II. Thermal Pads: Fundamentals and Limitations

A thermal pad is a pre-formed, solid-state thermal interface material, typically made from a silicone base filled with thermally conductive fillers. It's designed to bridge the gap between a heat source and a heatsink, protecting devices from overheating by effectively conducting heat away.

A. Definition, Function, and Composition

The core function of thermal pads is to act as a bridge for heat transfer, conducting heat from components like CPUs and GPUs to heatsinks or device casings. They achieve this by filling the imperceptible microscopic gaps and uneven surfaces between two contacting components, thereby reducing thermal resistance and improving cooling efficiency. Common materials for thermal pads include silicone-based and graphite-based options.

B. Advantages of Thermal Pads

The primary advantages of thermal pads lie in their ease of use and suitability for mass production. They are often pre-cut to specific sizes and thicknesses, making installation straightforward without the complex application process required for thermal paste. This makes them ideal for large-scale manufacturing and assembly lines. Additionally, silicone thermal pads offer good electrical insulation.

C. Limitations of Thermal Pads

Despite their convenience, the limitations of thermal pads become apparent in scenarios demanding extreme cooling performance:

- Lower Conformability: Compared to thermal grease or thermal putty, thermal pads have limited ability to deform and perfectly fill microscopic irregularities and air gaps, potentially leading to suboptimal contact and reduced heat transfer.

- Relatively Higher Thermal Resistance: Due to conformability issues and the inherent thermal conductivity limits of the material itself, thermal pads often exhibit higher thermal resistance than some liquid or semi-solid TIMs. This can be a bottleneck for high-power components requiring maximum heat dissipation.

- Thickness Selection and Compression Issues: Choosing the correct thickness for a thermal pad is crucial. An overly thick pad increases thermal resistance, while a pad that's too thin may not adequately fill the gap. Furthermore, if the pad material lacks sufficient compressibility, it might not fully compress under pressure to form a consistent thermal layer, leading to uneven cooling or localized hotspots.

- Potential for Long-Term Degradation: Some thermal pads, particularly lower-quality ones, may harden, crack, or experience "pump-out" (where the material is squeezed out from between the interface) over time or after repeated thermal cycling, leading to a decline in thermal performance.

These limitations drive the industry to continuously explore alternative TIM solutions with better performance and wider applicability.

III. Exploring "Upgraded" Alternatives to Thermal Pads

To address the shortcomings of traditional thermal pads, various superior alternative Thermal Interface Materials (TIMs) have emerged. These alternatives offer distinct advantages in thermal conductivity, conformability, and durability, catering to the demanding requirements of diverse applications.

A. Thermal Grease / Paste

- Working Principle & Composition: Thermal grease, also known as thermal paste or compound, is a viscous fluid typically composed of a silicone or non-silicone base mixed with thermally conductive fillers like metal oxides (e.g., zinc oxide), ceramic particles, or carbon-based materials (e.g., graphite powder, diamond powder). Its primary role is to fill the microscopic air gaps and imperfections on the surfaces of the heat-generating component and the heatsink, as air is a poor conductor of heat.

- Core Advantages:

- Excellent Conformability & Extremely Low Thermal Resistance: Thermal grease wets contact surfaces exceptionally well, filling the tiniest crevices to form a very thin bond line, thereby achieving very low thermal resistance and efficient heat transfer.

- High Thermal Conductivity: Many high-performance thermal greases offer thermal conductivity values significantly higher than standard thermal pads.

- Cost-Effectiveness: For many applications, the cost per application of thermal grease is relatively low.

- Typical Applications: Widely used for CPUs, GPUs, high-performance computing modules, power modules, and other applications with stringent cooling requirements.

- Potential Drawbacks:

- Application Difficulty & Consistency: Applying thermal grease requires skill; too much or too little can negatively impact performance. Achieving consistent thickness and uniformity is challenging, making it less suitable for automated mass production.

- Overflow & Contamination Risk: Being liquid or semi-liquid, grease can squeeze out under pressure. If it contains conductive particles (like some metal-based greases), it can cause short circuits.

- Long-Term Stability Issues: Some thermal greases may suffer from "pump-out," drying, or separation over time, leading to performance degradation and requiring reapplication.

