Efficient thermal management is critical in modern electronic devices and industrial applications. Thermal conductive adhesives, high-performance silicone-based materials, are widely used to facilitate effective heat dissipation. Primarily, these adhesives fill the gaps between electronic components and heat sinks, increasing the contact area and reducing thermal resistance, thereby significantly improving cooling efficiency. With their excellent thermal conductivity, electrical insulation, flexibility, and weather resistance, they have become essential materials for managing heat in electronic equipment.

Thermal Conductive Adhesives Types Benefits and Applications

Types of Thermal Conductive Adhesives from FEHONDA

We offer a range of thermal conductive adhesives tailored to diverse application needs and usage methods:

Thermal Grease This viscous thermal interface material is typically used to fill the microscopic gaps between processors and heat sinks. It boasts good thermal and electrical insulation properties, is easy to apply, and finds widespread use in electronic devices like computers, mobile phones, and LED lighting.

![]()

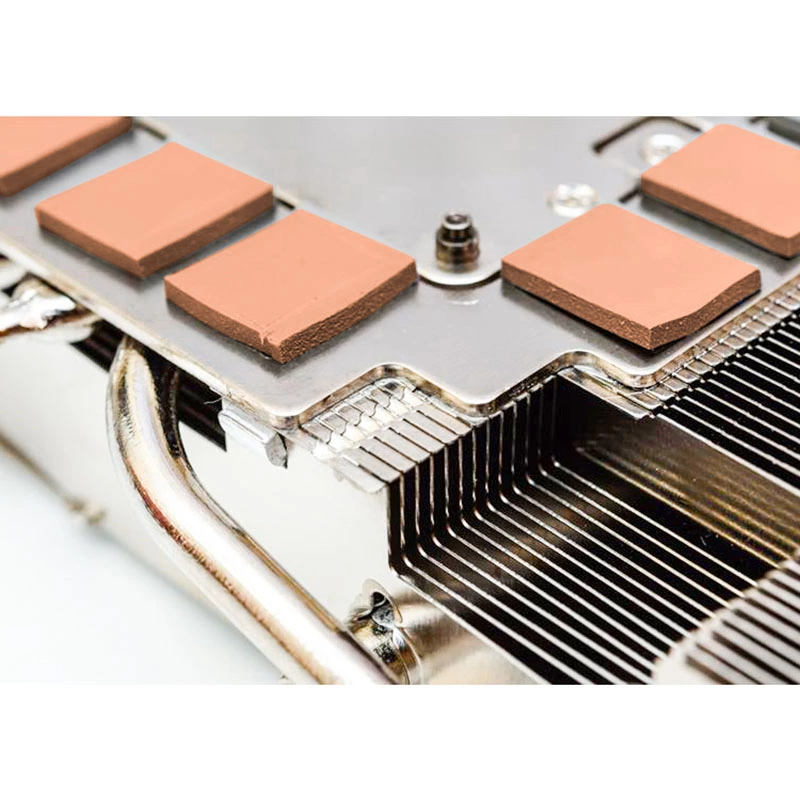

Thermal Pads These flexible sheets, made from thermal conductive silicone materials, are commonly used to fill gaps between irregular surfaces. They exhibit excellent compression and rebound properties, ensuring even pressure and heat distribution, often found in power modules, power semiconductors, and automotive electronics.

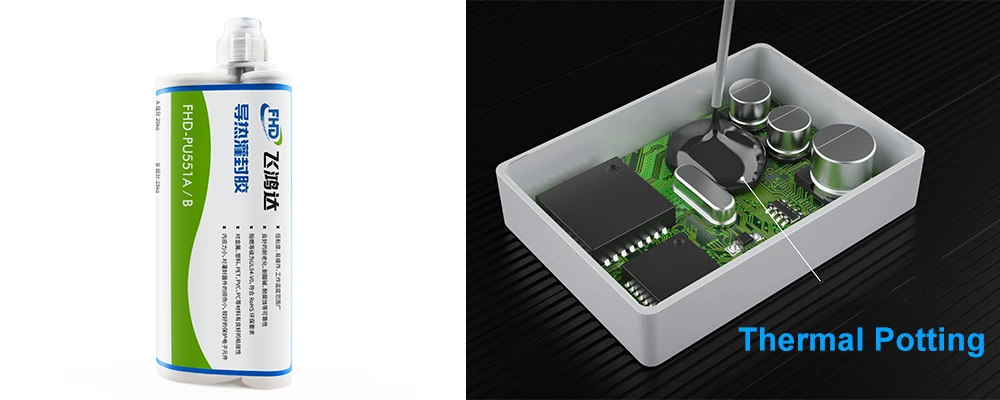

Thermal Potting These liquid thermal silicone materials are applied through potting to fill voids between electronic components and housings. Upon curing, they form a solid with defined strength and elasticity, offering superior thermal conductivity and protective properties, ideal for encapsulating high-power electronic devices, transformers, and sensors.

