In the intricate world of computer hardware, some of the most crucial components are also the most unassuming. Thermal paste is a prime example—a small dab of material that plays an outsized role in keeping your powerful PC components cool and running optimally. This comprehensive guide will delve into the science of how thermal paste works, why it's indispensable, how to choose the right type, and the best practices for application and maintenance.

How Thermal Paste Works Your Guide to PC Component Cooling

Section 1: The Unsung Hero: Understanding Thermal Paste in Your PC

Subsection 1.1: What is Thermal Paste and Why Is It Absolutely Essential?

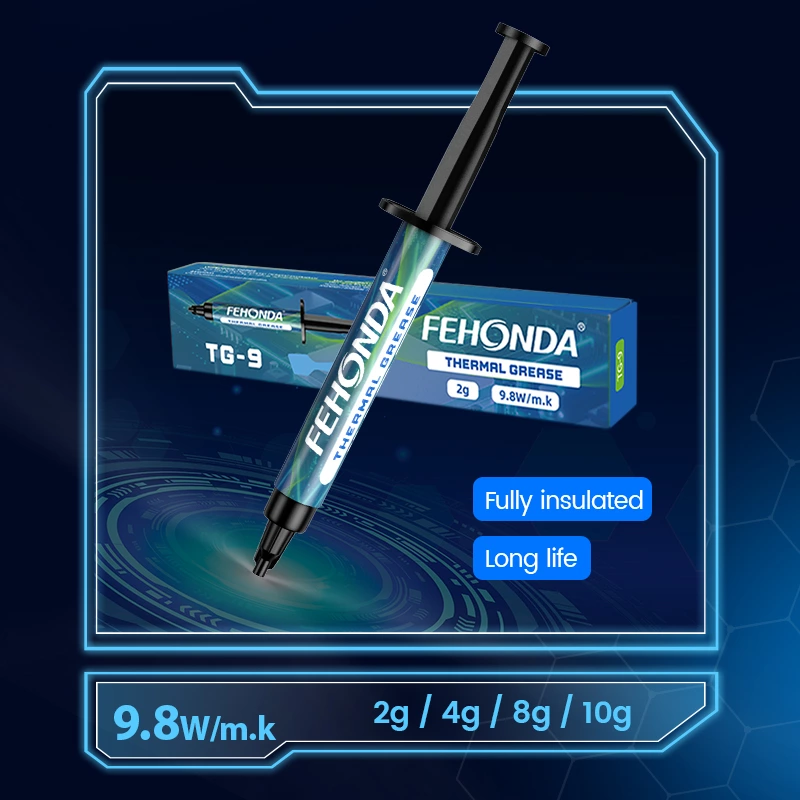

Thermal paste, also known by various names such as thermal compound, thermal grease, heat paste, CPU grease, or Thermal Interface Material (TIM), is a substance applied to a computer's processor before a cooling solution is installed. Its primary and critical function is to improve the efficiency of heat transfer between a heat-generating component, like the Central Processing Unit (CPU) or Graphics Processing Unit (GPU), and its dedicated cooling device, such as a heatsink or a waterblock. Companies like Fehonda offer a range of thermal paste products designed for this purpose, such as their 8.5W/mK Premium Performance paste or the TR50L series.

For most high-performance computer components, thermal paste is not an optional accessory but an absolute necessity. Without it, or if it's applied incorrectly, the heat generated by the processor cannot be effectively drawn away. This can lead to components rapidly overheating, resulting in a cascade of problems including performance degradation (known as thermal throttling, where the component slows itself down to reduce heat output), system instability, and in worst-case scenarios, permanent physical damage to the hardware. The seemingly minor cost and quantity of thermal paste belie its significant impact; this small application is fundamental to the stability, performance, and longevity of expensive core components like CPUs and GPUs, making it a true unsung hero in any PC build.

Subsection 1.2: Defining Key Hardware: The Players in the Thermal Drama

To fully appreciate how thermal paste works, it's important to understand the key components involved in the heat generation and dissipation process:

- Central Processing Unit (CPU): Often described as the "brain" of the computer, the CPU is responsible for processing instructions and performing calculations. Modern CPUs execute an immense volume of operations per second, which inherently generates a substantial amount of heat. Efficient cooling is paramount for a CPU to operate at its peak efficiency.

- Graphics Processing Unit (GPU): Similar to the CPU, the GPU handles graphics-intensive tasks, such as gaming, video editing, and 3D rendering. It is also a major heat producer within a computer system. While many graphics cards come with their thermal solutions (cooler and paste) pre-installed, the underlying principles of heat transfer and the role of thermal paste remain the same.

- Integrated Heat Spreader (IHS): This is the metal "lid" or cover on top of the CPU. The IHS serves two main purposes: it protects the delicate processor die underneath, and it acts as the first surface to draw heat away from the die, spreading it out for more effective transfer to the CPU cooler. Thermal paste is applied directly onto the top surface of the IHS.

- CPU Cooler / Heatsink: This is the device responsible for drawing heat away from the CPU and dissipating it. CPU coolers can be air-based (using a metal heatsink with fins and a fan) or liquid-based (using a waterblock, pump, radiator, and fans).

- Base-Plate (Air Cooler): The flat metal base of an air cooler that makes direct contact with the CPU's IHS (via thermal paste). Heat is transferred from the IHS, through the thermal paste, to this base-plate, and then up into the heatsink's fins to be dispersed by a fan.

- Waterblock (Liquid Cooler): In liquid cooling systems (either All-in-One units or custom loops), the waterblock is the component that mounts onto the CPU's IHS. It transfers heat from the IHS, through the thermal paste, into the liquid coolant circulating within the system, which then carries the heat to a radiator for dissipation.

Understanding these components allows for a clearer visualization of the physical path heat must travel. Heat originates in the CPU or GPU die, moves to the IHS (in the case of most CPUs), and then must be transferred to the cooler. Thermal paste is the critical material that bridges the gap at this IHS-to-cooler interface, ensuring an efficient thermal pathway.

