In the intricate world of modern electronics, managing heat is paramount. As components become more powerful and compact, the challenge of dissipating thermal energy effectively grows. This is where thermal pads play a critical, often underestimated, role. For anyone searching "wärmeleitpads kaufen" (buying thermal pads) or looking to enhance their system's cooling, this comprehensive guide will illuminate the path to making an informed decision, with a special focus on Fehonda's advanced thermal solutions.

The Ultimate Guide to Buying Thermal Pads Maximize Cooling & Performance

The Critical Role of Thermal Pads in Modern Electronics

What are thermal pads?

Thermal pads, also known as thermally conductive pads or thermal interface pads, are pre-formed, solid sheets of material, typically silicone-based. Their fundamental purpose is to bridge the microscopic air gaps that exist between a heat-generating component—such as a Central Processing Unit (CPU), Graphics Processing Unit (GPU), Video Random Access Memory (VRAM), or Solid State Drive (SSD)—and its corresponding heatsink or cooling assembly. Air is a notoriously poor conductor of heat, and these imperfections on component and heatsink surfaces can significantly impede efficient thermal transfer. Thermal pads serve as an alternative to thermal paste, proving particularly useful for bridging larger gaps or in applications where paste application might be less convenient or practical.

Why are they essential for performance and longevity?

Effective heat dissipation is not merely a luxury; it's a necessity for the optimal performance and extended lifespan of electronic components. When components overheat, they can suffer from performance throttling (slowing down to reduce heat output), system instability, unexpected crashes, and, in severe cases, permanent physical damage. By creating a more efficient thermal pathway, thermal pads enable heatsinks to draw heat away from sensitive components more effectively. This results in cooler operating temperatures, which in turn ensures more stable performance, allows components to operate at their peak potential for longer, and ultimately contributes to the longevity of the entire device.

The increasing power density observed in contemporary electronics, particularly in high-performance CPUs and GPUs, underscores the escalating importance of effective thermal management. This trend is not confined to high-end desktop systems; even compact devices like drones feature "small structure, concentrated heat," demanding sophisticated thermal solutions. Consequently, high-quality thermal pads are becoming more critical than ever, not just for overclocking enthusiasts but for ensuring the fundamental reliability and durability of a wide array of electronic devices. Users are increasingly moving beyond components that simply "work" to seeking those that deliver "optimal performance." This drive often leads them to explore aftermarket thermal solutions, as stock cooling might be adequate for basic operation but falls short for those desiring lower temperatures, quieter systems (as fans don't need to work as hard), or the extra thermal headroom required for overclocking. In this context, Fehonda thermal pads represent an upgrade, a pathway to unlocking enhanced performance and reliability.

Briefly introduce Fehonda

Fehonda (Feihongda Technology) stands as a leading provider of advanced electromagnetic shielding and thermal conductive material solutions, originating from China. With a steadfast commitment to quality, innovation, and providing personalized overall solutions, Fehonda has established itself as a trusted name in thermal management across diverse fields including communication, medical, security, military, power supply, lighting, mobile phone terminals, automotive electronics, and instrumentation.

Key Considerations When Buying Thermal Pads ("Wärmeleitpads Kaufen")

For individuals actively searching "wärmeleitpads kaufen" or "buying thermal pads," understanding the key characteristics of these materials is crucial for making an effective purchase. The German keyword implies a user already in the buying cycle, making this section pivotal in addressing their decision-making criteria with clear, actionable advice, and positioning Fehonda favorably against each.

A. Thermal Conductivity (W/mK): Decoding the Numbers for Optimal Heat Transfer

Thermal conductivity, often denoted by λ (lambda) or K, is a fundamental property that measures a material's ability to conduct heat. It is typically expressed in Watts per meter-Kelvin (W/mK). A higher W/mK value generally signifies better heat transfer capabilities. Common thermal pads on the market exhibit thermal conductivities ranging from 1W/mK to 16W/mK, with some high-performance options exceeding this. Fehonda offers an impressive range of thermal pads with conductivities including 8W/mK, 12.8W/mK, and 15W/mK, and is actively developing solutions in the 15−20W/mK range.

