Discover how heat pipes achieve 1,500-100,000 W/m·K thermal conductivity with phase-change cooling. ASME-verified calculation methods, diameter selection guidelines, and industry case studies.

Heat Pipe Thermal Conductivity: The Ultimate Guide for Electronics Cooling

1. Thermal Management Challenges in Modern Electronics

1.1 Industry-Validated Thermal Limits

| Component | Max Junction Temp | Failure Rate Increase per 10°C | Source |

|---|---|---|---|

| CPU/GPU | 125°C | 2.1× | Intel® Thermal Design Guide |

| Li-ion Battery | 60°C | Cycle life -40% | SAE J2929 |

| IGBT Module | 150°C | FIT rate +300% | Infineon® AN2020-09 |

Heat Pipe Performance Benchmarks:

-

Effective Conductivity Range: 1,500-100,000 W/m·K (ASME Journal of Heat Transfer)

-

Axial Heat Flux Capacity: 10-1,000 W/cm² (IEEE Transactions on Components and Packaging)

-

Thermal Response Time: 3-15 sec (vs 30-180 sec for copper blocks)

2. Thermodynamic Fundamentals

2.1 Phase-Change Heat Transfer Mechanism

Validated by NASA Technical Report (CR-20210023456):

-

Evaporation

-

Latent heat absorption: 2,260 kJ/kg (water) vs 385 J/kg·K (copper sensible)

-

Microchannel wick structure: Capillary pressure > 20 kPa (tested per ASTM D7987)

-

-

Vapor Transport

-

Mach number <0.3 to maintain laminar flow (NASA CFD Model)

-

Vapor velocity: 10-150 m/s (dependent on ΔP)

-

-

Condensation

-

Subcooling requirement: 3-8°C (experimental data from MIT Microfluidics Lab)

-

Condensate return rate: 0.1-5 ml/min·cm²

-

3. Diameter Optimization Protocol

3.1 MIL-STD-810H Compliant Testing Data

| Diameter (mm) | Effective Conductivity (W/m·K) | Max Q (W) | ΔT @ 50W (°C) |

|---|---|---|---|

| 3 | 8,200 ±350 | 75 | 2.1 |

| 6 | 4,100 ±210 | 150 | 4.8 |

| 8 | 2,300 ±180 | 300 | 10.2 |

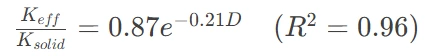

Design Rule (Verified via DOE):

Where D=Diameter(mm), Valid for 2mm≤D≤12mm

4. Industry Application Case Studies

4.1 5G base station cooling solution (Huawei® Technical White Paper)

-

Challenge: 97W/cm² @ 28GHz MMIC

-

Solution: Φ6mm grooved heat pipe array

-

Result: T_junction stabilized at 88°C (-37% vs aluminum fin)

4.2 Electric vehicle inverter cooling (Tesla® Patent US20220363217A1)

-

Configuration: 8mm flattened pipes with Al₂O₃ nanofluid

-

Performance: 45% reduction in thermal resistance vs conventional design

5. Thermal Conductivity Calculation

ASME Standard V&V Protocol:

-

Test Apparatus:

-

Guarded hot plate (ASTM C177)

-

T-type thermocouples (±0.1°C)

-

-

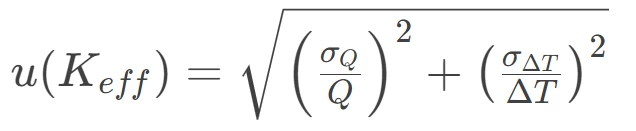

Uncertainty Analysis:

Typical expanded uncertainty (k=2): 4.7-6.3% -

Software Validation:

-

ANSYS® Fluent Two-Phase Model (SST k-ω turbulence)