Section 2: The Heat Challenge: Why Computers Need Help Cooling Down

The demand for ever-increasing processing power means that modern computer components are pushed to their limits, and a primary byproduct of this high performance is heat.

Subsection 2.1: The Science of Heat Generation in Computer Components

Modern CPUs and GPUs are marvels of engineering, containing billions of microscopic transistors that switch on and off at incredible speeds to execute complex operations. This intense electrical activity, occurring within the transistors and other integrated circuit components, encounters electrical resistance. This resistance is the fundamental reason why these components generate heat. In fact, CPUs and power components are sometimes described as highly inefficient parts that waste a significant amount of energy in the form of heat.

If this generated heat is not managed effectively, it can lead to severe consequences. Excess heat rapidly degrades the performance of semiconductor devices; a common effect is "thermal throttling," where the component automatically reduces its operating speed to lower heat production and prevent damage. In extreme cases, uncontrolled heat can lead to system crashes or even catastrophic, irreversible failure of the component. The relentless drive for faster and more powerful processors inherently exacerbates this heat problem. As performance demands rise—higher clock speeds, more cores, increased transistor density—so does the amount of heat generated, making effective thermal management solutions, including thermal paste, increasingly critical.

Subsection 2.2: Microscopic Imperfections: The Invisible Barrier to Cooling

One might assume that the polished metal surface of a CPU's IHS and the base of a high-quality CPU cooler are perfectly flat and smooth. To the naked eye, they often appear to be. However, at a microscopic level, these surfaces are far from perfect. They possess tiny, invisible imperfections such as pits, grooves, valleys, and other irregularities.

These microscopic imperfections are an unavoidable consequence of the manufacturing and machining processes used to create these components. Even with the most advanced, bleeding-edge tools and techniques, achieving atomic-level flatness across the entire surface area of an IHS or cooler base in mass production is practically impossible. This inherent limitation means that when these two "smooth" surfaces are pressed together, they don't make perfect, uniform contact.

Subsection 2.3: Air Gaps: The Enemy of Efficient Heat Transfer

The direct consequence of these microscopic surface imperfections is the creation of tiny air gaps when the CPU's IHS and the cooler's base are brought into contact. These air pockets, though minuscule, form an insidious barrier to efficient heat transfer.

Air is an exceptionally poor conductor of heat; in fact, it's a thermal insulator. The thermal conductivity of air is roughly 0.026 Watts per meter-Kelvin (W/mK), which is orders of magnitude lower than that of thermally conductive materials like copper (around 200-400 W/mK) used in heatsinks. These air-filled gaps significantly impede the flow of heat from the hot CPU to the cooler, effectively acting as an insulating layer. The negative impact of these air gaps is not minor; it's a primary bottleneck. The efficiency of even a high-end, expensive CPU cooler can be severely crippled by these invisible air pockets if thermal paste isn't used, or is poorly applied, highlighting the leverage thermal paste has on the entire cooling system's performance.

Section 3: How Thermal Paste Works: Bridging the Thermal Gap

Thermal paste is engineered specifically to overcome the challenges posed by microscopic surface imperfections and insulating air gaps.

Subsection 3.1: The Core Mechanism: Filling Voids and Enhancing Contact

The fundamental working principle of thermal paste is remarkably simple yet profoundly effective. It is a viscous, thermally conductive material designed to flow into and fill the microscopic air gaps and surface irregularities present on the CPU's IHS and the cooler's contact plate. Fehonda's TR50L paste, for example, is described as having low-viscosity allowing it to easily fill microscopic abrasions and channels for peak thermal transfer. By filling these voids, the thermal paste displaces the trapped air, which, as established, is a poor thermal conductor.

This action creates a more continuous and uniform thermal interface between the heat-generating component and the heatsink. It maximizes the effective contact area through which heat can travel, ensuring that the two surfaces are thermally coupled much more efficiently than they would be with air in between. It's important to understand that thermal paste itself doesn't actively "cool" anything. Instead, it acts as a crucial facilitator—a "thermal bridge"—that enables the actual cooling device (the heatsink or waterblock) to perform its job effectively by creating an efficient pathway for heat to travel from the source to the cooler.

Subsection 3.2: Improving Thermal Conductivity: From Component to Cooler

Thermal paste achieves its goal because it possesses significantly higher thermal conductivity than air. While it's generally not as conductive as the pure metals like copper or aluminum that make up the bulk of heatsinks, it is vastly superior to the insulating properties of air. By replacing the air in the microscopic gaps with this more thermally conductive material, the thermal paste effectively reduces the thermal resistance at the interface between the CPU and the cooler.

This reduction in thermal resistance allows heat to flow more easily and efficiently from the CPU's IHS to the base plate of an air cooler or the waterblock of a liquid cooler. The ideal application of thermal paste results in a very thin layer that only fills the gaps and imperfections. The goal is to maximize direct metal-to-metal contact where the surfaces are truly flat enough to touch, with the paste handling the unavoidable microscopic valleys and crevices. An excessively thick layer of thermal paste can become counterproductive, as the paste itself (while better than air) still offers more thermal resistance than direct contact between the metals of the IHS and cooler.

Subsection 3.3: The Journey of Heat: IHS to Heatsink/Waterblock

Let's trace the journey of heat to see where thermal paste fits in. Heat is generated within the tiny transistors of the CPU die. This heat then transfers to the Integrated Heat Spreader (IHS). From the IHS, the heat must cross the interface to the base of the CPU cooler (either an air cooler's base-plate or a liquid cooler's waterblock). This is precisely where thermal paste plays its critical role, ensuring an efficient thermal bridge across this junction. Once the heat reaches the cooler's base, it is then conducted into the heatsink fins (for air coolers) or into the liquid coolant (for liquid coolers), where it is finally dissipated into the surrounding air, often with the assistance of fans.

Any inefficiency at the thermal paste interface creates a significant bottleneck for the entire cooling system. Even the most powerful and expensive CPU cooler will underperform if the heat generated by the CPU cannot effectively reach it due to poorly applied, degraded, or missing thermal paste. Thus, proper thermal paste application is essential for unlocking the full potential of the entire cooling solution and maintaining optimal component temperatures.