While a high W/mK value is desirable, it is important to understand that it is not the sole determinant of a thermal pad's real-world performance. Other factors, such as the pad's thickness, its ability to conform to surfaces (hardness/compressibility), and the resulting contact resistance at the interfaces, also play significant roles in overall thermal efficiency. Some manufacturers, like ARCTIC, even express caution about relying solely on published W/mK values, citing instances of potential inflation or manipulation, and instead emphasize holistic performance. Nevertheless, thermal conductivity remains a useful comparative metric when understood within the broader context of a pad's specifications. A general guideline for matching thermal conductivity to heat load is:

- Low power applications (≤5W/cm2): 3−6W/mK pads may suffice.

- Medium power applications (5−15W/cm2): 8−12W/mK pads are often recommended.

- Extreme power applications (>15W/cm2): 15−18W/mK or higher pads are preferable.

B. Thickness: Achieving Perfect Contact and Gap Filling

The thickness of a thermal pad is a critical parameter that must be carefully chosen to precisely fill the gap between the heat-generating component and the heatsink. An incorrectly sized pad can lead to suboptimal cooling: if too thin, it may not make adequate contact, leaving air pockets; if too thick, it can create excessive pressure on components, potentially causing damage or preventing the heatsink from mounting correctly.

Generally, thinner pads offer lower thermal resistance and thus better heat transfer, provided they can effectively bridge the gap. Thicker pads are necessary for larger or more uneven gaps. Typical thermal pad thicknesses range from 0.3mm to 10mm, with some specialized applications requiring even thicker pads. Fehonda distinguishes itself by offering a comprehensive range of thicknesses, from 0.5mm up to 3.0mm for its consumer-facing lines, and crucially, this includes precise 0.25mm increments such as 0.75mm,1.25mm,1.75mm, and 2.25mm. This level of granularity is a significant advantage, as many competitors often only provide 0.5mm steps. This precision allows users to achieve a truly optimized fit, addressing a common challenge where a 0.5mm pad might be too thin and a 1.0mm pad too thick.

C. Hardness & Compressibility (Shore Rating): Ensuring Optimal Conformability

The hardness of a thermal pad, often measured using the Shore durometer scale (e.g., Shore 00, Shore A, Shore C), indicates its firmness and resistance to compression. A lower Shore value typically corresponds to a softer, more compressible pad.

Softer pads are generally preferred because they can conform more readily to irregular surfaces and microscopic voids, ensuring more intimate contact between the component and the heatsink with less mounting pressure. This enhanced conformability is vital for maximizing the actual surface area available for heat transfer. Fehonda thermal pads are consistently described as "soft" and "flexible," with hardness ratings typically falling within the 20-45 Shore C or 30-55 Shore C range. Some Fehonda products are even characterized as "putty based pads," highlighting their exceptional ability to compress and mold to surfaces. While harder pads might offer greater durability in some scenarios, their reduced conformability can compromise thermal performance if surfaces are not perfectly flat.

D. Material Composition: The Science Behind Effective Heat Transfer

The material composition of a thermal pad dictates its thermal, mechanical, and electrical properties.

- Silicone-based pads are the most prevalent type, valued for their excellent flexibility, good thermal stability over a wide range of temperatures, and inherent electrical insulation properties. Fehonda's thermal pads are primarily crafted from high-quality silicone compounded with other Thermal Interface Materials (TIMs) to optimize performance.

- Non-silicone pads, often based on polyolefins or resins, are available for applications where silicone outgassing or oil bleed could be detrimental, such as in sensitive optical or medical devices.

- Fillers, such as ceramic particles or metal oxides, are incorporated into the base material (e.g., silicone) to enhance its thermal conductivity.