- Non-Reusable: Once a heatsink is removed, the existing thermal grease typically needs to be thoroughly cleaned and fresh grease applied.

B. Thermal Putty

- Working Principle & Composition: Thermal putty is a soft, pliable, paste-like thermal material, usually silicone-based or non-silicone-based, filled with highly conductive particles. It combines the excellent conformability of thermal grease with an ease of handling somewhat similar to thermal pads.

- Core Advantages:

- Superior Conformability & Gap-Filling Ability: Thermal putty is extremely soft and can easily fill irregular surfaces and large height differences (e.g., 0.3mm to 3.0mm), ensuring maximum contact area, outperforming traditional pads.

- High Thermal Performance: High-quality thermal putties can achieve very high thermal conductivity (e.g., Fehonda LTP81 can reach 18 W/mK).

- Suitable for Automated Dispensing: Can be applied using dispensing equipment, making it suitable for high-volume production.

- Good Durability: Compared to traditional grease, thermal putty is less prone to pump-out and maintains stable performance under thermal cycling and mechanical stress.

- Electrical Insulation: Most thermal putties offer good electrical insulation.

- Typical Applications: CPUs, GPUs (especially for VRAM and VRMs), automotive electronics, communication equipment, and any scenario with irregular surfaces or significant gaps. Fehonda LTP81 is explicitly mentioned for replacing thermal pads on graphics cards or for use when upgrading to GPU water blocks.

- Potential Drawbacks:

- Cost: Generally more expensive than traditional thermal grease and standard thermal pads.

- Cleaning & Removal: Compared to pre-formed pads, removal and cleanup might be slightly more involved.

C. Graphite Thermal Sheets/Pads

- Working Principle & Composition: Graphite thermal sheets are made from natural or synthetic graphite, leveraging the extremely high thermal conductivity of graphite's crystalline structure in specific directions (typically the X-Y plane, i.e., in-plane) to rapidly spread and transfer heat.

- Core Advantages:

- Extremely High In-Plane Thermal Conductivity: The X-Y axis thermal conductivity is exceptional, reaching hundreds or even thousands of W/mK (e.g., T68 synthetic graphite sheet up to 1500 W/mK; LST-GTM series 700−1750 W/mK), effectively spreading hotspots.

- Thin & Flexible: Graphite sheets are very thin (can be as thin as 0.01mm) and possess some flexibility, making them easy to cut and apply.

- Excellent Durability: Contains no liquid components, so it won't dry out or age, maintaining stable performance over the long term.

- Reusability: Some graphite pads can be reused if carefully removed, though other sources indicate they are not reusable as pressure can cause them to adhere to surfaces.

- Typical Applications: Heat spreading in compact electronic devices like smartphones, laptops, and tablets; CPU and GPU cooling (especially for direct contact with heatsinks where surfaces are very flat).

- Potential Drawbacks:

- Relatively Low Z-Axis (Through-Plane) Thermal Conductivity: While X-Y conductivity is excellent, Z-axis conductivity is typically only a few tens of W/mK (e.g., 10-26 W/mK). Thus, it's often better as a heat spreader than a primary gap-filling TIM, unless the gap is extremely small and surfaces are perfectly flat.

- Electrically Conductive: Graphite is an electrical conductor. Care must be taken during installation to avoid short circuits by contact with electronic components. Some products offer PET film lamination for electrical insulation.

- Not Suitable for Large Gap Filling: Graphite pads are usually thin and not designed to fill large gaps found on components like RAM and power delivery chips.

- Requires Flat Surfaces: For optimal performance, contacting surfaces need to be relatively smooth and parallel.

D. Liquid Metal TIMs

- Working Principle & Composition: Liquid metal TIMs are typically gallium-based alloys (e.g., Gallium-Indium-Tin, InGaSn) that are liquid at or slightly above room temperature. They rely on the inherently high thermal electron density of metals for superior heat conduction.

- Core Advantages:

- Extremely High Thermal Conductivity: Their thermal conductivity far exceeds all other types of TIMs, often ranging from 30−80+ W/mK.

