Ensuring efficient heat dissipation is paramount for the longevity and optimal performance of your Central Processing Unit (CPU). Without proper cooling, your CPU can overheat, leading to performance throttling, system instability, and even permanent damage. Two primary thermal interface materials (TIMs) are commonly employed to bridge the microscopic gaps between the CPU's integrated heat spreader (IHS) and the cooler's baseplate: thermal pads and thermal paste (also known as thermal grease or compound).

Thermal Pad vs Thermal Paste for CPU,Which is Better?

CPU Cooling Showdown: Thermal Pad vs. Thermal Paste - Which Reigns Supreme?

Choosing the right TIM can significantly impact your CPU's operating temperatures. This comprehensive guide delves deep into the characteristics, advantages, disadvantages, and application scenarios of both thermal pads and thermal paste to help you make an informed decision for your specific needs.

Understanding the Basics: Thermal Interface Materials and Their Role

Before we dive into the specifics of thermal pads and thermal paste, it's crucial to understand why TIMs are necessary in the first place. The surfaces of both the CPU's IHS and the cooler's baseplate, while appearing smooth to the naked eye, are actually riddled with microscopic imperfections. These tiny air gaps are poor conductors of heat, hindering efficient heat transfer between the two surfaces.

Thermal interface materials work by filling these microscopic voids, creating a more thermally conductive pathway for heat to travel from the CPU to the cooler, where it can then be dissipated into the surrounding environment.

Thermal Pads: A Convenient and Reliable Solution

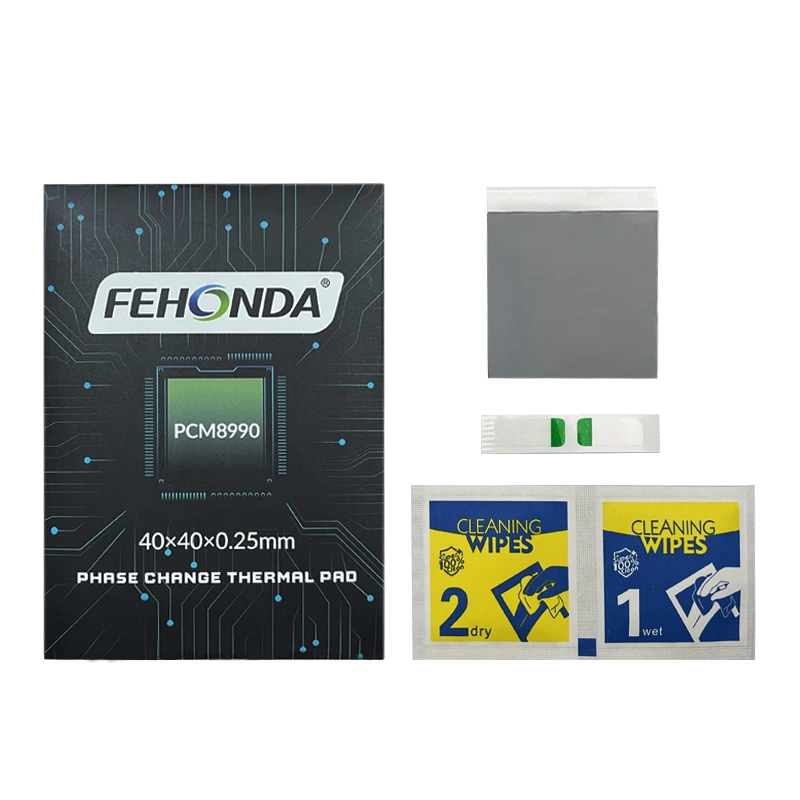

Thermal pads are essentially solid blocks or sheets of thermally conductive material, often made from silicone or other elastomers embedded with thermally conductive particles such as ceramics, graphite, or metal oxides. They are pre-cut to various shapes and thicknesses, making them relatively easy to handle and install.

Advantages of Thermal Pads:

- Ease of Application: One of the most significant advantages of thermal pads is their ease of application. They require no spreading and can be simply placed onto the CPU IHS before the cooler is mounted. This makes them ideal for beginners and high-volume manufacturing where speed and consistency are crucial.