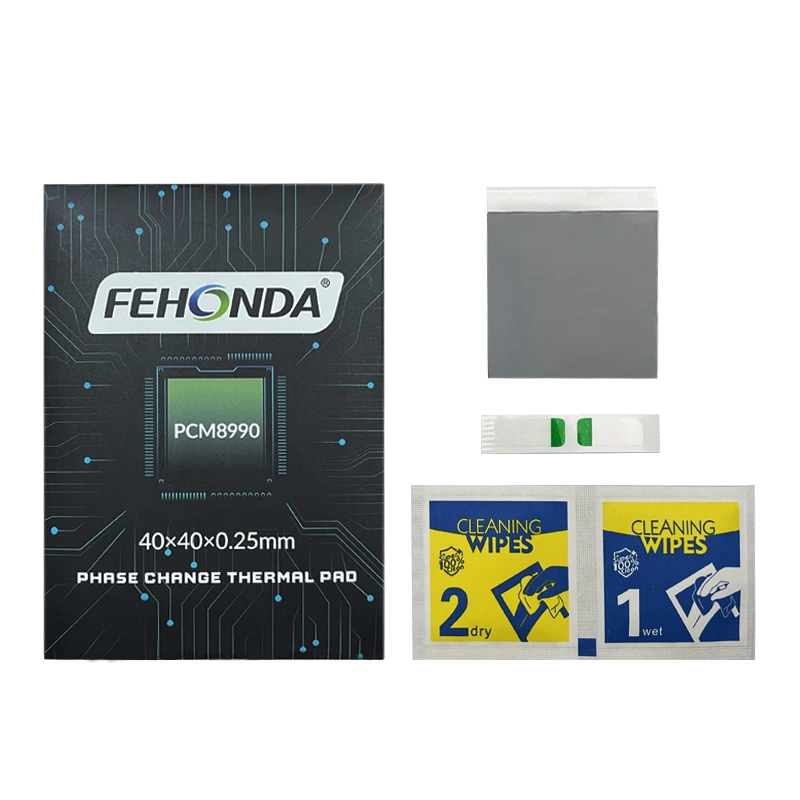

- Other specialized materials include graphite pads, known for high thermal conductivity in specific orientations, and Phase Change Materials (PCMs), which soften or melt at a specific temperature to achieve excellent surface wetting and minimal bond line thickness. Fehonda also offers phase change thermal pads, catering to advanced cooling needs.

E. Electrical Non-Conductivity: A Crucial Safety Feature

For the vast majority of consumer electronics applications, including cooling CPUs, GPUs, and other motherboard components, it is imperative to choose thermal pads that are electrically non-conductive. This is a critical safety feature, as an electrically conductive pad could cause short circuits if it inadvertently makes contact with exposed traces or components on the PCB.

Fehonda thermal pads are consistently highlighted as being electrically non-conductive. This characteristic is a significant selling point and a major factor in their positive reception by reviewers; notably, PRO Hi-Tech and Vik-Off reviews ranked Fehonda first among non-conductive pads in their comparative tests. The electrical insulation capability of a pad is often quantified by its breakdown voltage, with Fehonda pads typically rated at over 6−10KV/mm. This focus on non-conductivity provides users, especially those less experienced with PC building, with crucial peace of mind.

F. Size and Customization: Finding the Right Fit

Thermal pads are available in a variety of pre-cut sizes (e.g., 80mm×40mm, 85mm×45mm, 100mm×100mm, 120mm×20mm) and as larger sheets that can be easily cut to fit the specific dimensions of the components being cooled. The ease with which silicone-based pads can be cut to the required shape and size is a practical advantage. Fehonda offers pads in common standard sizes such as 85mm×45mm and 100mm×100mm, and also provides options for custom sizes, catering to diverse application needs.

Discover Fehonda Thermal Pads: Engineered for Excellence

Fehonda's approach to thermal pad design appears to center on delivering a balanced trifecta of high performance (evidenced by competitive W/mK ratings), paramount safety (through consistent electrical non-conductivity), and superior applicability (achieved via exceptional softness, flexibility, and uniquely precise thickness options). This strategy moves beyond merely chasing the highest thermal conductivity figures, which can sometimes result in pads that are too hard or less conformable for real-world scenarios. Instead, Fehonda emphasizes "Soft Custom" pads that excel in adapting to the imperfect surfaces commonly encountered in electronic assemblies.

A. Overview of Fehonda's Thermal Pad Product Lines

Fehonda offers several lines of thermal pads for the consumer market, primarily differentiated by their thermal conductivity ratings. These allow users to select a product that best matches their specific cooling requirements and budget:

- Fehonda 8W/mK Series: A solid choice for general-purpose cooling and applications with moderate heat loads.