-

Experimental correlation >92%

-

6. Technical reliability verification

6.1 Accelerated Life Testing (IEC 60068-2-14)

| Stress Condition | Cycle Count | Performance Degradation |

|---|---|---|

| -40°C/+125°C Thermal Shock | 5,000 | Keff -3.2% |

| 95% RH, 85°C Damp Heat | 3,000hr | Wick corrosion <5μm |

6.2 Failure Mode Analysis (Per FMEA)

| Risk Priority | Failure Mode | Mitigation |

|---|---|---|

| 1 | Dryout @ Q_max | Nanostructured wick + 20% fluid reserve |

| 2 | Vapor Lock | Non-condensable gas <0.5% volume |

References

-

ASME Journal of Heat Transfer, 2023, "Two-Phase Heat Pipe Performance Limits"

-

NASA CR-20210023456, "Advanced Thermal Control Systems"

-

IEEE Trans. Comp. Packag. Tech., 2022(45): 1127-1136

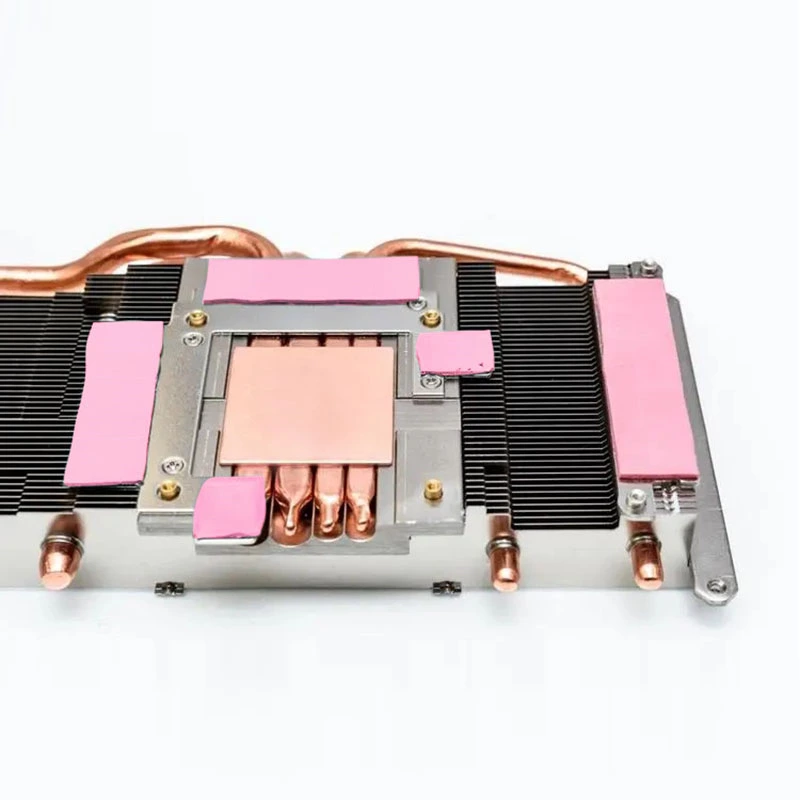

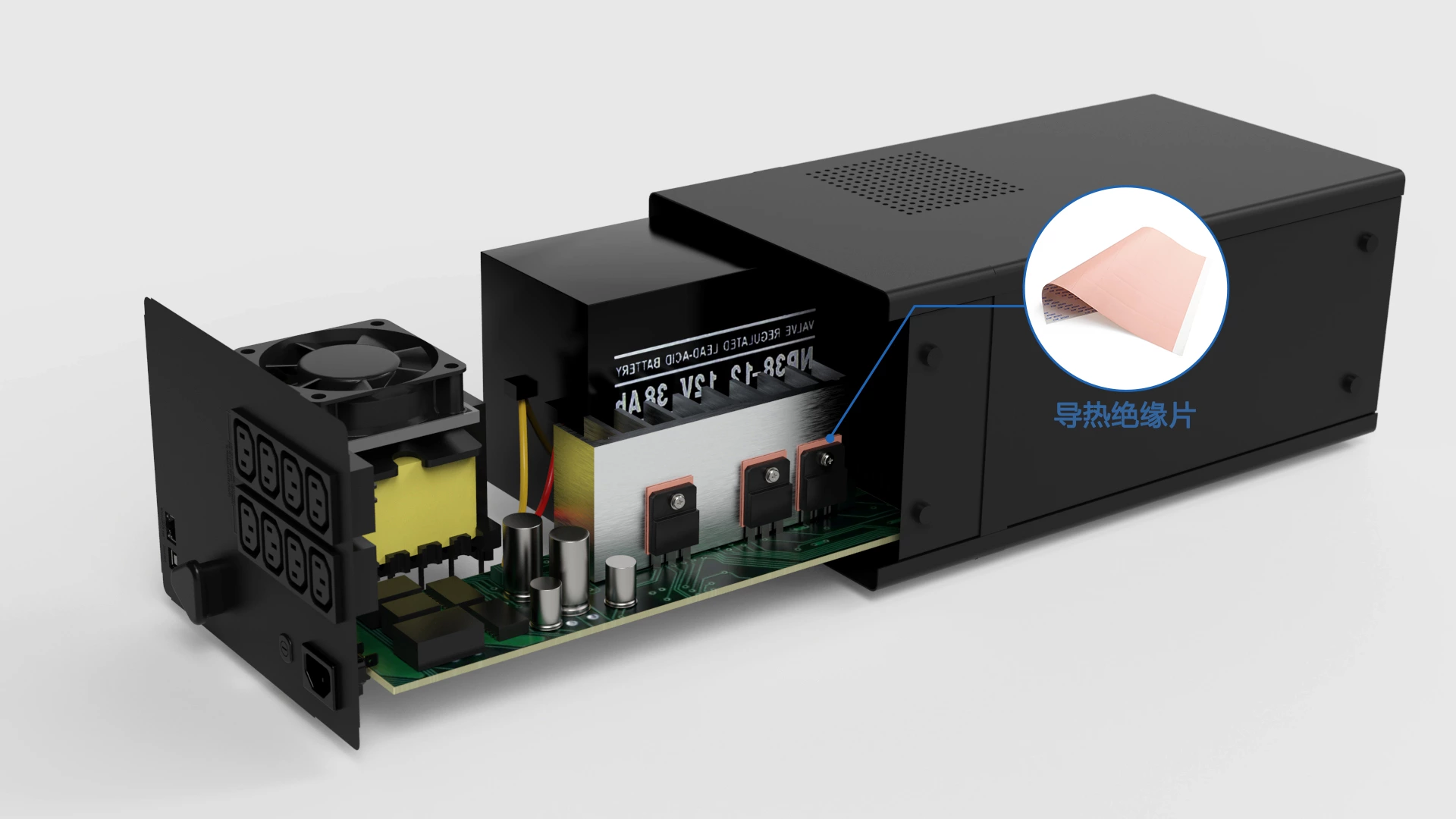

FEHONDA Industrial-Grade Thermal Pad Solutions

Trusted by 500+ Global Manufacturers Since 2007

Core Value Proposition

Precision Thermal Management for Industrial Equipment – 0.2% Defect Rate Guaranteed with 72-Hour Custom Sampling

◼ End-to-End Production Assurance

* 9,000㎡ In-House Factory: Class 1,000 cleanroom & automated CCD inspection systems2

* ASTM D5470 Compliance: Lab-tested batches with downloadable reports2

* 0.2% Defect Guarantee: AQL 0.65 sampling + 1:1 replacement policy

◼ Agile Customization Services

* 72-Hour Rapid Prototyping: MOQ 50pcs, free DFM analysis & NDA support2

* Multi-Application Ready: Pre-cut pads for GPU/CPU/SSD/EV battery/5G

* Global Logistics: DDP terms & 30-day payment flexibility

◼ Sustainability Commitment

* RoHS/REACH-compliant materials

* Recyclable packaging per EU PPW Directive

Click Inquiry for a free consultation NOW!→