- Cleanliness: Thermal pads are generally cleaner to work with compared to thermal paste. There's no risk of messy spills or the need for meticulous cleanup.

- Reusability (Sometimes): In some cases, if the cooler is removed and reinstalled carefully, the thermal pad might still be usable, although it's generally recommended to replace it for optimal performance.

- Consistent Thickness: Pre-cut thermal pads offer a consistent thickness, ensuring even pressure distribution between the CPU and the cooler.

- Non-Conductive Options: Many thermal pads are electrically non-conductive, reducing the risk of short circuits if they happen to come into contact with other components on the motherboard. This is a significant safety advantage, especially for less experienced users.

- Durability and Lifespan: High-quality thermal pads boast excellent durability and a long lifespan, often lasting for several years without significant degradation in performance.

Disadvantages of Thermal Pads:

- Potentially Lower Thermal Conductivity: Generally, thermal pads tend to have lower thermal conductivity compared to high-end thermal pastes. This means they might not be as effective at transferring heat, potentially resulting in slightly higher CPU temperatures under heavy load.

- Less Conformity to Surface Imperfections: While they fill gaps, thermal pads might not conform to microscopic surface imperfections as effectively as a liquid-based thermal paste, potentially leaving some minute air pockets.

- Thickness Limitations: The fixed thickness of thermal pads might not be ideal for all CPU and cooler combinations, potentially leading to suboptimal contact pressure in some scenarios.

- Performance Degradation Under High Pressure: In some cases, excessive mounting pressure can cause the thermal pad to deform or squeeze out, potentially reducing its effectiveness over time.

Thermal Paste: The Enthusiast's Choice for Maximum Performance

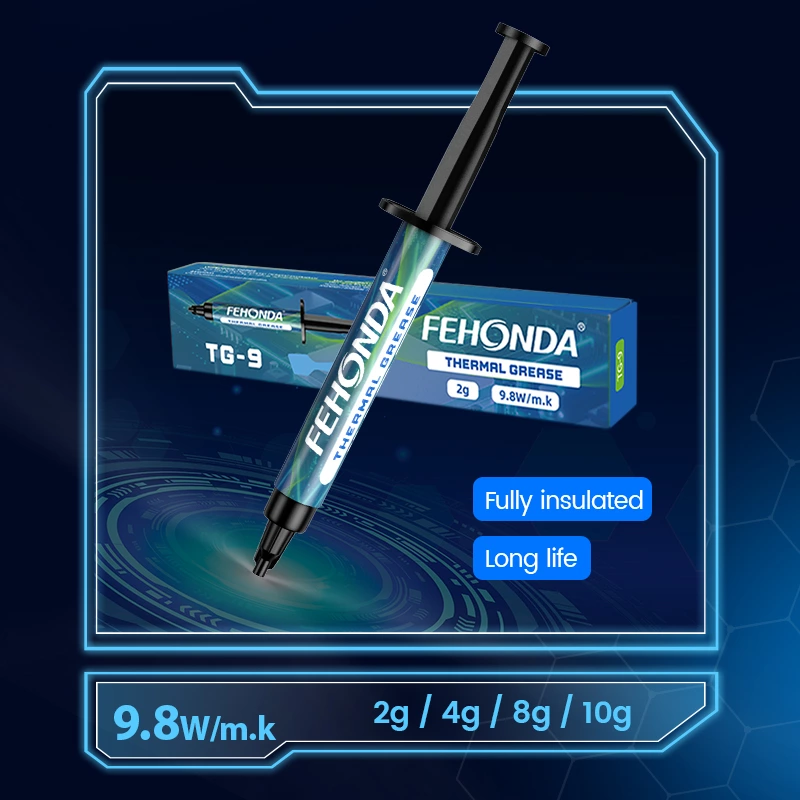

Thermal paste is a viscous compound typically composed of a base material (such as silicone, carbon, or metal) mixed with thermally conductive fillers like metal particles (e.g., silver, copper, aluminum oxide, zinc oxide, boron nitride, or diamond dust). It is applied as a thin layer onto the CPU IHS before the cooler is installed.

Advantages of Thermal Paste:

- Superior Thermal Conductivity: High-quality thermal pastes generally offer significantly higher thermal conductivity compared to thermal pads. This translates to more efficient heat transfer and potentially lower CPU temperatures, especially under demanding workloads.