- Fehonda 12.8W/mK Series: Offers enhanced thermal performance for more demanding applications, such as gaming PCs and workstations.

- Fehonda 15W/mK Series: Fehonda's premium offering for high-end cooling needs, suitable for overclocked systems and components generating substantial heat.

B. Detailed Specifications: The Fehonda Advantage

Fehonda thermal pads are characterized by a compelling set of specifications:

- High Thermal Conductivity: Ranging from 8W/mK to 15W/mK in readily available consumer lines, with some sources indicating capabilities up to 18W/mK and ongoing development towards 15−20W/mK products.

- Precise Thickness Options: A key differentiator is the availability of a wide array of thicknesses, typically from 0.5mm up to 3.0mm (with B2B options potentially reaching 10mm or more ). Crucially, this includes 0.25mm increments (0.75mm,1.25mm,1.75mm,2.25mm,2.75mm), allowing for an exceptionally precise fit that is often not available from competitors. This precision directly addresses the challenge of matching pad thickness to the often-varied gap heights found on complex PCBs, such as those in modern graphics cards.

- Optimal Hardness & Flexibility: Fehonda pads are engineered to be "soft" and "flexible," typically with Shore C hardness ratings between 20-45 or 30-55. This ensures excellent conformability to component surfaces, minimizing contact resistance and reducing stress on delicate parts.

- High-Quality Silicone & TIM Material: Constructed from durable, high-grade silicone and advanced Thermal Interface Materials (TIMs) to ensure consistent and reliable thermal performance.

- Superior Electrical Non-Conductivity: With a breakdown voltage exceeding 6−10KV/mm, Fehonda pads offer robust electrical insulation, safeguarding components against short circuits.

- Standard and Custom Sizes: Available in popular dimensions like 85mm×45mm and 100mm×100mm, with options for custom sizing to meet specific project needs.

C. Unique Selling Propositions (USPs) of Fehonda Pads

Beyond the core specifications, Fehonda pads offer several unique advantages:

- Exceptional Softness and Conformability: This leads to superior surface contact and more efficient heat transfer, particularly crucial on components with uneven surfaces or varying heights. Some pads are even described as "putty based," capable of being compressed significantly to fill gaps perfectly.

- Wide Temperature Tolerance: Fehonda pads are designed to operate reliably across a broad temperature spectrum, typically from −40∘C to +180∘C.

- Low Oil Penetration Rates: With oil penetration rates typically at ≤1%, these pads minimize the risk of silicone oil bleed, which can contaminate surrounding components and degrade performance over time.

- Durability and Reliability: Engineered for long-lasting performance, Fehonda pads maintain their thermal effectiveness over extended periods. For instance, their pads have undergone over 2000 hours of reliability testing.

- Excellent Mechanical Properties: Good tensile strength and elongation figures indicate robust physical characteristics.

- Consistent Density: Typically around 3.4−3.5±0.2g/cm3, contributing to their thermal properties.

D. Expert Endorsements & Reviews

The quality and performance of Fehonda thermal pads have been recognized by independent industry experts and reviewers. Tech channels like PRO Hi-Tech and Vik-Off have conducted comparative tests featuring Fehonda products, providing valuable third-party validation. A significant finding from these reviews is that Fehonda pads were ranked second overall in a comprehensive test of 20 thermal pads by PRO Hi-Tech, but notably secured the FIRST position among non-conductive thermal pads. This is a powerful testament to their safety and performance balance. Vik-Off also featured Fehonda 15W/mK pads in a live YouTube test. Russian-language reviews from these channels further indicate that Fehonda pads, particularly the 12.8W/mK variant, offer excellent price-to-performance, competing favorably with well-known brands like Gelid GP Ultimate/Extreme.

E. Complementary Fehonda Thermal Solutions

Fehonda's expertise in thermal management extends beyond just pads. They also offer:

- Fehonda Thermal Putty: Products like Fehonda LTP81 (18W/mK) and LTP65 are highly performant thermal putties. These are excellent for filling very uneven gaps or for components where a solid pad might not be ideal, offering a conformable, paste-like application that solidifies to provide effective thermal transfer.