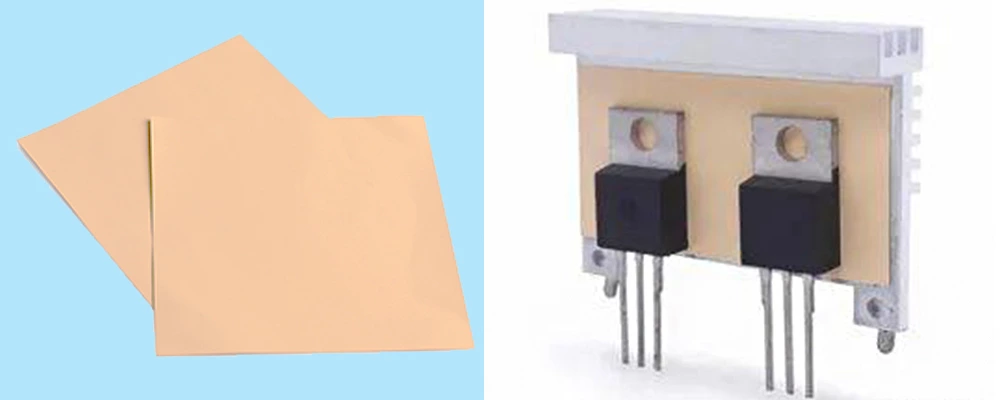

Thermal Conductive Insulators These thin products, made from thermal conductive silicone materials, featuring excellent thermal and electrical insulation. They are suitable for attaching between heat sources and heat sinks, widely used in electronic products, communication equipment, and household appliances.

Characteristics and Advantages of Our Thermal Conductive Adhesives

Our thermal conductive adhesives possess numerous outstanding characteristics, making them an ideal choice for electronic device thermal management. Taking our FHD 8517 high thermal conductivity silicone adhesive as an example, the key properties and advantages include:

- Single-component, thixotropic fluid

- Thermal Conductivity: 1.0 W/mK(Support Custom More)

- Gray silicone adhesive

- Rapid heat curing

- Adhesion to most substrates without primer (e.g., metals, glass, ceramics)

- Addition cure system, no curing byproducts

- ROHS/REACH certified

- UL 94 V-0 flame retardant compliant

- Maintains elasticity and stability in the temperature range of -50℃ to +280℃

Advantages Compared to Other Thermal Materials

We understand the nuances of different thermal management solutions:

- Thermal Pads: Require cutting and screw fixation. Our adhesives offer a bonding solution, eliminating the need for mechanical fasteners in many applications.

- Gap Fillers: Lack inherent adhesion and behave like cushioning pads after curing. Our adhesives provide a strong bond and efficient thermal transfer.

- RTV Thermal Silicone: Room temperature vulcanizing, with very long curing times. We offer rapid heat-curing options for faster production processes.

- Thermal Grease: Prone to oil bleeding at high temperatures and can dry out over long-term aging. Our adhesives offer stable, long-lasting performance.

- FHD 8517-S10 (Example): Cures at 23℃ for 10 minutes, forming a high thermal conductivity elastic buffer. We offer comparable and potentially faster curing options with strong bonding.

Applications of Our Thermal Conductive Adhesives

Our thermal conductive adhesives are crucial in various industries:

Computer and Communication Equipment Used for heat dissipation in processors, graphics cards, and chipsets. Thermal grease is used between the CPU and heat sink, while silicone pads/sheets cool other chips. We provide solutions for both.

LED Lighting Fills gaps between LED chips and heat sink substrates. Potting compounds protect driver power supplies, ensuring reliable operation. We offer suitable adhesives for these applications.

Power Modules and Transformers Potting compounds provide encapsulation and protection for internal components, while silicone pads fill gaps. We have products designed for the demanding thermal management needs of power electronics.

Automotive Electronics Used for heat dissipation in electric vehicle batteries and control modules, offering high and low-temperature resistance and anti-aging properties. We provide robust thermal solutions for the automotive sector.

Industrial Control Equipment Fills gaps between circuit boards and heat sinks, capable of withstanding high-temperature and harsh environments. We offer reliable thermal adhesives for industrial applications.

How to Use Our Thermal Conductive Adhesives

We recommend the following application guidelines:

Surface Pre-treatment Clean substrates with solvents (alcohol, SIPA CLEANER 20, etc.). Difficult-to-bond materials may require a primer (e.g., SIPA 1262/1269). We offer cleaning and primer solutions.

Stirring After prolonged storage, extrude any surface liquid and mix thoroughly.

