Part 1: The Heat of the Matter: Understanding Why Your SSD Gets Hot

Modern Solid State Drives (SSDs), especially NVMe M.2 drives, can generate significant heat, which can impact their performance and lifespan.

Part 1: The Heat of the Matter: Understanding Why Your SSD Gets Hot

Modern Solid State Drives (SSDs), especially NVMe M.2 drives, can generate significant heat, which can impact their performance and lifespan.

The "Hot Pockets" Inside: Heat Generation from SSD Controllers and NAND Flash The SSD controller, akin to a mini-CPU managing all data operations, is a primary heat source. The faster it operates, the more heat it generates. NAND flash memory operations (reading, writing, erasing) involve electrical currents and high-frequency switching transistors, which inherently produce heat. The electron injection during writes is particularly prone to generating significant heat. Even the NVMe port itself can get hot, adding to the overall SSD temperature. Heat is a byproduct of the very processes that make SSDs fast; it's a characteristic to be managed.

The quest for speed dictates component choice and density, which in turn dictates thermal output. The evolution from slower SATA SSDs to high-speed NVMe M.2 drives has fundamentally changed the thermal landscape for consumer storage. User demand and technological advancements drive faster storage speeds. Faster speeds necessitate more powerful controllers and quicker NAND operations, which generate more heat. The M.2 form factor, favored for these high-speed drives due to its compactness, offers less surface area for heat dissipation and is often located in airflow-restricted areas. Thus, the very features that make modern SSDs desirable (speed, compact size) are the primary drivers of their increased thermal challenges. As SSDs continue to get faster and potentially denser, the need for effective cooling solutions like thermal pads will only grow.

NVMe M.2 SSDs: Compact Design, Concentrated Heat NVMe M.2 SSDs, while offering incredible speed, come in a small form factor. This means heat-generating components are densely packed with less surface area for natural heat dissipation. Many M.2 slots, especially in laptops or compact desktops, suffer from restricted airflow, exacerbating the issue. This physical design links modern high-performance SSDs directly to their thermal challenges.

The Impact of Heavy Workloads on SSD Temperature Tasks such as large file transfers, gaming, video editing, and sustained read/write operations significantly increase electrical activity within the SSD, leading to higher temperatures. Random read/write operations, particularly random writes, are the most demanding and heat-generating due to the intensive work by the controller and NAND. SSDs also tend to get hotter as they fill up (e.g., beyond 60%) due to background processes like garbage collection, which adds to the controller's load. Not just the SSD's design, but also how it's used, dictates its thermal load.

An SSD's internal "housekeeping" tasks (like wear-leveling, garbage collection, TRIM) intensify as the drive fills up, adding a "hidden" thermal load. SSDs employ complex algorithms to manage data and maintain performance/longevity. These processes involve internal data movement, which are essentially read/write operations handled by the controller and NAND. As an SSD fills, the number of free blocks decreases, making these background tasks more intensive and frequent, leading to more heat generation. Therefore, an SSD that appears "idle" but is nearly full might run hotter than expected, or an SSD under use might get hotter than when it was emptier due to this increased background activity. Thermal management is crucial not just for peak load scenarios but for overall drive health.

Part 2: The Perils of an Overheating SSD

Unmanaged heat in SSDs can lead to several negative consequences.

Thermal Throttling: When Your SSD Slows Down to Cool Down Thermal throttling is a built-in safety mechanism in SSDs that reduces their performance (and thus heat generation) when temperatures exceed a certain threshold. This results in noticeable slowdowns, impacting user experience, especially during demanding tasks. M.2 SSDs are particularly susceptible due to their design. Overheating directly links to a tangible loss of the performance.

Thermal throttling isn't just a momentary dip in performance; it can create a negative feedback loop. When an SSD overheats during a demanding task, the controller initiates thermal throttling. Because the SSD is slower, the task now takes longer, keeping the SSD under load for extended periods. This can exacerbate heat issues or lead to heat build-up again once throttling eases. Users experience slowdowns and may misdiagnose the problem, leading to incorrect troubleshooting.