Section 4: Decoding Thermal Paste: Composition and Key Properties

The effectiveness of thermal paste stems from its unique composition and specific physical properties. Understanding these can help in selecting the most appropriate type for a given application.

Subsection 4.1: Common Ingredients: What Makes Thermal Paste Effective?

Thermal paste is typically a composite material, consisting of two main components: a polymerizable liquid matrix (which acts as a base or binder) and thermally conductive filler particles.

- Base Materials: The liquid matrix is often a silicone-based compound or a carbon-based solution. Silicone is frequently chosen for its excellent thermal stability (resistance to breaking down under heat) and flexibility, allowing it to conform to surfaces. Fehonda, for instance, utilizes silicone as a main raw material in some of their pastes, like their 8.5W/mK product and the TR50L. Synthetic oils can also serve as the base material in some formulations.

- Conductive Fillers: These are the workhorses of thermal paste, as they are primarily responsible for enhancing its thermal conductivity. Common types of filler particles include:

- Metal particles: Finely ground particles of metals like silver, aluminum, or copper are used in many high-performance pastes due to their excellent inherent thermal conductivity.

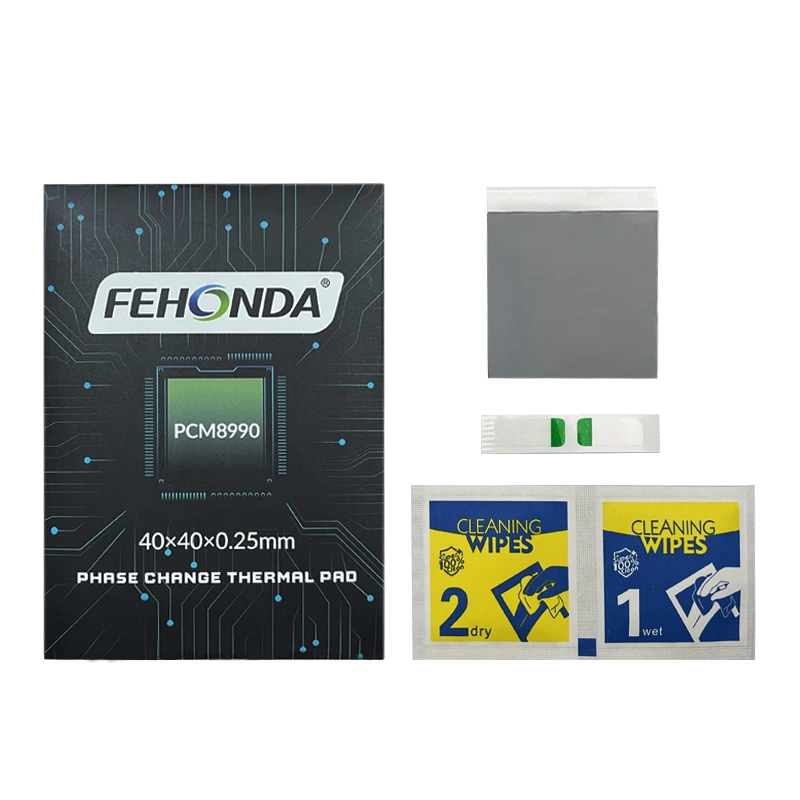

- Ceramic particles: Compounds such as zinc oxide, aluminum oxide, or boron nitride are common ceramic fillers. They offer good thermal conductivity and are typically electrically non-conductive, making them a safer option. Fehonda's TR50L thermal paste is described as a premium Zinc Oxide based thermal compound.

- Carbon particles: Various forms of carbon, including graphite, graphene, or even diamond powder, are used in some advanced thermal pastes. Diamond, in particular, has exceptionally high thermal conductivity.

To maximize the paste's ability to conduct heat, the concentration of these filler particles (filler loading) can be very high, often reaching 70-80% by mass. The choice of base and filler materials involves a complex engineering trade-off, balancing factors like thermal performance, electrical conductivity (or lack thereof), viscosity for ease of application, long-term stability under temperature cycling, and overall cost. There isn't a single "perfect" ingredient; manufacturers like Fehonda formulate pastes to optimize for a specific set of desired characteristics and target applications, offering products with varying thermal conductivities such as 8.5W/mK and 14.8W/mK.

Subsection 4.2: Understanding Thermal Conductivity (W/mK)

Thermal conductivity is a fundamental property that quantifies a material's ability to conduct or transfer heat. It is typically measured and expressed in units of Watts per meter-Kelvin, often written as W/(m·K) or W/mK.

A higher W/mK value indicates that the material is more efficient at transferring heat. For context, the base matrix of a thermal paste (without fillers) has very low thermal conductivity, around 0.17–0.3 W/(m·K). The addition of conductive fillers significantly boosts this value. General-purpose ceramic pastes might achieve around 4 W/(m·K), while silver-based compounds can range from 3 to 8 W/(m·K) or even higher. Brands like Fehonda offer pastes with specified thermal conductivities, for example, their Premium Performance paste at 8.5W/mK and their TR50L at 14.8W/mK. The most advanced liquid metal pastes can exceed 13 W/(m·K), with some specialized formulations claiming much higher figures. These values should be compared to the extremely low thermal conductivity of air (approximately 0.026 W/(m·K)) and the very high conductivity of metals like copper (around 200-400 W/(m·K)).

While a higher W/mK rating is generally desirable, it's not the sole determinant of real-world cooling performance. The actual effectiveness of a thermal paste application also depends heavily on the thickness of the applied layer, the quality of the mating between the CPU and cooler surfaces, and the clamping pressure exerted by the cooler's mounting mechanism. A paste with an exceptionally high W/mK rating, if applied poorly (e.g., too thick or with air bubbles), might perform worse than a paste with a more moderate W/mK rating that is applied perfectly. This leads to the broader concept of thermal impedance, which considers not just the material's conductivity but also the interface resistances. Fehonda's TR50L, for instance, is noted for its ultra-low thermal impedance.

