What are Thermal Interface Materials? FEHONDA Explains

Thermal Interface Materials (TIMs) serve the core function of bridging the minute gaps, surface roughness, and air pockets between two contacting surfaces, thereby dramatically improving heat conduction. It's well-established that air is an excellent insulator, severely hindering heat dissipation. Consequently, TIMs are designed to enhance heat transfer efficiency by offering a low thermal resistance pathway, leading to more effective cooling.

The thermal conductivity of a TIM is the key determinant of its heat dissipation performance. High thermal conductivity ensures rapid and efficient heat transfer, meeting the cooling demands of electronic devices.

Ideal Thermal Interface Materials should possess the following characteristics, which FEHONDA consistently prioritizes in our product development:

Thermal interface materials come in various forms, including Thermal Pads, Thermal Grease, and Thermal Paste. They are generally easy to handle and install, offering a range of thickness options to suit diverse application requirements.

FEHONDA Insights: What are Thermal Pads?

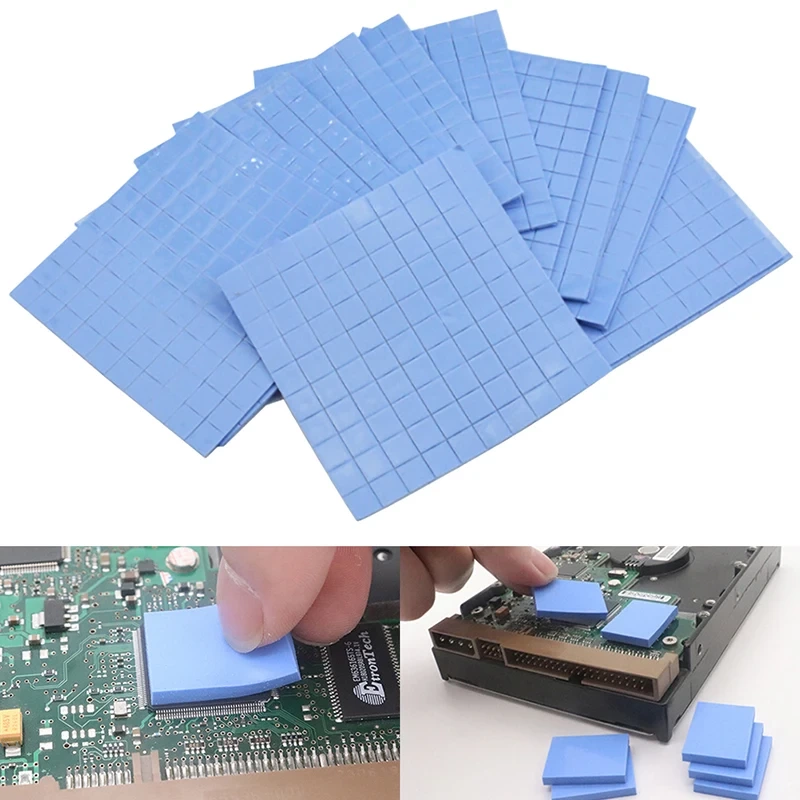

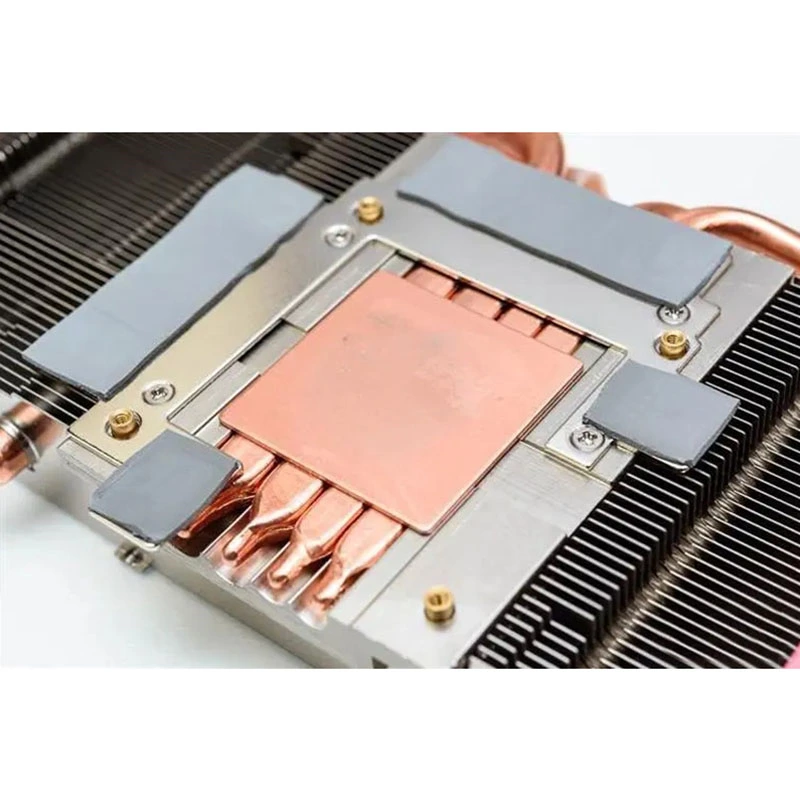

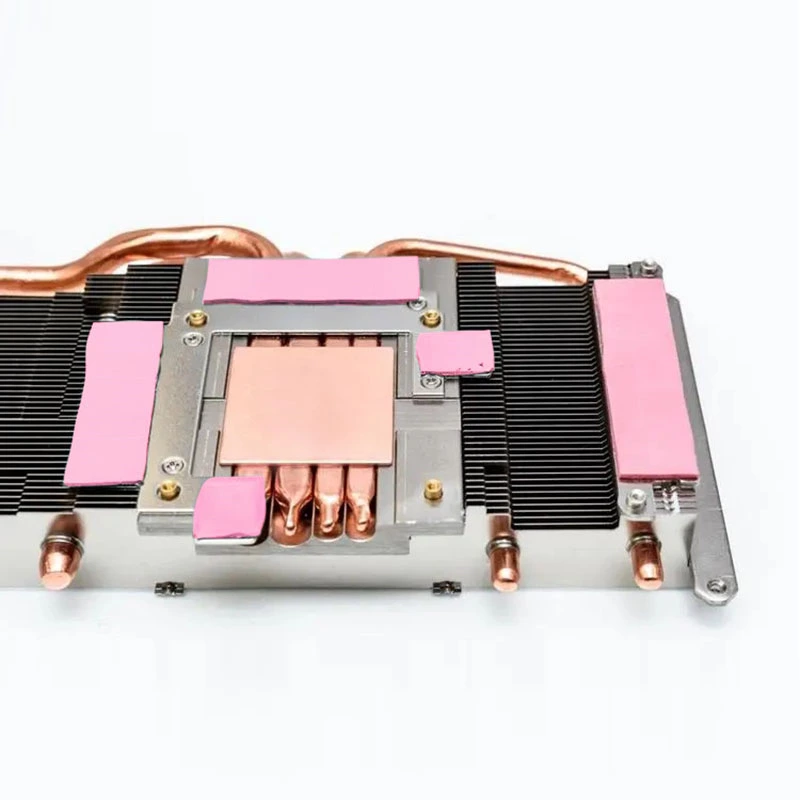

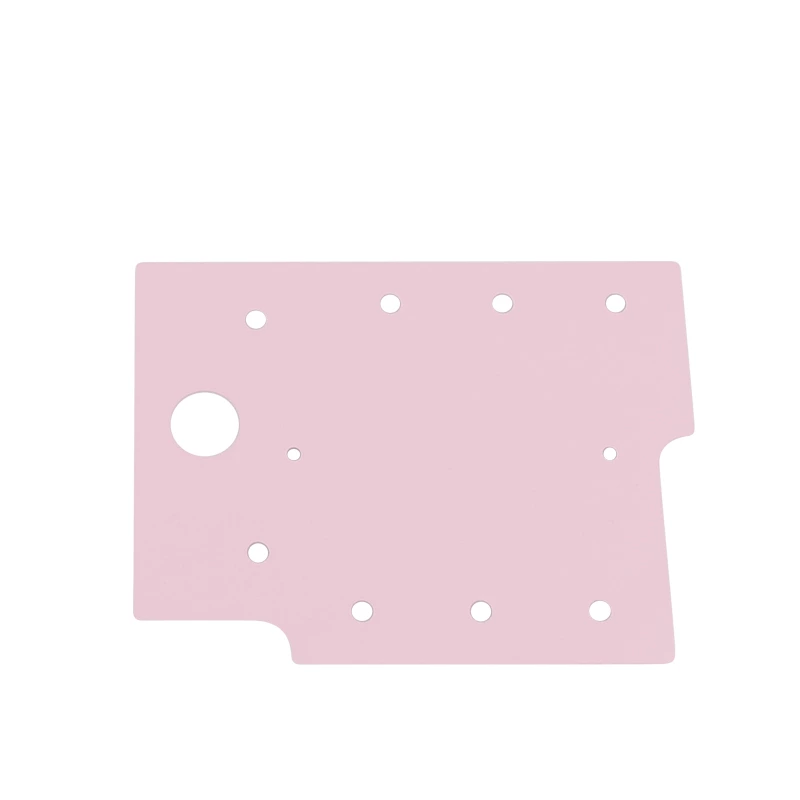