Long-Term Risks: Reduced Lifespan and Data Integrity Concerns Sustained high operating temperatures can accelerate the wear and tear on NAND flash memory cells, potentially shortening the overall lifespan of the SSD. Solidigm notes most of their SSDs operate best between 0°C and 70°C, with extreme temperatures shortening lifespan. Research from AKCP suggests even a 5°C increase can significantly reduce a drive's life expectancy. High temperatures can adversely affect the data retention capabilities of NAND flash, increasing the risk of data corruption or loss, especially in extreme cases, as heat accelerates the decay of electrical charges in flash cells. These issues undermine the reliability and value of the storage investment.

The "safe operating temperatures" advertised by manufacturers (often up to 70°C or higher) primarily refer to preventing immediate physical damage, not necessarily ensuring optimal long-term performance, data integrity, and lifespan. Operating consistently near the upper limit, even if "safe," can have detrimental effects over time. Studies indicate that prolonged exposure to the higher end of this "safe" range (e.g., consistently above 50°C-60°C) accelerates NAND wear. Thermal throttling often kicks in before the absolute maximum temperature is reached, implying that temperatures causing throttling are undesirable for sustained operation. The truly "optimal" temperature for longevity and consistent performance might be well below the advertised maximum. Using a thermal pad aims to keep the SSD in this cooler, more optimal range.

System Instability: Crashes and Errors Linked to SSD Heat Severe SSD overheating can contribute to system-wide problems such as freezes, Blue Screen of Death (BSOD) errors, and unexpected shutdowns or reboots. Its erratic behavior due to heat can impact the stability of the entire system, highlighting the importance of proactive cooling.

Part 3: Thermal Pads Explained: Your SSD's Cooling Companion

Thermal pads are a common and effective solution to SSD heat problems.