- Extremely Low Interfacial Thermal Resistance: Liquid metal perfectly wets contact surfaces, forming a nearly gapless interface with minimal thermal resistance.

- Typical Applications: CPU cooling for extreme performance (e.g., between the die and IHS after delidding), GPU cores; high-performance computing, enthusiast overclocking.

- Potential Drawbacks:

- Electrically Conductive & Corrosive: Liquid metals are highly electrically conductive; any leakage can cause catastrophic short circuits. Gallium-based alloys are also corrosive to aluminum and cannot be used directly with aluminum heatsinks.

- Application Difficulty & Risk: Application requires extreme care to prevent spillage. Surrounding components often need insulation.

- Higher Cost: Generally more expensive than traditional thermal grease.

- Long-Term Stability & Migration Issues: Some liquid metals may migrate or be absorbed over long-term use, requiring special solutions (like the m2TIM™ approach, which uses a solid Indium preform to contain the liquid metal and prevent pump-out).

E. Phase Change Materials (PCM)

- Working Principle & Composition: Phase Change Materials transition from a solid to a softer, more flowable state at a specific temperature (typically 50−70∘C). This phase change allows them to better wet contact surfaces and fill microscopic gaps, then re-solidify upon cooling. They are usually a polymer matrix (like paraffin or copolymers) filled with highly conductive particles.

- Core Advantages:

- Combines Solid-State Ease of Use with Liquid-Like Conformability: Solid and easy to handle/pre-apply at room temperature; softens at operating temperatures to achieve grease-like surface wetting and minimal bond line thickness for low thermal resistance.

- Good Long-Term Reliability: Modern PCMs mostly soften rather than fully liquefy at operating temperatures, making them more resistant to pump-out than early-generation PCMs that truly melted, offering better long-term stability.

- No Cure Time Required: Unlike some thermal adhesives that require curing.

- Typical Applications: CPUs, GPUs, high-power semiconductors, telecom/datacom equipment, automotive electronics, and other demanding applications where long-term reliability is a concern.

- Potential Drawbacks:

- Thermal Conductivity Range: Thermal conductivity is typically in the 1−8.5 W/mK range. While better than common pads, it may not match top-tier greases or liquid metals.

- Requires Phase Change Temperature for Optimal Performance: The material must reach its phase change temperature to fully wet the interface and achieve the lowest thermal resistance.

- Thickness Limitations: Usually supplied as pre-formed thin sheets, offering less thickness flexibility than putty.

The table below summarizes the key performance characteristics of these primary TIMs:

Table 1: Thermal Interface Material (TIM) Performance Comparison Overview

| Material Type |

Typical Thermal Conductivity (W/mK) |

Conformability |

Ease of Use |

Electrical Insulation |

Durability |

Cost |

Key Advantages |

Key Disadvantages |

| Traditional Thermal Pad |

1-15 |

Moderate |

High |

Excellent |

Mod-High |

Low-Mod |

Easy to install, clean, various sizes |

Average conformability, relatively high thermal resistance |

| Thermal Grease |

1-15+ (some high-end much higher) |

Excellent |

Mod-Low |

Most good (metal-based needs care) |

Moderate |

Low-Mod |

Excellent conformability, low thermal resistance |

Messy application, potential pump-out/drying |

| Thermal Putty |

5-18+ |

Superior |

Moderate |

Excellent |

High |

Mod-High |

Perfectly fills irregular gaps, good durability, automatable |

Higher cost, slightly messy cleanup |

| Graphite Sheet |

X-Y: 100-1750+ Z: 10-26 |

Moderate (thin & flexible) |

High |

Poor (conductive) |

Very High |

Mod-High |

Exceptional planar K, thin, durable |

Average Z-axis K, conductive risk, not for large gaps |

| Liquid Metal |

30-80+ |

Superior |

Low (extreme care needed) |

None (highly conductive) |

Moderate (needs special handling for migration) |

High |

Highest K, extremely low interface resistance |

Highly conductive, corrodes Al, high application risk |

| Phase Change Material (PCM) |

1-8.5+ |

High (after phase change) |

High |

Excellent |

High |

Moderate |

High reliability, combines solid ease with liquid-like wetting |

Needs phase change temp, K not top-tier |

Choosing the right alternative requires a comprehensive assessment of the specific application's needs.