Thermal Pads are a significant type of Thermal Interface Material. These pads are widely utilized in the thermal interface between PCB components or electronic devices, such as microprocessors and semiconductors, and heat sinks (devices or substances used to absorb excess heat). Thermal pads are particularly beneficial when traditional thermal grease or thermal paste prove ineffective due to uneven surfaces, rough textures, or the presence of substantial air gaps.

FEHONDA offers thermal pads in a variety of thicknesses, softness levels, filler materials, and thermal conductivity ratings. The material composition of the pad directly dictates the rate of heat transfer, typically measured by thermal conductivity (W/m·K). Higher thermal conductivity values indicate more efficient heat transfer.

Thermal pads are also known as Gap Fillers, Thermal Transfer Pads, or Thermal Gap Pads.

Why Use FEHONDA Thermal Pads?

The primary purpose of FEHONDA Thermal Pads is to fill the air gaps caused by imperfectly smooth or flat surfaces that require close contact. Conversely, thermal pads might not be necessary between perfectly flat and smooth surfaces. FEHONDA Thermal Pads effectively conduct heat, preventing overheating and potential damage to devices.

FEHONDA Thermal Pads offer the following notable advantages:

-

Easy to Cut to Size

-

Easy to Handle

-

No Pump-Out or Dry-Out Issues

-

Wide Range of Thickness Options Available

-

Unaffected by Humidity and Harsh Environments

Of course, FEHONDA also acknowledges the potential limitations of thermal pads:

-

Potential for Delamination

-