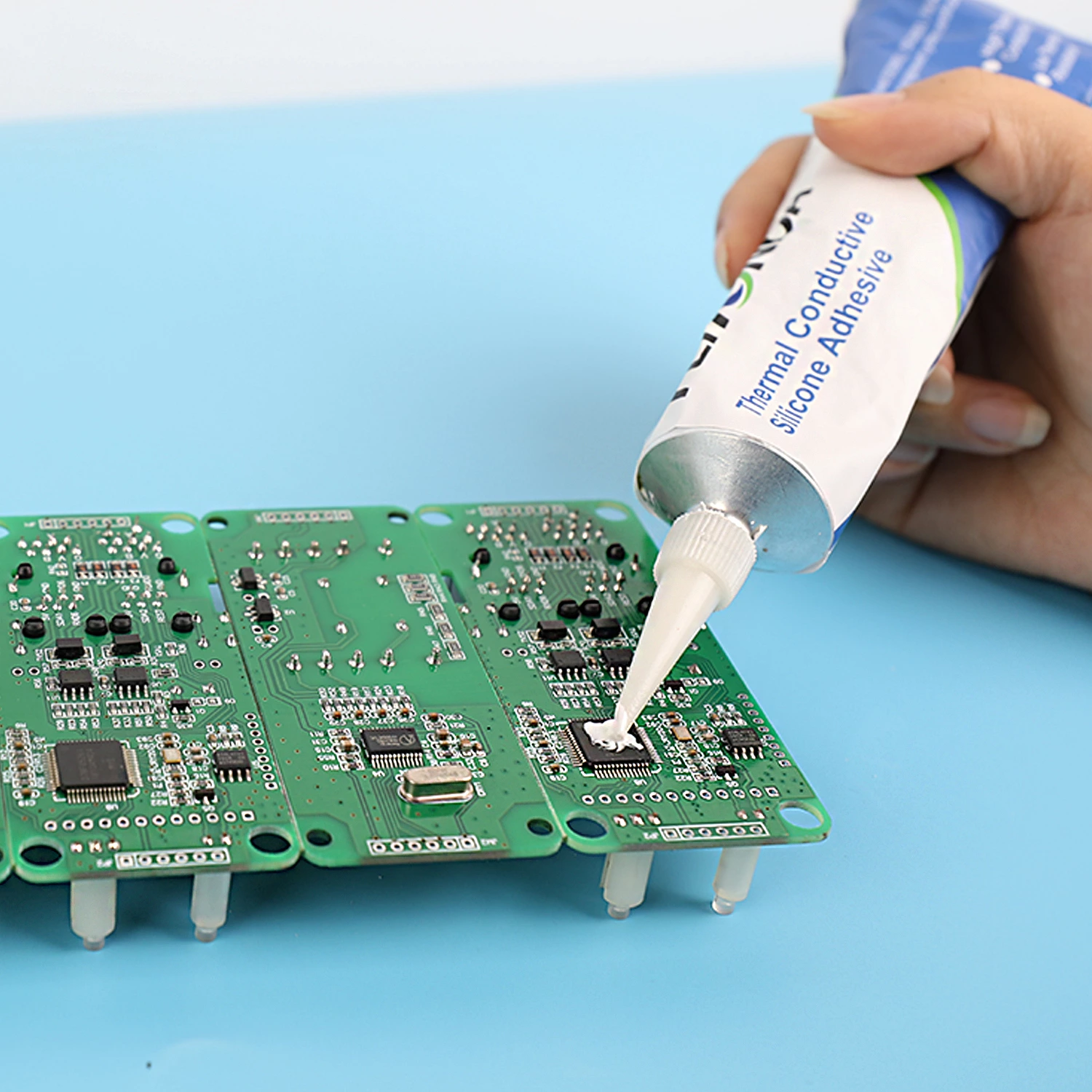

Application Apply using dispensing equipment or stencil printing.

Curing Recommended curing conditions:

- 150℃ for 25 minutes

- 135℃ for 35 minutes

- 120℃ for 60 minutes

Avoid exposure above 200℃ before curing to prevent bubbles.

Compatibility Avoid contact with substances that inhibit curing, such as sulfur, amines, and organotin compounds.

Selecting and Purchasing Our Thermal Conductive Adhesives

We advise considering the following factors during selection:

- Thermal Performance: Choose the thermal conductivity based on your heat dissipation requirements.

- Electrical Insulation: Consider electrical insulation parameters for high-voltage applications.

- Operating Environment: Ensure temperature and weather resistance match the application scenario.

- Ease of Operation: Select types with fast curing times and easy application.

- Brand Quality: Prioritize reputable brands with complete certifications (like our FEHONDA series).

Future Development Trends in Thermal Conductive Adhesives - Our Vision

We anticipate the following future trends in thermal conductive adhesives:

- Higher Thermal Performance: Development of materials with even higher thermal conductivity.

- Enhanced Electrical Insulation: Adapting to high-voltage and high-frequency environments.

- Improved Environmental Adaptability: Resistance to extreme temperatures and aging.

- Increased Operational Convenience: Optimization of dispensing processes and equipment.

- Green and Environmentally Friendly: Reducing harmful substances and complying with environmental regulations.

Conclusion

Thermal conductive adhesives are core materials for electronic thermal management. Through continuous innovation, we believe their application in high-power devices, automotive electronics, and other fields will continue to expand, providing crucial support for efficient heat dissipation and device reliability. Choose our FEHONDA solutions for your thermal management needs.