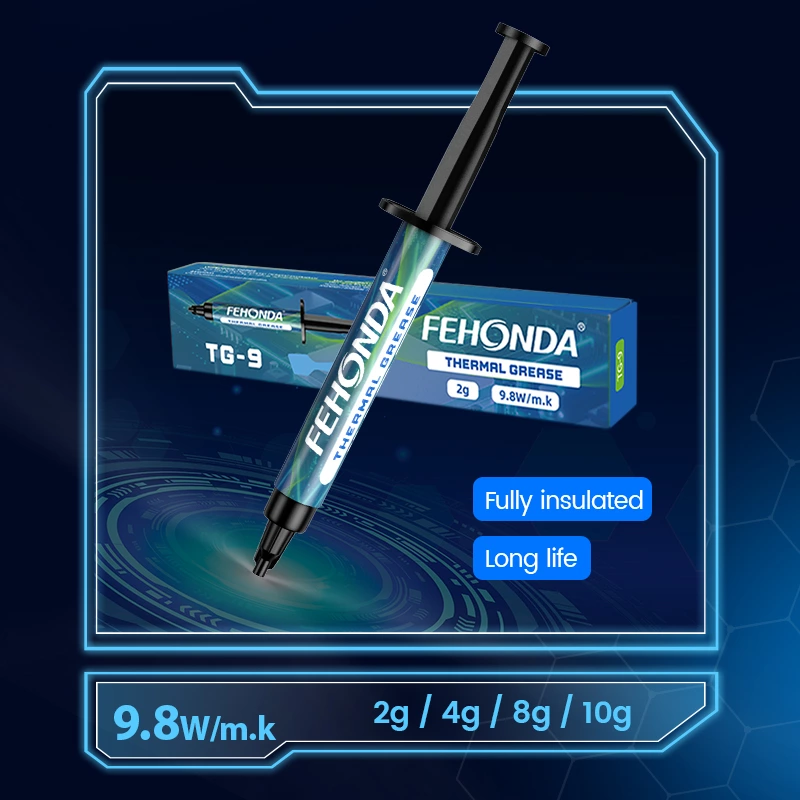

- Fehonda Thermal Grease/Paste: For applications requiring the thinnest possible bond line, such as direct die cooling of CPUs or GPUs, Fehonda provides thermal grease with a respectable 8.5W/mK thermal conductivity.

F. Commitment to Quality: Fehonda's Certifications

Fehonda's dedication to quality is underscored by its status as a national high-tech enterprise in China (Feihongda Technology) and its adherence to stringent international standards. The company holds numerous certifications, including ISO9001 (Quality Management), ISO14001 (Environmental Management), ISO45001 (Occupational Health and Safety), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), CE (Conformité Européenne), and SGS, ensuring their products meet rigorous quality, safety, and environmental benchmarks. Furthermore, Fehonda has made significant investments in research and development (R&D) and state-of-the-art production facilities, reflecting a deep commitment to innovation and manufacturing excellence.

Choosing the Right Fehonda Thermal Pad for Your Application

Selecting the appropriate Fehonda thermal pad involves matching the pad's characteristics to the specific needs of the component and application. As a general rule, higher heat output demands higher thermal conductivity. The gap size between the component and its heatsink will dictate the necessary thickness, and for safety, electrically non-conductive pads are almost always the preferred choice in consumer electronics. The need for precise thickness cannot be overstated, especially in modern GPUs and laptops, where an incorrect choice can lead to worsened temperatures or even physical strain on components. Fehonda's provision of 0.25mm thickness increments is a direct and effective solution to this common user challenge.

A. CPUs (Central Processing Units)

Modern CPUs, particularly when overclocked, can be significant sources of heat.

- Interface: For the primary interface between the CPU's Integrated Heat Spreader (IHS) and the cooler base (or directly on the CPU die if the IHS is removed, a practice known as "delidding"), thermal paste like Fehonda's TG-8 & TR50L grease is often chosen due to its ability to achieve an extremely thin bond line.

- Motherboard VRMs: The Voltage Regulator Modules (VRMs) on the motherboard that power the CPU also generate heat and often use thermal pads for cooling. These may require thicker pads depending on the heatsink design.