Generally Lower Thermal Conductivity Compared to Thermal Paste

-

May Induce Some Mechanical Stress

-

Less Effective at Filling Minor Surface Irregularities Compared to Thermal Paste

-

Clamping Force May Be Required for Optimal Performance

When Should You Choose FEHONDA Thermal Pads?

FEHONDA Thermal Pads find extensive use in various electronic devices and cooling scenarios, including but not limited to:

FEHONDA Tech Explained: Effective Thermal Resistance

Effective Thermal Resistance is the total resistance to heat transfer across an interface. It is defined by the following equation:

Reffective=kTIM×AtTIM+Rc1+Rc2

Where:

-

Reffective: Effective Thermal Resistance

-

tTIM: Thickness of the TIM (Thermal Pad Thickness)

-

kTIM: Thermal Conductivity of the TIM (Thermal Pad Conductivity)

-

A: Contact Area

-

Rc1: Thermal Contact Resistance at the First Surface Boundary

-

Rc2: Thermal Contact Resistance at the Second Surface Boundary

Some components of effective thermal resistance, such as contact resistance, can be challenging to calculate precisely. However, understanding the concept of effective thermal resistance is crucial for optimizing cooling. FEHONDA recommends focusing on the following key points to minimize effective thermal resistance:

-

Minimize Effective Thermal Resistance: The thermal interface should have the lowest possible effective thermal resistance. Lower resistance leads to more efficient heat transfer across the interface.