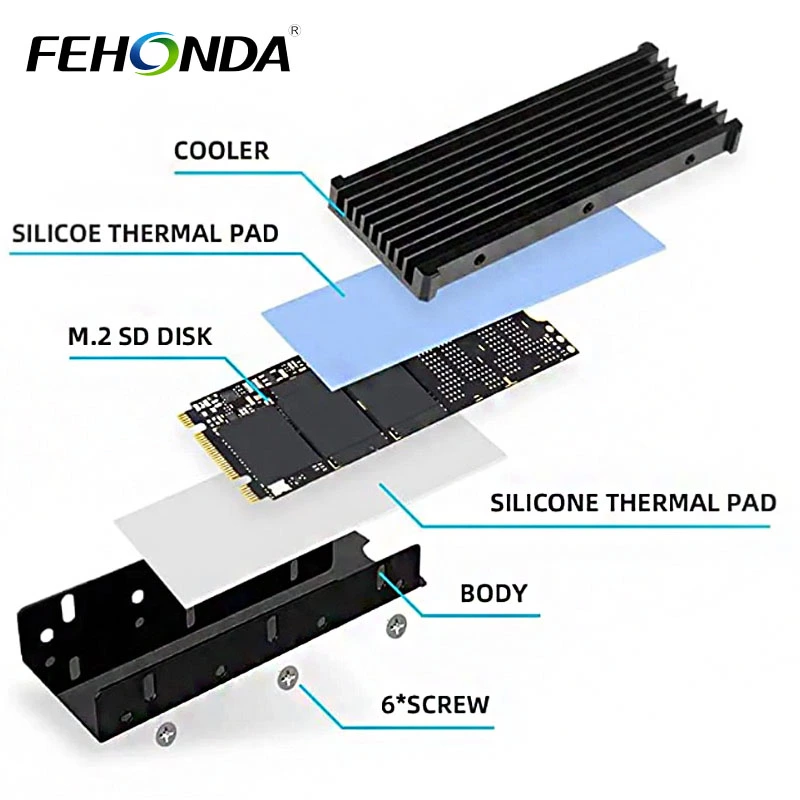

What Are Thermal Pads and How Do They Work? A thermal pad is a soft, conformable material (often silicone-based or graphite-based) designed to fill the microscopic air gaps between a heat-generating component (like an SSD controller or NAND chip) and a heat-dissipating surface (like a heatsink or the SSD enclosure itself). Air is a poor thermal conductor. Thermal pads replace these air gaps with a material that has significantly higher thermal conductivity, creating a more efficient pathway for heat to move away from the SSD components. This process is often referred to as improving "wet-out" or contact. They come in various thicknesses and materials to suit different gaps and applications.

The "softness" or "compliance" of a thermal pad (often described by Shore hardness) is critical for maximizing actual heat transfer. No machined surface is perfectly flat at a microscopic level; these imperfections create air pockets. A softer, more compliant pad will better "wet-out" or conform to these minute irregularities on both the heat source and the heatsink. Better conformance means fewer and smaller residual air pockets and a more intimate contact area for heat transfer. This directly reduces contact resistance, leading to more efficient heat transfer than a harder pad. Thus, softness is closely linked to thermal performance benefits.

Key Benefits of Using a Thermal Pad for Your SSD

The existence and variety of thermal pads (different materials, conductivities, thicknesses) reflect a maturing consumer understanding of thermal management. It's no longer just about applying any Thermal Interface Material (TIM); it's about choosing the right TIM for a specific application like an SSD. Early PC cooling often relied on generic thermal grease. Today’s market offers diverse TIMs: pads, greases, gels, phase change materials, and graphite sheets. Thermal pads themselves have different base materials, thermal conductivities (e.g., Fehonda's 8W, 12.8W, 15W/mK pads), and thicknesses. This specialization indicates manufacturers are responding to the demand for optimized solutions for specific components like SSDs, which have unique thermal characteristics. The availability of detailed specifications allows users to make more informed decisions, moving away from a one-size-fits-all approach.

Part 4: When Do You Need a Thermal Pad for Your SSD?

Here's how to determine if your SSD needs a thermal pad.

High-Performance Scenarios: Gaming, Video Editing, and Sustained Transfers SSDs used for demanding applications involving continuous, heavy data read/write operations are prime candidates for thermal pads. These activities work the controller and NAND harder, generating more heat.

Identifying the Need: Is Your NVMe M.2 SSD Overheating? Monitor SSD temperatures using software like CrystalDiskInfo, Samsung Magician, or HWMonitor. General temperature guidelines:

Systems with Limited Airflow or Existing Heatsink Solutions Laptops, compact Small Form Factor (SFF) PCs, or poorly ventilated cases can cause heat to easily build up around M.2 SSDs. If a motherboard comes with a dedicated M.2 heatsink/cover, it usually includes a thermal pad and should be used. If not, or if the stock solution is inadequate, an aftermarket thermal pad (and potentially heatsink) is beneficial.

The physical location of an M.2 SSD on a motherboard (e.g., near a hot GPU or in an area with poor airflow) can impact its operating temperature as much as its own workload. SSDs can be affected by heat generated by nearby components. Poor ventilation within a PC case traps heat around the SSD. M.2 slots are often located in areas that may not receive direct airflow. Consequently, an SSD might run hotter due to its environment. Users building new systems or choosing motherboards should proactively consider M.2 slot placement and available cooling options. Thermal pads become a tool to mitigate both self-generated and environmental heat.

While SSDs have internal thermal protection (throttling), relying solely on it is a reactive approach that sacrifices performance. The decision to use a thermal pad represents a user's shift towards proactive thermal management, prioritizing sustained performance and longevity. SSDs will thermally throttle to prevent overheating damage, which by definition means reduced performance. Choosing to install a thermal pad is a conscious decision to improve the thermal environment beyond the SSD's default state. This active intervention aims to keep temperatures below the throttling threshold, thereby maintaining higher, more consistent performance and potentially extending lifespan by reducing thermal stress.