IV. How to Choose the Best Thermal Interface Material for Your Application?

Selecting the optimal Thermal Interface Material (TIM) for a specific application is not straightforward; it demands a comprehensive evaluation of multiple key factors to ensure the best balance of thermal performance, reliability, and cost-effectiveness. Here are the primary considerations when choosing a TIM:

A. Thermal Performance Requirements

- Heat Load & Target Temperature: First, determine the heat generated by the component (power dissipation) and the desired operating temperature. High-power components (e.g., high-end CPUs, GPUs, power modules) naturally require TIMs with higher thermal conductivity (W/mK) and lower thermal resistance (∘C⋅in2/W or K⋅m2/W). Higher thermal conductivity means the material transfers heat more efficiently.

- Interfacial Thermal Resistance: Beyond the TIM's bulk thermal resistance, the resistance at the interface between the TIM and the contact surfaces is critical. Materials that wet surfaces well and fill microscopic voids (like thermal grease, thermal putty, PCM after phase change, liquid metal) significantly reduce interfacial thermal resistance.

B. Gap Characteristics and Surface Conditions

- Gap Size & Uniformity: The thickness, uniformity of the gap to be filled, and surface flatness directly influence TIM selection.

- For very small and relatively flat gaps (e.g., between a CPU IHS and heatsink base), thermal grease, thin PCMs, or graphite sheets might be ideal.

- For larger or uneven gaps (e.g., between GPU VRAM/VRM components and a heatsink, or when multiple components of varying heights share one heatsink), materials with better gap-filling ability and compliance are needed, such as thermal putty or thicker, compressible thermal pads. Thermal putty is particularly suited for filling gaps with significant height variations, like 0.3mm to 3.0mm.

- Surface Roughness: Rougher surfaces require TIMs with better wetting and ability to fill microscopic cavities.

C. Electrical Property Requirements

- Electrical Insulation: In most electronic applications, the TIM must be electrically insulating to prevent short circuits between the heat-generating component and the heatsink. Silicone-based thermal pads, most thermal greases, thermal putties, and PCMs typically offer good electrical insulation.

- Conductivity Considerations: Liquid metal and graphite-based materials are electrically conductive. Strict precautions must be taken when using these materials to ensure they do not contact any live electrical parts.

D. Application Process and Manufacturability

- Manual vs. Automated: Pre-formed thermal pads and some PCMs are easy to apply manually and can also be suitable for automated placement. Manual application of thermal grease can lack consistency, but certain types of thermal grease and thermal putty can be precisely and rapidly applied using automated dispensing equipment, ideal for high-volume production.

- Rework & Maintainability: Some applications may require periodic maintenance or component replacement. Thermal pads are generally easy to remove and replace. Thermal grease needs to be thoroughly cleaned and reapplied after removal. The rework characteristics of thermal putty and PCM fall between these two. Some graphite pads claim reusability, but this should be approached with caution.

E. Long-Term Reliability and Durability

- Resistance to Pump-Out & Drying: TIMs should maintain their initial performance after long-term exposure to thermal cycling and mechanical vibration, without pump-out (material squeezing out from the interface), drying, or delamination. Thermal putty, high-quality thermal pads, and PCMs generally outperform traditional thermal grease in this regard.

- Chemical Stability & Compatibility: The TIM should be chemically compatible with the materials it contacts, without causing corrosion or degradation. For example, gallium-based liquid metal is corrosive to aluminum.

- Operating Temperature Range: The chosen TIM must maintain its performance and structural integrity across the entire operating temperature range of the application.

F. Cost Considerations

- Material Cost per Unit: The price of different types and performance grades of TIMs varies significantly. Liquid metal, high-performance graphite sheets, and some specialty putties/PCMs are generally more expensive.

- Total Cost of Application: Besides the material itself, consider the labor, equipment, and potential rework or failure costs. Automated application, while having a higher initial equipment investment, can reduce long-term labor and material waste. Choosing a highly reliable TIM, though potentially more expensive per unit, can reduce maintenance and downtime costs associated with TIM failure.