Subsection 4.3: Other Important Properties: Viscosity and Electrical Conductivity

Beyond thermal conductivity, two other properties are crucial when considering thermal pastes: viscosity and electrical conductivity.

-

Viscosity: This term describes the paste's thickness or its resistance to flow. Viscosity significantly impacts the ease of application and the paste's ability to spread evenly to form a thin, uniform layer. Fehonda thermal pastes, for example, list viscosity ranges such as 25-120(103) or 970 poise for their TR50L product, with the TR50L specifically noted for its low-viscosity that allows it to easily fill microscopic abrasions.

- A paste that is too viscous (too thick) can be difficult to spread, may not flow readily into the smallest microscopic imperfections, and can even lead to the trapping of air bubbles if not applied carefully.

- Conversely, a paste that is too fluid (low viscosity) might be challenging to control during application, could flow out from between the CPU and heatsink over time (especially under pressure or with vibration), and may dry out faster if it relies on volatile solvents for its fluidity. The ideal viscosity allows for easy application, good spreadability under the cooler's pressure, and the formation of a consistent, thin layer that effectively fills all gaps. Viscosity is not just about user convenience; it's directly linked to the paste's ability to achieve its primary function of forming a complete, thin, air-free thermal bridge.

-

Electrical Conductivity: This property indicates whether the thermal paste can conduct electricity. For safety reasons, most thermal pastes are specifically designed to be thermally conductive but not electrically conductive.

- Metal-based pastes, particularly those containing silver or other metallic particles, and especially liquid metal pastes, can be electrically conductive. This poses a significant risk: if any of this conductive paste accidentally spills or spreads onto the delicate circuitry of the motherboard, CPU socket, or other components, it can cause short circuits, leading to malfunction or permanent hardware damage.

- Ceramic-based pastes, and many silicone-based and carbon-based pastes, are formulated to be non-electrically conductive (insulators). Fehonda emphasizes that their thermal pastes, such as the 8.5W/mK version and the TR50L series, are non-conductive and safe for your PC, containing zero volatile compounds. This makes them a much safer choice for most users, especially beginners. The electrical conductivity aspect creates a clear divergence in product categories and target users. Electrically conductive pastes are generally aimed at experienced enthusiasts and overclockers who are seeking maximum thermal performance and are willing to accept the higher application risk. Non-conductive pastes cater to the broader market, prioritizing safety and ease of use, even if their absolute peak thermal conductivity might be slightly lower.

Section 5: A Guide to Thermal Paste Types: Making the Right Choice

The market offers a diverse array of thermal pastes, each with its own characteristics, performance profiles, and ideal use cases. Choosing the right one can seem daunting, but understanding the main categories can simplify the decision.

Subsection 5.1: Overview of Common Thermal Paste Categories

Thermal pastes can be broadly grouped based on their primary conductive fillers and base materials:

- Silicone-based: Often used as a base material for other fillers, silicone pastes are known for their good thermal stability, ease of application, and are generally considered good all-round performers for many standard applications. They are typically electrically non-conductive. Many Fehonda pastes, like their 8.5W/mK and TR50L, use silicone as a main raw material and are non-conductive.

- Carbon-based: These pastes utilize various forms of carbon particles—such as graphite, graphene, or synthetic diamond powder—as their primary conductive filler. Carbon-based pastes, particularly those with diamond or graphene, can offer very high thermal conductivity and are usually electrically non-conductive, making them a high-performance yet safe option. Diamond-infused pastes represent the premium end of this category.

- Ceramic-based: These contain fine ceramic particles, such as zinc oxide, aluminum oxide, or boron nitride, suspended in a base (often silicone or synthetic oil). Ceramic pastes provide a good balance of thermal conductivity, are typically non-electrically conductive (making them very safe), and are often quite affordable. Fehonda's TR50L is a premium Zinc Oxide based thermal compound.

- Metal-based: These pastes incorporate microscopic metal particles, most commonly silver, but sometimes aluminum or copper, to achieve high thermal conductivity. While effective at heat transfer, many metal-based pastes are electrically conductive, requiring careful application to avoid short circuits.

- Liquid Metal: Composed of eutectic alloys (like Galinstan – a mix of gallium, indium, and tin) that are liquid at or near room temperature. Liquid metal pastes offer the highest thermal conductivity currently available, significantly outperforming other types. However, they come with major caveats: they are highly electrically conductive, can be corrosive to aluminum surfaces (meaning they cannot be used with aluminum heatsinks), and are notoriously difficult to apply safely and correctly.

- Hybrid Compounds: Some pastes are marketed as hybrids, aiming to combine the beneficial properties of different material types.

The evolution from basic silicone and ceramic pastes to advanced carbon formulations (like diamond and graphene) and sophisticated liquid metal compounds reflects the continuous demand for superior thermal performance. This demand is driven by the development of increasingly powerful and consequently hotter computer components, creating a sort of miniature technological arms race in the thermal interface material space.

Subsection 5.2: Comparative Overview of Thermal Paste Types

To help visualize the differences and make an informed choice, the following table provides a comparative overview of common thermal paste types:

| Paste Type | Primary Fillers | Typical Thermal Conductivity (W/mK Range) | Electrical Conductivity | Ease of Application | General Durability/Lifespan | Key Pros | Key Cons |

|---|---|---|---|---|---|---|---|

| Silicone-based (General) | Silicone polymers, often with ceramic fillers like Zinc Oxide | 1-4 | No | Easy | Moderate to Long | Safe, affordable, easy to use | Lower thermal conductivity compared to others |

| Ceramic-based (General) | Aluminum Oxide, Zinc Oxide, Boron Nitride | 2-8 | No | Easy | Moderate to Long | Good balance of performance & safety, affordable | Can be outperformed by metal/carbon pastes |

| Fehonda TR50L (Silicone/Zinc Oxide based example) | Silicone, Zinc Oxide | 14.8 | No | Easy (includes stencil/spreader) | Long (high-stability liquid compound) | High thermal conductivity, non-conductive, long service life, application aids | Higher cost than basic pastes |