B. GPUs & VRAM (Graphics Processing Units & Video RAM)

Graphics cards are among the most thermally demanding components in a PC. Thermal pads are extensively used on VRAM chips and VRM components that surround the GPU die itself.

- Recommended Pads: Fehonda's 12.8W/mK or 15W/mK series pads are ideal for these applications.

- Thickness: The required thickness can vary dramatically between different graphics card models and even between different components on the same card (often ranging from 0.5mm to 3.0mm). Fehonda's 0.25mm thickness increments are particularly valuable here. Users frequently seek specific thickness guidance for their particular card model.

- Conformability: The inherent softness and conformability of Fehonda pads are highly beneficial due to the varying heights of VRAM chips and VRM components on GPU PCBs.

- Putty Alternative: Fehonda LTP81 or LTP65 thermal putty can also be an excellent choice for VRAM and VRMs, especially when dealing with highly irregular gap heights.

C. SSDs (Solid State Drives, especially M.2 NVMe)

M.2 NVMe SSDs, known for their high speeds, can also generate considerable heat, leading to thermal throttling and reduced performance if not adequately cooled.

- Recommended Pads: Fehonda pads, such as the 8W/mK or 12.8W/mK series, can significantly improve SSD temperatures.

- Thickness: Common thicknesses for M.2 SSD applications range from 0.5mm to 1.75mm.

- Application: Pads are typically applied between the SSD controller and NAND flash chips and an accompanying heatsink. While the highest W/mK pad might seem like the obvious choice, an 8W/mK or 12.8W/mK Fehonda pad can often be perfectly adequate and more cost-effective for SSDs, especially if the heatsink design or system airflow is the primary limiting factor in cooling.

D. Laptops & Gaming Consoles

These devices are characterized by their compact designs and significant internal heat generation from powerful CPUs and GPUs.

- Upgrade Potential: Fehonda thermal pads offer a substantial upgrade over the often lower-quality stock thermal interface materials found in these devices.

- Thickness & Softness: Thicknesses typically range from 0.5mm to 1.5mm. The softness and conformability of Fehonda pads are crucial due to the tight tolerances and varied component heights within these compact chassis.

- Applicable Components: Suitable for CPUs, GPUs, VRAM, and other heat-producing components. Fehonda 15W/mK pads are specifically mentioned as being well-suited for gaming laptop cooling solutions.

E. Other High-Heat Electronic Components

The versatility of Fehonda thermal pads extends to a wide range of other electronic components and systems that require effective thermal management. This includes:

- Power MOSFETs, motherboard chipsets, analog ICs, microcontrollers.

- LED lighting systems, power supplies.

- Automotive electronics, drone systems. Fehonda's broad selection of thermal conductivities and thicknesses makes their pads adaptable to these diverse needs.

Fehonda Thermal Pad Selection Matrix

To simplify the selection process, the following table provides quick recommendations:

| Application | Key Challenges | Recommended Fehonda Series (W/mK) | Typical Thickness Range (mm) | Notes/Considerations |

|---|---|---|---|---|

| CPU (IHS to Cooler) | Minimal gap, high heat flux | Paste (TG-8 & TR50L) | 0.25mm | Paste often preferred for thinnest bond line. Ensure IHS is flat. |

| GPU (VRAM) | Multiple chips, varying heights, high heat | Pad(12.8,15 )or Putty (LTP81/LTP65) | 0.5−3.0 (model specific, 0.25 increments) | Precise thickness is critical. Softness aids conformability. Non-conductive essential. |

| GPU (VRM) | Varying component shapes/heights, moderate heat | Pad(8,12.8) or Putty(LTP81/LTP65) | 1.0−3.0 (model specific, 0.25 increments) | Softness and conformability are key. Non-conductive. |

| M.2 NVMe SSD | Controller & NAND heat, potential throttling | Pad(8,12.8) | 0.5−1.75 | Improves sustained performance. Often used with an SSD heatsink. |

| Laptop CPU/GPU | Compact space, high heat, varied component heights | Pad(12.8,15 ) | 0.5−1.5 | Softness and precise thickness are very important. Upgrade over stock pads. |

| Gaming Console Internals | CPU/APU, RAM, VRM cooling in confined space | Pad(8,12.8,15 ) | 0.5−1.5 | Can significantly improve cooling and reduce fan noise. |

| General Electronics | Chipsets, ICs, Power Modules | Pad(8,12.8) | 0.5−2.0 | Versatile application based on heat output and gap size. |

Where to Buy Genuine Fehonda Thermal Pads

Ensuring the authenticity of thermal pads is crucial for achieving the expected performance and safety. The presence of multiple online storefronts can sometimes lead to confusion, so clarity on official purchasing channels is important.