-

Reduce Bond Line Thickness (BLT): A thinner bond line thickness generally results in better heat transfer.

-

Select High Thermal Conductivity TIMs: To enhance thermal performance, choose TIMs with high thermal conductivity. FEHONDA offers a variety of high-conductivity thermal pads for your needs.

-

Optimize Material Compression Modulus: For better gap filling, the material should have an appropriate compression modulus. Softer materials deform more readily to fill irregularities, improving heat transfer. In contrast, firmer materials may be more suitable for use between two flat, smooth surfaces where higher clamping pressure can be applied without excessive deformation.

-

Apply Appropriate Clamping Pressure: Depending on the type of TIM used, apply the highest possible clamping pressure. Forcing the TIM more tightly into surface gaps or irregularities can enhance heat transfer.

Types of FEHONDA Thermal Pads

"Thermal Pad" is a general term often used to refer to any non-fluid thermal interface material. FEHONDA offers various types of thermal pads to meet diverse application requirements:

-

Conductive Thermal Pads: These pads lack an electrical insulation layer, meaning both heat and electricity can be transferred between the two surfaces or devices. They are typically one of the thinnest thermal pad materials available.

-

Non-Conductive Thermal Pads: These pads facilitate heat transfer without conducting electricity. They are usually thicker to incorporate electrical insulation materials, which may slightly reduce their thermal performance. Therefore, they should only be used when electrical isolation is critical.

-

Thermal Pads for Well-Mated Surfaces: These pads can be either conductive or non-conductive but are specifically designed for relatively smooth, well-matched surfaces. They are thinner and lighter than their counterparts designed for mismatched surfaces.

-

Thermal Pads for Poorly-Mated Surfaces: These pads are specifically designed to fill irregular or large gaps between components. They are typically thicker and more compressible, making them unsuitable for well-mated surfaces where better thermal transfer is required.

FEHONDA Analysis: Lifespan of Thermal Pads

FEHONDA reminds you that the performance of thermal pads can gradually degrade over time, and the potential for this degradation should be considered when designing cooling solutions. The rate of performance decline depends on several influencing factors, such as the amount of heat the pads are subjected to and the environment in which they operate.

Common reasons for the degradation of thermal material performance include:

-

Natural Degradation Over Time

-

Dry-Out: Refers to the loss of pliability, preventing the pad from shifting during thermal expansion and contraction to maintain contact with the surfaces.

-

Pump-Out: A term used to describe the expulsion of thermal interface material due to thermal expansion and contraction processes. While this issue typically affects fluid TIMs like thermal paste, understanding its principle helps in grasping the overall characteristics of TIMs.

However, it is important to note that thermal pads are generally considered a one-time solution. If a heat sink is removed from its mounted position, it is recommended to replace the thermal pad with a new one. This is because the heat from the operating processor causes the thermal pad to conform to the top, and removing the heat sink will create new gaps between the surfaces upon reinstallation.

FEHONDA recognizes that both thermal pads and thermal paste offer numerous benefits, but choosing the better solution for certain applications or environments can be challenging. Let's compare these two common TIMs:

Thermal paste conforms to the surfaces it is applied to, filling all inconsistencies in the material and eliminating any air gaps. This typically results in higher thermal conductivity and heat transfer because the thermal paste effectively creates a continuous coating over the surfaces between components. In contrast, thermal pads offer a similar function but may not eliminate the smallest air gaps. While thermal paste can adapt to the texture of the surface, pads compress to the surface, but the coverage may not be as intimate as with thermal paste.

Another key difference lies in the ease of application. Thermal pads are relatively simple and straightforward to use. They often have an adhesive backing that must be peeled off, and then they are simply placed into position. With thermal paste, the application must be precise to ensure the area is fully covered and to avoid smearing the paste where it is not needed.

Finally, the durability and longevity of the solution must be considered. Due to the materials used in thermal pads, their lifespan is finite. The