| Carbon-based (Standard) | Graphite, Carbon fibers | 4-10 | Typically No | Generally Easy | Long | Good performance, often non-conductive, good degradation resistance | Can be slightly more expensive than basic ceramic |

| Carbon-based (Diamond/Graphene) | Diamond powder, Graphene flakes | >10 (Diamond can be much higher) | No | Easy | Very Long | Top non-metallic performance, electrically insulating, excellent stability | Very expensive |

| Metal-based (e.g., Silver) | Silver, Aluminum, or Copper particles | 3-10+ | Yes (Varies, often capacitive) | Moderate (care needed) | Moderate to Long | Very high thermal conductivity | Electrically conductive (risk of shorts), requires careful application |

| Liquid Metal | Gallium-Indium-Tin alloys (Galinstan) | >13 (can be 70+) | Yes (High Risk) | Difficult (high care & prep needed) | Potentially Long (application sensitive) | Absolute best thermal conductivity | Electrically conductive, corrosive to aluminum, very difficult/risky to apply, expensive |

Note: Values for thermal conductivity and lifespan are general estimates and can vary significantly between specific products and brands. Always check manufacturer specifications.

Subsection 5.3: Pros and Cons of Each Type in Detail

Let's delve deeper into the advantages and disadvantages of each thermal paste category:

- Silicone-based Pastes:

- Pros: Generally inexpensive, widely available, easy to apply, and electrically non-conductive, making them safe for beginners. They offer decent thermal stability. Brands like Fehonda offer silicone-based pastes like their 8.5W/mK product and the high-performance TR50L (14.8W/mK), which are also non-conductive and designed for ease of use and long service life.

- Cons: Basic silicone pastes typically offer lower thermal conductivity compared to other types, though advanced formulations like Fehonda's TR50L demonstrate that silicone-based pastes can achieve high performance. Some silicone compounds might experience "outgassing" (release of volatile silicone gas) in specific high-temperature or vacuum environments, which could be an issue if used near sensitive electrical contacts like relays, though this is less of a concern for typical CPU cooling. Fehonda TR50L is noted to contain zero volatile compounds.

- Ceramic-based Pastes:

- Pros: Offer a good balance of thermal performance, safety (non-electrically conductive), and affordability. They are easy to apply and clean, with good thermal stability, making them a popular choice for general PC users and gamers. Fehonda's TR50L, a Zinc Oxide based compound, fits this profile by offering optimal thermal performance while being non-conductive.

- Cons: While good, their thermal conductivity is generally lower than high-end carbon, metal, or liquid metal pastes, though premium ceramic-based options can be very competitive. May not offer significant temperature reductions in very demanding overclocking scenarios.

- Carbon-based Pastes (Standard - e.g., Graphite):

- Pros: Can provide good to very good thermal conductivity, often superior to basic ceramic pastes. They are typically electrically non-conductive and can have a long operational life due to good degradation resistance.

- Cons: Performance can vary; some may be only marginally better than good ceramics, while others approach metal-based performance.

- Carbon-based Pastes (Advanced - e.g., Diamond, Graphene):

- Pros: Offer exceptionally high thermal conductivity for non-metallic pastes, rivaling or even exceeding some metal-based options, while remaining electrically insulating and non-capacitive. They boast excellent stability and longevity.

- Cons: Their primary drawback is high cost due to the expensive filler materials (diamond powder, graphene).

- Metal-based Pastes (e.g., Silver-based):

- Pros: Provide very high thermal conductivity, leading to excellent cooling performance, especially beneficial for overclocking or systems under heavy thermal load.

- Cons: The main disadvantage is their electrical conductivity (and sometimes capacitance). Accidental spillage or spread onto motherboard components can cause short circuits and permanent damage, requiring meticulous application.

- Liquid Metal Pastes:

- Pros: Offer the absolute highest thermal conductivity available, resulting in the lowest possible CPU/GPU temperatures, making them the top choice for extreme overclockers and performance enthusiasts.

- Cons: They come with significant risks and challenges. They are highly electrically conductive. They are corrosive to aluminum, meaning they cannot be used with aluminum heatsinks (many heatsinks use copper bases but aluminum fins; direct contact with any aluminum part must be avoided). Application is very difficult, requiring precision and often protective measures (like conformal coating on nearby components) to prevent disastrous spills. They are also typically the most expensive option. Strictly for experienced and cautious users.

Ultimately, the "best" thermal paste is highly subjective and depends entirely on the individual user's priorities. Factors such as budget, desired thermal performance, tolerance for risk, and level of experience in PC building all play a crucial role in making the right decision. There is no single, universally "best" paste that suits everyone.

Subsection 5.4: Considerations for Specific Use Cases

Matching the thermal paste to the intended application can optimize both performance and safety:

- General PC Use / Office Work: For systems used for everyday tasks like web browsing, document editing, and light media consumption, the thermal demands are relatively low. Standard ceramic-based or basic silicone/carbon pastes are usually more than sufficient, offering a good balance of adequate performance, safety (non-electrically conductive), and cost-effectiveness.

- Gaming Rigs: Gaming PCs place a significant and sustained thermal load on both the CPU and GPU. High-quality ceramic pastes, advanced carbon-based pastes (including diamond-infused options if the budget allows), or even carefully applied metal-based pastes (for users comfortable with the risk) are good choices to ensure better heat dissipation and prevent thermal throttling during intense gaming sessions. For these users, products like Fehonda's TR50L (14.8W/mK) or their 8.5W/mK paste can offer excellent non-conductive options for improved heat transfer.

- Overclocking / Extreme Performance Builds: Enthusiasts who push their components to the limits through overclocking require the best possible thermal transfer to maintain stability and achieve maximum performance. For these users, high-end metal-based pastes or, for the most extreme scenarios and experienced builders, liquid metal pastes are often preferred. High-performance non-conductive pastes, such as Fehonda's 14.8W/mK TR50L, can also be a strong consideration for overclockers who prioritize safety alongside performance. The potential for a few degrees Celsius improvement in temperature can make a difference in achievable clock speeds and stability, justifying the higher cost and accepted risks.

