it's crucial to choose the thinnest possible thermal pad with a high thermal conductivity to minimize the impact of thermal resistance on cooling performance.

However, FEHONDA also emphasizes that an excessively thin thermal pad may lead to poor contact and an inability to fill larger gaps, resulting in trapped air layers that hinder heat dissipation. Thus, selecting the appropriate thickness requires striking a balance between thermal resistance and gap filling capability.

Advantages and Suitable Applications of Thicker Thermal Pads (>1mm)

✅ Advantages of Thicker Thermal Pads (as observed by FEHONDA):

- Strong Gap Filling Capability: Suitable for larger gaps (e.g., above 0.5mm), effectively compensating for uneven contact surfaces.

- Buffering Mechanical Pressure: Provides additional protection for vibration-sensitive equipment, such as automotive electronics, drones, and power modules.

- High Tolerance for Installation Errors: Suitable for mass production where component assembly tolerances may be larger.

◆ Suitable Applications (recommended by FEHONDA):

- Large Gap Heat Dissipation (e.g., IGBT modules, power modules, communication base stations)

- High Vibration Environments (e.g., automotive electronics, railway transportation equipment, drones, power batteries)

- Rough Surface Contact (e.g., industrial equipment with rough heat sink surfaces)

Advantages and Suitable Applications of Thinner Thermal Pads (<0.5mm)

✅ Advantages of Thinner Thermal Pads (according to FEHONDA's expertise):

- Low Thermal Resistance, High Heat Transfer Efficiency: Thinner pads offer a shorter heat conduction path, improving heat dissipation efficiency.

- Suitable for High-Performance Cooling Solutions: Ideal for scenarios requiring low thermal resistance and high cooling efficiency, such as CPUs, GPUs, and 5G base stations.

- Suitable for Tight Assemblies: Precision electronic devices often require thinner thermal materials to ensure proper fit.

◆ Suitable Applications (identified by FEHONDA):

- High-Power Chip Cooling (e.g., CPUs, GPUs, LED light sources)

- Ultra-Thin Electronic Devices (e.g., smartphones, laptops, VR devices)

- High-Precision Assembly Requirements (e.g., servers, storage devices, optical instruments)

