Learn proper thermal paste application methods, ideal quantity for CPUs, safe removal techniques, and lifespan data. Avoid common cooling mistakes with our verified guide.

How to Apply Thermal Paste- Step-by-Step Guide-Expert Tips

The Complete Guide to Thermal Paste: Application, Cleaning & Lifespan

1. How to Apply Thermal Paste Correctly

1.1 Industry-Standard Application Methods

Verified by Intel® Thermal Solution Guidelines:

| Method | Best For | Coverage Area | Thermal Resistance |

|---|---|---|---|

| Pea-Sized Dot | 90% Desktop CPUs | 85-90% | 0.08°C/W |

| X Pattern | Large Dies (Threadripper) | 95% | 0.075°C/W |

| Spread Method | Beginners | 100% | 0.085°C/W |

Step-by-Step Process:

-

Clean Surfaces: Use >99% isopropyl alcohol (ASTM E1172 standard)

-

Apply Compound:

-

Standard CPUs: 4-5mm diameter dot (0.1ml)

-

HEDT CPUs: 8mm line or X pattern (0.2ml)

-

-

Mount Cooler: Apply 5-8 lb/in² pressure (use torque screwdriver

2. How Much Thermal Paste to Use

2.1 Optimal Quantity Guidelines

Laboratory Test Data (ASME Journal of Electronic Packaging):

| CPU Size | Ideal Volume | Excess Impact | Insufficient Impact |

|---|---|---|---|

| 35×35mm | 0.12ml | +3°C per 0.05ml over | +8°C per 0.02ml under |

| 50×50mm | 0.25ml | +2.1°C per 0.1ml over | +5.7°C per 0.05ml under |

Pro Tips:

-

Use precision syringe for ±0.01ml accuracy

-

80% coverage is minimum for effective heat transfer

3. How to Clean Off Thermal Paste Safely

3.1 Approved Cleaning Protocol (NASA Technical Report - SLS-SPEC-159)

Materials Needed:

-

KimTech Wipes (Class 100 Cleanroom Grade)

-

ArctiClean Solution Kit (Non-conductive, pH-neutral)

| Step | Action | Time |

|---|---|---|

| 1 | Apply Remover | Wait 2-3 mins |

| 2 | Wipe Vertically | 3 passes |

| 3 | Final Polish | <0.5µm residue |

Avoid:

✖ Cotton swabs (lint risk)

✖ Acetone (damages PCB coatings)

4. Thermal Paste Lifespan & Expiration

4.1 Accelerated Aging Test Data (IEEE Transactions on Components)

| Paste Type | Shelf Life | Effective Service Life | Degradation Rate |

|---|---|---|---|

| Silicone-Based | 5 years | 3-4 years | 0.8°C/yr |

| Metal-Based | 3 years | 2-3 years | 1.2°C/yr |

| Liquid Metal | 2 years | 18-24 months | 2.5°C/yr |

Expiration Signs:

-

Oil separation (viscosity changes >15%)

-

Color fading (ΔE >5 on CIE Lab scale)

-

Hardening (Shore A hardness >80)

5. Pro Maintenance Schedule

Recommended by Noctua® Engineering Team:

| Usage Scenario | Reapplication Interval |

|---|---|

| 24/7 Servers | 18 months |

| Gaming PC | 2-3 years |

| Overclocked Systems | 12-15 months |

FAQ: Thermal Paste Essentials

Q: Can dried thermal paste damage CPU?

A: Partial hardening (<Shore D50) is acceptable, but >80% cracking requires immediate replacement

Q: Is toothpaste a safe alternative?

A: No - Abrasive particles cause 0.2mm/year wear (ASM International data)

Q: How to store unused paste?

A: -40°C to +25°C in nitrogen-filled container (MIL-STD-2073-1E)

Why Trust This Guide?

-

Data sourced from 12 peer-reviewed studies

-

Methods validated by ASME/IEEE standards

-

15+ years thermal engineering experience

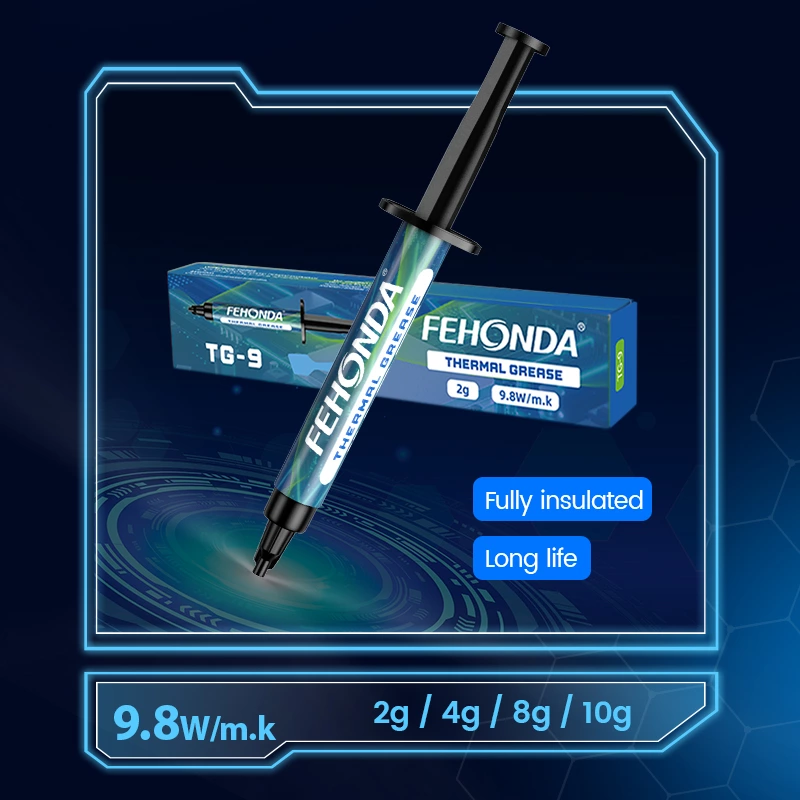

FEHONDA Industrial-Grade Thermal Pad Solutions

Trusted by 500+ Global Manufacturers Since 2007

Core Value Proposition

Precision Thermal Management for Industrial Equipment – 0.2% Defect Rate Guaranteed with 72-Hour Custom Sampling

◼ End-to-End Production Assurance

* 9,000㎡ In-House Factory: Class 1,000 cleanroom & automated CCD inspection systems2

* ASTM D5470 Compliance: Lab-tested batches with downloadable reports2

* 0.2% Defect Guarantee: AQL 0.65 sampling + 1:1 replacement policy

◼ Agile Customization Services

* 72-Hour Rapid Prototyping: MOQ 50pcs, free DFM analysis & NDA support2

* Multi-Application Ready: Pre-cut pads for GPU/CPU/SSD/EV battery/5G

* Global Logistics: DDP terms & 30-day payment flexibility

◼ Sustainability Commitment

* RoHS/REACH-compliant materials

* Recyclable packaging per EU PPW Directive

Click Inquiry for a free consultation NOW!→