A. Official B2C Channel: Fehonda ThermalTechPro Store on AliExpress

The primary and most direct channel for consumers to purchase genuine Fehonda thermal pads is the FEHONDA ThermalTechPro Store on AliExpress. Purchasing from this official storefront offers several benefits:

- Guaranteed Authenticity: Direct sourcing minimizes the risk of counterfeit products.

- Full Product Range: Access to the complete selection of Fehonda thermal pads, including all conductivity ratings and thickness options.

- Direct Customer Support: The ability to communicate directly with Fehonda's support team for inquiries or assistance.

B. Fehonda Official Website (Fehonda.com / Feihongda Technology)

The corporate website, Fehonda.com, serves primarily as a source of information about Feihongda Technology's broader capabilities in electromagnetic shielding, thermal conductive materials, company profile, and B2B solutions. While not a direct B2C sales platform, it allows users to learn more about the company's expertise and manufacturing prowess.

Quick Guide: Installing Your Fehonda Thermal Pads for Optimal Results

Proper installation is key to maximizing the effectiveness of your Fehonda thermal pads. Here’s a step-by-step guide:

A. Preparation is Key:

- Gather Your Tools: You will need your Fehonda thermal pad, a precise measuring tool (ruler or calipers), a sharp cutting tool (scissors or a craft knife), lint-free cloths (microfiber is ideal), and high-purity isopropyl alcohol (90% or higher concentration is recommended). An anti-static wrist strap is also advisable to prevent electrostatic discharge (ESD) damage to sensitive components.

- Safety First: Power off your computer or electronic device completely and unplug it from the power source. Allow all components to cool down to room temperature before proceeding.

B. Clean Surfaces Thoroughly:

- Remove Heatsink: Carefully detach the heatsink or cooling assembly from the component(s) you intend to apply the new thermal pads to.

- Remove Old Material: Meticulously clean off any old thermal paste or existing thermal pads from both the component surface (e.g., CPU die, GPU die, VRAM chips, SSD controller/NAND chips) and the contact surface of the heatsink.

- Pristine Clean: Use a lint-free cloth lightly dampened with isopropyl alcohol to wipe away all residue. Continue cleaning until the surfaces are absolutely pristine and free of any contaminants. Ensure the surfaces are completely dry before applying the new pad.

- Avoid Contamination: Do not touch the cleaned surfaces with your bare fingers, as skin oils can act as insulators and impede heat transfer. This step is critical because any remaining residue or oils can significantly reduce the effectiveness of the new thermal pad.

C. Measure and Cut the Fehonda Pad:

- Accurate Measurement: Precisely measure the dimensions of the surface(s) where the thermal pad will be applied (e.g., the top surface of a VRAM chip or an SSD controller).

- Precise Cutting: Carefully cut the Fehonda thermal pad to the exact measured size using your sharp scissors or craft knife. The goal is a perfect fit that covers the entire target area without overhanging the edges. Fehonda's soft silicone-based pads are generally easy to cut, which is a user-friendly advantage over harder or more brittle materials.

D. Apply the Fehonda Pad:

- Remove Protective Film (First Side): Fehonda thermal pads come with protective film on both sides. Peel the film from ONE side of your precisely cut thermal pad piece.

- Position the Pad: Carefully align and place the exposed, slightly tacky side of the thermal pad onto the target component surface. Ensure it lies flat and makes good, even contact, without any trapped air bubbles.

- Remove Protective Film (Second Side): Once the pad is correctly positioned on the component, remove the remaining protective film from the top side of the pad.

E. Reinstall the Heatsink:

- Careful Alignment: Align the heatsink carefully over the component and the newly applied thermal pad.

- Gentle Placement: Lower the heatsink straight down onto the pad, avoiding any sliding or twisting motion, which could displace the pad or create air pockets.