- Laptops / Small Form Factor (SFF) Builds: In compact systems like laptops or SFF PCs, space is at a premium, and component access can be difficult. For these builds, ease of application and non-electrical conductivity are often prioritized to avoid accidental shorts in cramped quarters. Paste stability and longevity also become more important, as reapplication can be a more involved process than in a standard desktop tower. Fehonda pastes, being non-conductive and some offering long service life, are suitable for such applications.

The choice of thermal paste can be viewed as a micro-optimization for many general users, where a basic, well-applied paste will perform adequately. However, for PC enthusiasts, gamers, and overclockers, it becomes a critical tuning parameter, where every degree of temperature reduction can contribute to improved performance, stability, and component longevity.

Section 6: The Art of Application: Ensuring Optimal Thermal Performance

Even the highest quality thermal paste will underperform if not applied correctly. Proper application is an art that balances precision with understanding the material's purpose.

Subsection 6.1: Preparation is Key: Cleaning CPU/GPU and Heatsink Surfaces

Before any new thermal paste is applied, it is absolutely crucial that both the surface of the CPU/GPU's Integrated Heat Spreader (IHS) and the contact surface of the heatsink or cooler base are meticulously cleaned. Any remnants of old thermal paste, dust particles, oils from fingerprints, or other debris must be completely removed.

The recommended cleaning agents are high-purity isopropyl alcohol (90% or higher is ideal) and a lint-free cloth, such as a microfiber cloth or, in a pinch, an unused paper coffee filter. Apply a small amount of alcohol to the cloth and gently wipe the surfaces until they are perfectly clean and shiny. It's important to ensure that the surfaces are completely dry before applying the new paste. Any contamination left on the surfaces can interfere with the new paste's ability to spread evenly, create new air gaps, or reduce its overall thermal effectiveness. Skipping or rushing this cleaning step can significantly negate the benefits of even the most expensive thermal paste.

Subsection 6.2: How Much is Enough? The "Pea-Sized" Rule and Its Variations

One of the most debated aspects of thermal paste application is the quantity. The general consensus and most common recommendation for typical CPUs is to apply a small amount, roughly the size of a grain of rice or a small pea, directly onto the center of the CPU's IHS. For larger CPUs, like some high-end desktop (HEDT) processors or server CPUs with larger IHS dimensions, a slightly larger amount might be necessary, but the principle remains the same: use only what's needed. Some sources even provide specific volume recommendations; for instance, for a 30mm by 30mm CPU, 0.2ml of thermal paste is suggested as sufficient.

The pressure exerted when mounting the CPU cooler will then spread this central deposit of paste outwards, ideally forming a thin, even layer that covers the entire contact area between the IHS and the cooler base. The guiding principle is "less is often more," as long as complete coverage is achieved. The "pea-sized" advice is a useful heuristic, not an exact scientific measurement, because CPU IHS sizes can vary. The underlying goal is to use just enough paste to fill all the microscopic air gaps across the entire contact surface once the paste is spread, without causing excessive overflow when the cooler is mounted.

Subsection 6.3: Common Application Methods and Achieving Even Spread

Several methods are commonly used to apply thermal paste, each with its proponents:

- Center Dot / Pea Method: This is arguably the most popular and frequently recommended method. A single, small dot or pea-sized amount of paste is applied to the center of the IHS. The mounting pressure of the cooler is relied upon to spread the paste evenly.

- Line Method(s): One or more thin, parallel lines of paste are applied across the IHS. Some suggest that a single line method might risk applying too little paste if not judged correctly.

- X / Cross Method: The paste is applied in the shape of an "X" or a cross on the IHS.

- Five Dots Method: This involves placing one dot in the center of the IHS and four smaller dots near each corner.

- Spreading Method (Buttered Toast): With this technique, the user manually spreads a thin, even layer of thermal paste over the entire surface of the IHS using a small, non-metallic spatula, a plastic card (like an old credit card), or a gloved finger before installing the cooler. This method provides the most direct control over coverage and layer thickness and is often recommended for beginners, or when using pastes that are particularly viscous (thick) and may not spread easily under pressure alone. Some thermal pastes, like Fehonda's TR50L, include an application stencil and spreader to aid in this process, taking the guesswork out of applying the paste.

Research and testing often show that if the correct amount of thermal paste is used, the specific application pattern makes minimal difference to the final operating temperatures, provided the paste has good fluidity and spreads well under the cooler's pressure. However, the spreading or "buttered toast" method, especially when aided by tools like those provided with some Fehonda pastes, offers the advantage of visual confirmation of coverage before the heatsink is mounted, reducing the risk of dry spots or insufficient spread.. Regardless of the method chosen, once the cooler makes contact with the paste-applied IHS, it's important to avoid twisting or sliding the heatsink, as this can create air pockets and disrupt the even layer of paste. The debate over application methods is often more about ensuring complete and consistent coverage and avoiding air bubbles than about achieving minute temperature differences.

Subsection 6.4: The Pitfalls: Too Much vs. Too Little Paste and Their Consequences

Applying the correct amount of thermal paste is crucial; both extremes can lead to suboptimal cooling:

- Too Little Paste: If an insufficient amount of thermal paste is applied, it will not be able to fill all the microscopic air gaps between the IHS and the cooler base. This results in incomplete coverage, leaving air pockets that act as insulators, leading to poor heat transfer and significantly higher CPU/GPU temperatures. The component may then overheat and engage thermal throttling, reducing performance. In fact, applying too little paste can often result in worse thermal performance than applying slightly too much.

- Too Much Paste: Applying an excessive amount of thermal paste can also be problematic.

- Firstly, the excess paste will likely be squeezed out from the sides when the cooler is mounted, creating a mess on the CPU socket and surrounding motherboard components.

- Secondly, if the paste is electrically conductive (like metal-based or liquid metal pastes), this overflow can bridge electrical contacts and cause short circuits, potentially leading to permanent hardware damage. This is why using non-conductive pastes, such as those offered by Fehonda , is a safer option for many users.