- Excellent Conformity to Surface Imperfections: The liquid or semi-liquid nature of thermal paste allows it to conform perfectly to the microscopic irregularities on both the CPU IHS and the cooler base, maximizing contact area and minimizing air gaps.

- Thin and Optimized Application: When applied correctly, thermal paste forms an extremely thin layer, minimizing the thermal resistance between the CPU and the cooler. Users can optimize the application thickness for the best results.

- Wide Range of Performance Options: A vast array of thermal pastes are available, catering to different performance levels and budgets, from basic compounds to extreme performance options for overclocking enthusiasts.

Disadvantages of Thermal Paste:

- Messy Application: Applying thermal paste can be messy and requires careful technique to ensure even coverage and avoid getting it on other components.

- Potential for Electrical Conductivity: Some high-performance thermal pastes contain conductive metal particles, posing a risk of short circuits if they accidentally spread onto sensitive motherboard components. Electrically non-conductive options are available but may not offer the absolute highest thermal performance.

- Requires Skill and Experience: Achieving optimal results with thermal paste requires some skill and experience in applying the correct amount and ensuring even distribution.

- One-Time Use: Once the cooler is removed, the thermal paste needs to be reapplied as the original application will likely be disturbed and may not provide optimal contact upon reinstallation.

- Potential for Pump-Out Effect: Over time, some thermal pastes can experience a phenomenon called "pump-out," where thermal cycling and pressure cause the paste to migrate away from the center of the IHS, reducing its effectiveness. High-quality pastes are often formulated to minimize this effect.

Key Considerations When Choosing Between Thermal Pads and Thermal Paste:

To determine whether a thermal pad or thermal paste is better for your CPU, consider the following factors:

- Cooling Requirements: For basic systems with moderate cooling needs and stock coolers, a high-quality thermal pad might be sufficient and offers ease of use. However, for high-performance CPUs, overclocking, or systems with demanding workloads, the superior thermal conductivity of a good thermal paste is generally recommended to achieve lower temperatures.

- User Skill Level: If you are a beginner or prefer a hassle-free installation, a thermal pad is the simpler option. Applying thermal paste correctly requires more care and attention to detail.

- Safety Concerns: If you are concerned about the risk of electrical shorts, opting for a non-conductive thermal pad is a safer choice. Non-conductive thermal pastes are also available but should be explicitly chosen.

- Budget: Thermal pads and thermal pastes are available at various price points. Generally, high-performance thermal pastes tend to be more expensive than standard thermal pads. However, the cost difference might be negligible compared to the potential benefits in terms of CPU lifespan and performance.

- Longevity and Maintenance: High-quality thermal pads can offer excellent longevity with minimal performance degradation. Thermal paste typically needs to be reapplied whenever the cooler is removed. The "pump-out" effect can also necessitate more frequent reapplication for some pastes.

- Specific Application: In some industrial or embedded applications, thermal pads might be preferred for their robustness, ease of assembly, and consistent performance over extended periods.

Our Recommendation:

Choosing the right thermal interface material is crucial for optimal CPU cooling. While thermal pads offer convenience and ease of use, for users seeking the absolute best thermal performance, especially for high-end CPUs and overclocking, a high-quality thermal paste is generally the preferred choice.

However, for mainstream systems where ease of installation and safety are primary concerns, a reliable and high-quality thermal pad can provide adequate cooling performance without the mess and potential risks associated with thermal paste.

Ultimately, the best choice depends on your individual needs, technical expertise, and the specific requirements of your system. We recommend considering all the factors discussed above before making your decision.

Conclusion:

The debate between thermal pads and thermal paste for CPU cooling boils down to a trade-off between ease of use and maximum thermal performance. Thermal pads offer a clean, convenient, and often safer solution for many users, while thermal paste, when applied correctly, typically provides superior heat transfer capabilities. By understanding the characteristics, advantages, and disadvantages of each, you can make an informed decision that best suits your CPU cooling needs and ensures the long-term stability and performance of your valuable hardware. For a wide selection of high-quality thermal interface materials, be sure to explore the available options.