- Secure Evenly: Secure the heatsink according to the manufacturer's instructions (e.g., screws, clips). If using screws, tighten them gradually in a crisscross or diagonal pattern to distribute pressure evenly across the pad and component. Do not over-tighten, as this could damage the component or the PCB.

F. Test and Monitor:

- Reassemble and Power On: Reconnect all cables and reassemble your device. Power it on.

- Temperature Check: Use appropriate hardware monitoring software (e.g., HWMonitor, Core Temp, GPU-Z) to check the temperatures of the component(s) under both idle and load conditions (e.g., by running a benchmark or demanding application). Compare these temperatures to previous readings (if available) or typical operating ranges to ensure the thermal pads are performing effectively.

Conclusion: Elevate Your System's Performance with Fehonda Thermal Solutions

Choosing the right thermal pad is a critical step in optimizing the thermal performance, stability, and longevity of your valuable electronic components. Fehonda thermal pads stand out by offering a compelling combination of superior and reliable cooling, enabled by high thermal conductivity and exceptional softness for maximum surface contact. The precision fit afforded by a wide range of thicknesses, including unique 0.25mm increments, ensures an optimal thermal interface for diverse applications. Coupled with the crucial safety feature of electrical non-conductivity and the backing of a company committed to quality, certifications, and positive expert reviews, Fehonda provides a trustworthy solution.

If you've been searching "wärmeleitpads kaufen" with the goal of achieving optimal thermal performance, reducing operating temperatures, or ensuring the long-term health of your system, Fehonda thermal solutions offer a clear path forward. They represent an investment in performance and reliability, addressing the nuanced challenges of modern electronic cooling with thoughtfully engineered products.

Upgrade your system's cooling capabilities today. Explore the full range of Fehonda thermal pads at the official FEHONDA ThermalTechPro Store on AliExpress and experience the Fehonda difference! Empower your electronics to perform at their best, safeguarded by advanced thermal management.

Frequently Asked Questions (FAQ)

Q1: How often should I replace thermal pads?

Generally, thermal pads should be considered for replacement every 2 to 5 years, depending on the quality of the pad, the intensity of device usage, and the operating environment. It's also highly recommended to replace thermal pads whenever a heatsink is removed for maintenance or component upgrades, or if you notice a consistent increase in component operating temperatures under normal load.

Q2: Are Fehonda thermal pads reusable?

As a general rule, thermal pads are not designed to be reusable. Once a pad has been compressed and subjected to heat cycles, its structural integrity and thermal transfer properties can be compromised if it's removed and reinstalled. For optimal performance, it is always best to use a fresh piece of thermal pad if the heatsink is detached.

Q3: What's the difference between thermal pads and thermal paste? Which one should I use?

Both thermal pads and thermal paste are thermal interface materials, but they suit different applications.

- Thermal Pads: Best for filling larger or uneven gaps between a component and its heatsink (e.g., VRAM chips, VRMs, M.2 SSDs). They are generally easier to apply, less messy, and come in specific thicknesses.

- Thermal Paste: Ideal for creating an ultra-thin thermal interface where the surfaces of the component (like a CPU IHS or GPU die) and the heatsink are very flat and make close contact. Paste can achieve a thinner bond line than pads, potentially offering slightly better thermal conductivity in such scenarios. Fehonda offers both thermal pad and thermal paste solutions to cater to these different needs.

Q4: Can I stack Fehonda thermal pads to achieve a greater thickness?

Thermal pads can be stacked up to a certain limit without significant performance loss, it is generally recommended to use a single thermal pad of the correct, precise thickness whenever possible. Stacking pads can introduce additional interface layers and potentially trap air, which might impede thermal transfer. Always refer to Fehonda's specific product guidelines. Given Fehonda's wide range of thicknesses, including 0.25mm increments, finding a single pad of the appropriate dimension is often feasible.

Q5: Are Fehonda thermal pads electrically conductive?

No, Fehonda thermal pads sold for consumer electronics applications (like CPUs, GPUs, SSDs, etc.) are specifically designed and marketed as being electrically non-conductive. This is a critical safety feature to prevent accidental short circuits on your valuable components