Table 1: SSD Temperature & Action Guide

| SSD Type | Load Condition | General/Acceptable Temp Range (°C) | Concern Temp Range (°C) | Recommended Action |

|---|---|---|---|---|

| SATA SSD | Idle | 30-40 | >45 Consistently | Monitor, Improve Airflow |

| SATA SSD | Light Load | 35-45 | >50 Consistently | Monitor, Improve Airflow |

| SATA SSD | Heavy Load | 45-55 | >60 | Improve Airflow, Consider Pad |

| SATA SSD | Sustained Heavy Load | 50-60 | >65 | Pad/Heatsink Essential, Improve Airflow |

| NVMe M.2 SSD | Idle | 35-45 | >50 Consistently | Monitor, Check Mobo Heatsink, Consider Pad |

| NVMe M.2 SSD | Light Load | 40-50 | >55 Consistently | Monitor, Consider Pad |

| NVMe M.2 SSD | Heavy Load | 50-70 | >70 | Thermal Pad &or Heatsink Highly Recommended, Optimize Airflow |

| NVMe M.2 SSD | Sustained Heavy Load | 60-80 (Throttling Likely) | >75 Consistently | Quality Pad & Heatsink Essential, Ensure Good Airflow |

Part 5: Fehonda Thermal Pads: Engineered for Optimal SSD Cooling

Fehonda offers solutions for SSD thermal challenges.

Why Fehonda? Quality, Performance, and Reliability Fehonda is a thermal material solutions provider committed to personalized solutions with wide application in various fields. Positive reviews and testing from tech reviewers like PRO Hi-Tech and Vik-Off support their credibility; for instance, in some reviews, Fehonda pads "ranked second in the test of 20 thermal pads, but ranked First in non-conductive thermal pads". Fehonda emphasizes quality materials and manufacturing processes.

Fehonda's Range of SSD Cooling Solutions:

High-Conductivity Silicone Thermal Pads (e.g., 8W/mK, 12.8W/mK, 15W/mK)

Fehonda's emphasis on non-conductive thermal pads, even while achieving high thermal conductivities, and the positive reception of this feature, suggests a strategy to appeal to a broader, safety-conscious consumer base. Electrical conductivity in TIMs can pose a short-circuit risk. Fehonda consistently highlights the non-conductive nature and high breakdown voltage of their pads and putties. Reviewers praise this non-conductivity alongside good thermal performance. This focus on safety plus performance makes their products attractive to a wider range of users, positioning Fehonda as a reliable and safe performance brand.

Fehonda LTP81 Liquid Thermal Putty: A Flexible High-Performer (18W/mK)

Fehonda's offering of both precision-thickness high-performance thermal pads and highly conformable thermal putty (LTP81) indicates an understanding of diverse and evolving cooling needs. Standard M.2 SSDs and heatsinks often have relatively predictable gap sizes where specific thickness pads are ideal. However, some cooling solutions or manufacturing tolerances can lead to uneven gaps where fixed-thickness pads aren't optimal. Thermal putty like Fehonda LTP81 is designed to address these variable gaps. Offering both product types allows Fehonda to cater to a wider spectrum of applications, showing an adaptation to the increasing complexity of thermal management in modern electronics.

Commitment to Quality: Fehonda Certifications (ISO, RoHS, UL, CE) Certifications like ISO 9001, ISO 14001, ISO 45001, RoHS, UL, and CE are mentioned across Fehonda's product listings, signifying adherence to quality, safety, and environmental standards.