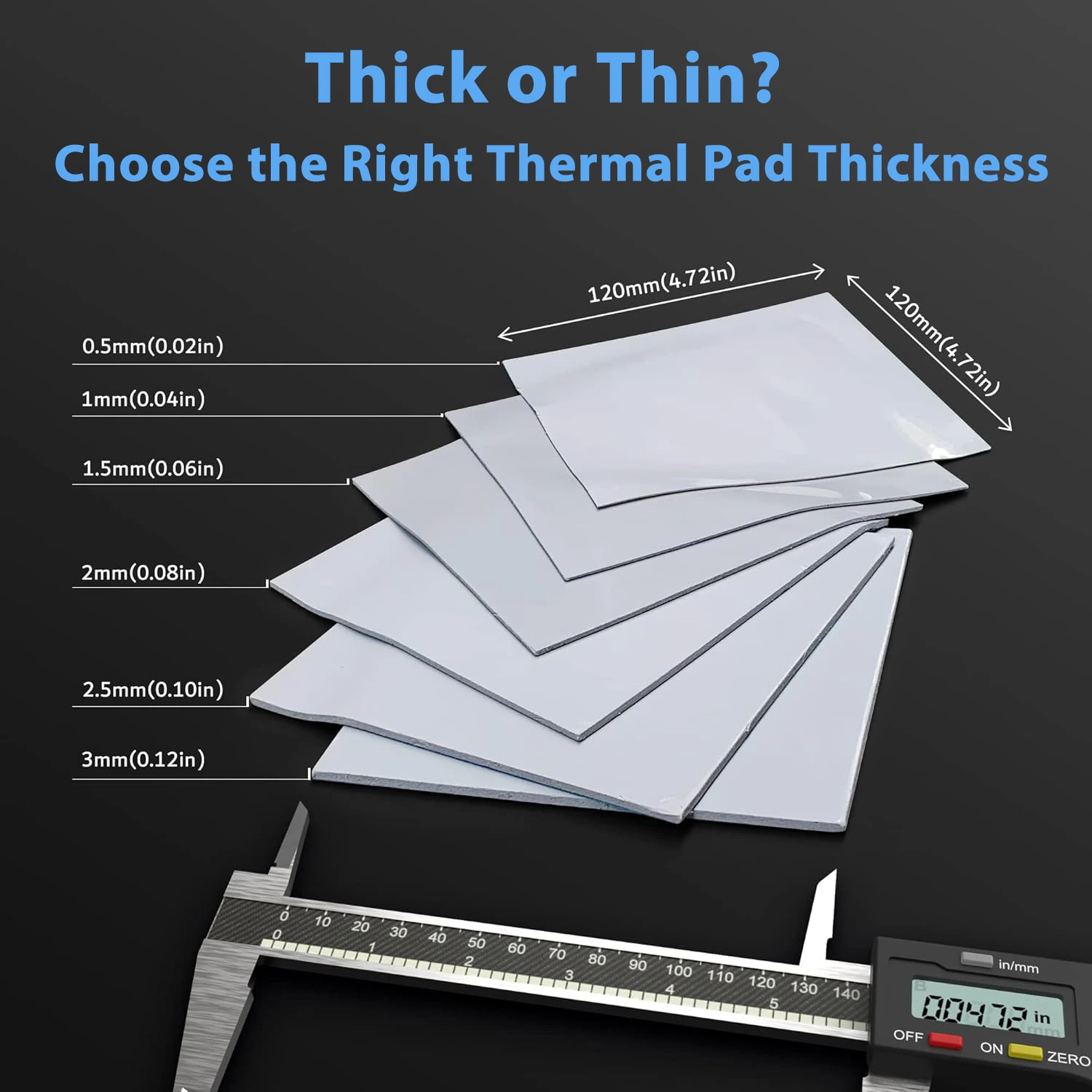

Key Decision Factors: How to Choose the Right Thickness - A FEHONDA Guide

When selecting the thickness of a thermal conductive pad, FEHONDA recommends considering the following comprehensive factors:

| Factor | Thicker Thermal Pads (>1mm) | Thinner Thermal Pads (<0.5mm) |

|---|---|---|

| Thermal Efficiency | Lower (Higher Thermal Resistance) | Higher (Lower Thermal Resistance) |

| Gap Filling Capability | Strong (Suitable for Large Gaps) | Weak (Requires Precise Assembly) |

| Mechanical Buffering | Excellent | General |

| Installation Tolerance | High (Suitable for Mass Production) | Low (Suitable for Precision Assembly) |

| Typical Applications | Industrial Equipment, Automotive Electronics | Consumer Electronics, High-Power Chips |

FEHONDA's Recommended Selection Steps:

- Measure the Gap: Use a thickness gauge to accurately determine the actual gap in your device, avoiding the selection of excessively thick or thin pads.

- Evaluate Cooling Requirements: For high-power devices, prioritize thinner pads to minimize thermal resistance. For large gaps or vibration-prone environments, choose thicker pads for better contact and cushioning.

- Conduct Actual Testing: Different thicknesses of thermal pads may perform differently on specific devices. FEHONDA recommends conducting temperature rise tests to identify the optimal solution.

Common Misconceptions and Professional Advice from FEHONDA

❌ Misconception 1: Thicker Thermal Pads are Always Better

- FEHONDA Debunks: Some believe that increasing the thickness of a thermal pad will enhance cooling. In reality, increased thickness leads to higher thermal resistance, hindering heat dissipation efficiency.

- FEHONDA's Correct Approach: Always aim to choose a thermal pad that is thin enough to minimize thermal resistance while still completely filling the gap.

❌ Misconception 2: Lower Hardness is Always Better

- FEHONDA Clarifies: While lower hardness pads conform more easily to surfaces, excessively soft pads can be compressed too thinly under pressure, negatively impacting thermal performance.

- FEHONDA's Recommended Practice: Select a hardness level appropriate for the assembly pressure (Shore 00 30-50 is a common and often suitable range).

✅ FEHONDA's Professional Advice:

- Prioritize High Thermal Conductivity Materials: If a thicker thermal pad is necessary, opt for products with a thermal conductivity of 6 W/m·K or higher to minimize thermal resistance.

- Consider Multi-Layer Solutions: If a single layer of thermal pad cannot meet the requirements, consider stacking multiple thinner pads. This can reduce overall thermal resistance and improve adaptability.

Conclusion: Thickness Selection Depends on Matching the Needs - A FEHONDA Perspective

Choosing the thickness of a thermal conductive pad requires a comprehensive consideration of the device's actual needs, cooling capacity, and installation conditions, as emphasized by FEHONDA:

✔ Choose Thicker Pads For: Devices with large gaps, high vibration environments, and high assembly tolerances. ✔ Choose Thinner Pads For: Applications demanding high thermal efficiency, tight assemblies, and precision electronic devices.

Ultimately, FEHONDA believes that thorough testing and verification are key to ensuring the optimal thermal management solution. We hope this analysis empowers you to make more informed decisions when selecting the appropriate thermal conductive pad thickness, thereby improving the cooling efficiency and reliability of your electronic devices!