- Thirdly, even if non-conductive, a very thick layer of thermal paste between the IHS and cooler can itself act as an insulator relative to an optimally thin layer or direct metal-to-metal contact. While paste is far more conductive than air, it is less conductive than the metals it is trying to bridge. An unnecessarily thick layer increases the thermal resistance path, hindering heat transfer and potentially leading to higher temperatures than an optimal application.

There is an optimal "Goldilocks zone" for thermal paste quantity. The goal is to use just enough to fill all the microscopic imperfections and create a continuous thermal path, forming the thinnest possible uniform layer.

Subsection 6.5: A Note on Electrically Conductive Pastes: Applying with Care

When working with metal-based or liquid metal thermal pastes, which can be electrically conductive, extreme caution is paramount. Any accidental spillage or spread of these pastes onto the CPU socket pins, motherboard circuitry, surface-mount components, or any other electrical contacts can lead to devastating short circuits and permanent damage to your hardware.

Furthermore, liquid metal pastes, typically containing gallium, have another critical consideration: gallium is highly corrosive to aluminum. This means liquid metal must not be used with heatsinks that have an aluminum base or any aluminum components that will come into direct contact with the paste. Using liquid metal on aluminum can cause the aluminum to degrade and weaken structurally over time, potentially damaging the cooler and compromising its mounting. Always verify heatsink material compatibility before considering liquid metal.

The use of electrically conductive pastes transforms the thermal paste application process from a relatively forgiving task into a high-stakes operation. The potential performance gain must be very carefully weighed against the significant risk of catastrophic hardware failure. This is why these types of pastes are generally recommended only for experienced PC builders and overclockers who understand the risks and are prepared to take meticulous precautions, such as masking off surrounding areas with non-conductive tape or applying conformal coating to nearby components. For users seeking high performance without this risk, advanced non-conductive pastes, such as Fehonda's TR50L with 14.8W/mK thermal conductivity, offer a compelling alternative.

Section 7: Longevity and Maintenance: When to Reapply Thermal Paste

Thermal paste is not a "set it and forget it" component indefinitely. Over time, its effectiveness can diminish, necessitating reapplication to maintain optimal cooling performance.

Subsection 7.1: How Long Does Thermal Paste Typically Last?

The lifespan of thermal paste can vary considerably based on its type, quality, and the operating conditions of the PC. General guidelines often suggest that thermal paste can last anywhere from 2 to 5 years, or 3 to 5 years, before a reapplication might be beneficial. Some manufacturers of high-quality thermal pastes may claim longer lifespans for their products, potentially 5 to 8 years or even more, based on their internal testing and formulation stability. For instance, Fehonda states that their TR50L paste's high-stability liquid compound lasts for years with no drying, cracking, or change in consistency, indicating a long service life. Intel suggests that, in most cases, users shouldn't need to reapply paste more than "once every few years" if no temperature issues are observed.

Certain types of paste are noted for their longevity. Carbon-based pastes, for example, are often cited for their "long life" and good stability, with diamond carbon variants also praised for "good stability". Premium brands like Thermal Grizzly often highlight "long-term stability" as a key feature for several of their high-performance products. Similarly, Fehonda emphasizes the "long service life" of their TR50L paste.

However, it's important to recognize that there's no single definitive answer for thermal paste lifespan due to the many variables involved. Manufacturer claims should generally be viewed as estimates under ideal conditions. Real-world longevity can often be shorter, and adopting a proactive approach to replacement (e.g., every 3-5 years, or sooner if issues arise) is generally better than waiting for significant thermal problems to manifest.

Subsection 7.2: Factors Affecting Lifespan: Paste Quality, System Usage, Heat Cycles

Several factors can influence how long thermal paste remains effective:

- Quality of Paste: Higher-quality thermal compounds, typically those with more stable base materials and advanced filler particles, are engineered to resist degradation better and generally last longer than cheaper, lower-quality options. For example, basic silicone-based pastes might degrade faster than those formulated with robust ceramic, metal, or advanced carbon fillers. Products like Fehonda's TR50L, which emphasize a "high-stability liquid compound," are designed for extended durability.

- System Workload and Operating Temperatures: Computers that are frequently subjected to heavy workloads—such as intense gaming, video rendering, scientific computations, or aggressive overclocking—generate more heat and experience more pronounced and frequent temperature fluctuations (heat cycles). These conditions can accelerate the degradation process of the thermal paste.

- Heat Cycling (The "Pump-Out" Effect): As a PC powers on and off, or transitions between idle and load states, the CPU and heatsink heat up and cool down. These components, being made of different materials, expand and contract at slightly different rates. Over a large number of these thermal cycles, this differential expansion and contraction can physically squeeze or "pump out" the thermal paste from the interface between the IHS and the cooler base. This gradually reduces the amount of paste in the critical contact area, diminishing its effectiveness.

- Drying Out and Component Separation: Over time, and particularly when exposed to sustained high temperatures, the liquid components (the matrix or binder) in some thermal pastes can evaporate or dry out. This causes the paste to become hard, brittle, or crumbly, losing its viscosity and its ability to effectively fill the microscopic gaps. Fehonda's TR50L is specifically mentioned to resist drying and cracking over its service life. In some cases, the polymer matrix and the filler particles can separate, leading to inconsistent thermal conductivity across the interface.

- Environmental Factors: External conditions such as high ambient humidity or significant dust accumulation within the PC case can also contribute to the faster degradation of thermal paste.

- Mounting Pressure: The pressure applied by the CPU cooler's mounting mechanism can also play a role in the longevity and stability of the thermal paste layer.

Thermal paste degradation is an inevitable process involving both physical changes (like pump-out) and chemical changes (like drying or separation) driven by the demanding operational environment within a PC. It's not a static component; it is actively performing its function and, in doing so, gradually wears out.

Subsection 7.3: Signs It's Time for a Refresh: Rising Temperatures and Performance Dips

Rather than relying solely on a fixed time schedule, it's crucial to be observant of your system's behavior, as this can provide direct indicators that your thermal paste may be losing its effectiveness:

- Increased CPU/GPU Temperatures: The most common sign is a noticeable and consistent increase in your CPU or GPU operating temperatures, especially at idle or under similar workloads compared to when the paste was fresh. This is particularly indicative if you've already ruled out other causes like dust buildup in fans and heatsinks.