Table 2: Fehonda SSD Cooling Solutions Selector

| Fehonda Product Series | Thermal Conductivity (W/mK) | Typical SSD Application | Key Advantages | Thickness Range (Pads) / Gap Filling (Putty) (mm) | Electrically Non-Conductive |

|---|---|---|---|---|---|

| Fehonda Silicone Thermal Pad 15W | 15 | High-End NVMe (PCIe 4.0/5.0) | Maximum Thermal Performance | 0.5 - 3.0 (common SSD thicknesses) | Yes |

| Fehonda Silicone Thermal Pad 12.8W | 12.8 | Mainstream NVMe, High-Perf SATA M.2 | Balanced Performance | 0.5 - 3.0 (common SSD thicknesses) | Yes |

| Fehonda Silicone Thermal Pad 8W | 8 | SATA M.2, Light-Load NVMe | Cost-Effective | 0.5 - 3.0 (common SSD thicknesses) | Yes |

| Fehonda LTP81 Liquid Thermal Putty | 18 | NVMe/SATA M.2 with uneven gaps or variable heights, multi-component cooling | Flexible Gap Filling | 0.3 - 3.0 | Yes |

Part 6: Practical Guide: Choosing and Installing Your Fehonda Thermal Pad

Here are actionable steps for users who need a Fehonda thermal pad.

Matching Pad to Your SSD: Thickness and Conductivity Considerations

The most common failure point for thermal pad effectiveness is not the pad itself, but incorrect thickness selection or improper installation (e.g., protective film not removed, insufficient pressure, air bubbles). If a pad is too thick, it increases thermal resistance or prevents proper heatsink mounting. If too thin, it fails to fill the gap. Contamination or leaving protective films on will impede heat transfer. Uneven pressure during heatsink installation can lead to poor contact. Even with a high-quality Fehonda pad, performance can be subpar if these steps aren't followed.

Fehonda's offering of thermal pads in small thickness increments (e.g., 0.25mm steps) and multiple sizes, alongside customization, addresses the critical need for precise gap filling. Optimal thermal transfer requires precise gap filling. Gaps vary due to SSD/heatsink design and manufacturing tolerances. Fine thickness increments allow users to select a pad closer to the actual gap, minimizing compression or air pockets. Various pre-cut sizes and custom cutting services reduce user effort and potential errors. This shows Fehonda understands practical TIM application challenges and aims to provide solutions optimized for correct installation.

Step-by-Step Installation for Peak Performance

A Note on Applying Fehonda LTP81 Thermal Putty (if relevant for SSDs): Putty application involves carefully applying and spreading the material to the desired thickness to cover heat sources, then mounting the heatsink. It's recommended to use gloves. It is a pad replacement for specific scenarios.

Part 7: Conclusion: Maximize Your SSD's Potential with Fehonda Thermal Management

Managing SSD heat is crucial for performance, lifespan, and stability. Thermal pads, particularly those from Fehonda, offer an effective solution. Key scenarios for using a Fehonda thermal pad include high-performance tasks, systems with limited airflow, and when existing cooling is inadequate.

By choosing Fehonda, users are taking a proactive approach to system health and performance, supported by a company offering specialized, quality-certified solutions. Purchasing and installing a Fehonda thermal pad is a step towards optimizing and protecting your SSD and, by extension, your entire system. Fehonda provides users with the tools to take control of their hardware's thermal destiny, ensuring they get the most out of their investment.

As SSD technology continues to advance in speed and density, the importance of effective thermal management will only grow. Fehonda's range of high-conductivity pads and innovative solutions like thermal putty show they are equipped to handle current and future thermal challenges. Choosing Fehonda is a smart move for both current needs and future upgrades, positioning them as a knowledgeable partner in PC thermal management.

To find the most suitable "cooling companion" for your electronic devices:

FEHONDA's new materials are used in a variety of applications around the world, providing effective solutions for thermal conductivity, shielding and more for products. Our sales and engineering support teams are ready to help you with any questions you may have, including quotations, product application support and product customization. Please submit your request via our custom service form to ensure a faster response.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details