- Performance Degradation: If your CPU or GPU begins to thermal throttle more frequently than before, you might experience stutters in games, lower frame rates, or slower performance in demanding applications. This can be a direct result of the components running hotter due to inefficient heat transfer.

- Unusual Fan Noise: Computer fans, particularly the CPU and GPU cooler fans, may start running faster and louder than normal. This happens as the system tries to compensate for higher component temperatures by increasing airflow.

- System Instability: In more severe cases of overheating due to degraded thermal paste, your computer might experience unexpected shutdowns or reboots, especially when under heavy load. This is often a built-in protective measure to prevent permanent damage from critical temperatures.

- Age of Application: As a proactive measure, if it has been several years (e.g., the commonly cited 3-5 year mark, or in line with manufacturer claims like Fehonda's "lasts for years" for TR50L ) since the thermal paste was last applied, it's wise to consider a reapplication even if overt symptoms haven't appeared yet.

- Crucial Reminder: Cooler Removal: It cannot be stressed enough: anytime the CPU cooler (or GPU cooler, if you're servicing a graphics card) is removed from the processor for any reason (e.g., cleaning, component upgrade, troubleshooting), the old thermal paste must be thoroughly cleaned off, and a fresh layer applied. Attempting to reuse the old, disturbed layer of paste is strongly discouraged, as it can lead to uneven coverage, trapped air bubbles, and significantly reduced thermal performance.

Monitoring your system's thermal behavior and performance is key to identifying thermal paste degradation. These observations can serve as an early warning system, prompting maintenance before a scheduled interval might otherwise suggest.

Subsection 7.4: Understanding Thermal Paste Degradation (Recap)

To reiterate, thermal paste degrades over time through several primary mechanisms:

- Drying out: The volatile liquid components within the paste's matrix can evaporate over time, especially under prolonged exposure to heat. This causes the paste to lose its pliability, becoming hard, dry, or crumbly. A dried-out paste can no longer effectively conform to surface imperfections or fill gaps. Pastes like Fehonda TR50L are formulated to resist this drying process.

- Pump-out effect: As mentioned earlier, the cyclical expansion and contraction of the CPU/IHS and the heatsink due to temperature changes can physically squeeze the paste out from between the two surfaces over many power cycles. This reduces the amount of TIM at the critical interface.

- Component separation: In some paste formulations, the thermally conductive filler particles and the liquid polymer matrix can separate from each other over time or under high temperatures. This leads to an inconsistent mixture that no longer provides uniform thermal conductivity. High-stability compounds, such as Fehonda's TR50L, aim to minimize such changes in consistency.

All these degradation pathways result in a reduced ability of the thermal paste to perform its primary function: efficiently bridging the thermal gap and conducting heat away from the processor. The physical and chemical nature of thermal paste means its degradation is multifaceted. This complexity is why high-quality pastes often emphasize their long-term stability and resistance to these various stressors.

Section 8: Conclusion: Maximizing Your PC's Health with Proper Thermal Management

Thermal paste, though a small and often inexpensive part of a PC build, plays an undeniably critical role in the overall health, performance, and longevity of your computer's core components.

Subsection 8.1: Recap: The Critical, Often Underestimated, Role of Thermal Paste

Throughout this guide, we've explored how thermal paste serves as an essential thermal interface material. Its primary function is to fill the microscopic imperfections and air gaps that exist between a heat-generating component like a CPU or GPU and its cooling solution. By displacing air (a poor thermal conductor) with a material of significantly higher thermal conductivity, thermal paste creates an efficient pathway for heat to travel from the processor to the heatsink. This process is vital for preventing overheating, ensuring that components can operate at their optimal performance levels without throttling, and ultimately prolonging their operational lifespan. Its ability to bridge these invisible gaps is key to unlocking the full cooling potential of the entire thermal management system.

Subsection 8.2: Final Tips for a Cool and Efficient System

To ensure your PC remains cool, stable, and performs at its best, keep these final tips regarding thermal paste and overall thermal management in mind:

- Choose Wisely: Select a thermal paste type that aligns with your specific needs, PC build (e.g., office PC, gaming rig, overclocked system), budget, and your comfort level with application (especially considering electrical conductivity risks). Consider reputable brands such as Fehonda, which offer a range of products like the TR50L series or their 8.5W/mK paste, catering to different needs with features like high thermal conductivity, non-conductivity, and ease of application tools.

- Prepare Thoroughly: Always meticulously clean the surfaces of the CPU/GPU IHS and the heatsink base of any old paste and contaminants before applying a new layer.

- Apply Correctly: Use the appropriate amount of thermal paste—generally a pea-sized dot for most CPUs. The goal is a thin, even layer that provides complete coverage without excessive squeeze-out. Utilize any included application tools, like stencils or spreaders that come with some Fehonda pastes, for easier and more precise application.

- Handle with Care: If using an electrically conductive paste (metal-based or liquid metal), exercise extreme caution during application to prevent spills that could short-circuit and damage components. Opting for a high-performance non-conductive paste can mitigate this risk.

- Monitor and Maintain: Keep an eye on your system's operating temperatures and performance. Be prepared to reapply thermal paste every few years, or sooner if you observe signs of degradation like consistently rising temperatures or performance dips, keeping in mind the expected lifespan and stability features of your chosen paste (e.g., Fehonda TR50L's long service life ).

- Reapply After Removal: Critically, always clean off the old paste and apply a fresh layer every single time you remove and reinstall the CPU cooler for any reason.

- Holistic Cooling: Remember that effective thermal management is a comprehensive effort. Thermal paste works in conjunction with a capable CPU cooler, good overall case airflow (intake and exhaust fans), and regular cleaning to keep dust accumulation at bay.

By understanding how thermal paste works and adhering to best practices for its selection, application, and maintenance, you can significantly contribute to a healthier, faster, and more reliable computing experience.