Ultimately, the selection process is a trade-off. For instance, when pursuing extreme performance regardless of cost and risk, liquid metal might be the top choice. In high-volume, cost-sensitive consumer electronics with strict electrical insulation requirements, high-performance thermal putty or optimized thermal pads could offer a more balanced solution. Understanding how these factors interact and matching them to specific application scenarios is key to successful thermal management design.

V. Fehonda: Delivering Innovative Solutions Beyond Traditional Thermal Pads

Among the many suppliers of thermal interface materials, Fehonda stands out with its comprehensive product line and commitment to technological innovation, offering the market a variety of high-performance solutions that surpass traditional thermal pads. Fehonda's products not only focus on enhancing thermal conductivity but also prioritize electrical safety, ease of use, and long-term reliability, aiming to meet a wide range of needs from consumer electronics to industrial applications.

A. Overview of Fehonda's Thermal Interface Material Product Line

Fehonda's product portfolio encompasses several advanced TIM technologies, including high-performance thermal putties, specialized thermal pads, phase change materials, and high-conductivity thermal greases. These products are optimized to address the pain points of different application scenarios, aiming to provide superior thermal performance compared to conventional silicone pads.

B. Fehonda's Star Products: Features and Advantages Explained

-

Fehonda LTP Series Thermal Putty:

- Representative Products: LTP81 (thermal conductivity up to 18 W/mK) and LTP65 (thermal conductivity 16 W/mK).

- Core Features:

- Extremely High Thermal Conductivity & Electrical Insulation: LTP81 and LTP65 provide exceptional thermal performance while maintaining excellent electrical insulation properties (breakdown voltage >10 kV/mm), making them ideal for high-performance applications with stringent safety requirements. This "safe high-performance" characteristic distinguishes them in scenarios requiring top-tier cooling without the electrical conductivity risks of liquid metal or some graphite materials.

- Superior Conformability & Gap-Filling Capability: Fehonda thermal putties are very soft, easily filling irregular gaps and height differences from 0.3mm to 3.0mm, ensuring intimate contact with heat-generating components and minimizing interfacial thermal resistance. This is particularly crucial for components of varying heights on graphics cards, such as VRAM and VRMs.

- High Reliability & Durability: These putties exhibit good high-temperature tolerance (e.g., LTP81 operating temperature range −40∘C to 180∘C), low stress, and are resistant to common issues like pump-out or drying seen in traditional greases, ensuring long-term stable thermal performance.

- Ease of Application & Customization: Despite being a putty, it has a slight tackiness for convenient pre-assembly. Importantly, Fehonda mentions that LTP81 product parameters can be customized, indicating strong B2B service capabilities to provide tailored solutions for OEM/ODM clients, in addition to retail offerings.

- Why It's an Excellent Alternative: For applications requiring the filling of large or irregular gaps, high thermal conductivity, and a focus on electrical safety and long-term reliability, the Fehonda LTP series thermal putty is an ideal upgrade from traditional thermal pads. Its performance far exceeds standard pads, and its application flexibility makes it suitable for GPU thermal modification, high-performance CPU cooling, LEDs, and various other scenarios. Reddit communities also feature user recommendations for Fehonda's thermal putty products, citing their excellent performance.

-

Fehonda High-Performance Thermal Pads:

- Representative Products: 15W/mK series and 12.8W/mK series thermal pads.

- Core Features:

- High Thermal Conductivity: Offering thermal performance significantly above common silicone pads, with models like 15 W/mK and 12.8 W/mK effectively tackling high heat flux challenges.

- Electrical Insulation & Safety: Fehonda emphasizes the non-conductive nature of its thermal pads, a claim supported by reviews from PRO Hi-Tech and Vik-Off, where their 15W pad ranked first among non-conductive thermal pads. These independent third-party reviews greatly enhance product credibility, offering a strong choice for safety-conscious consumers and businesses.

- Softness & Conformability: Some high-performance models (like the 15W series) are very soft, even compressible like thermal putty, improving upon the conformability limitations of traditional pads.

- Diverse Thickness Options & Customization: Available in a wide range of thicknesses from 0.5mm to 3.0mm and even thicker, often in 0.25mm increments, to meet the precise gap requirements of different devices. Fehonda also offers customization services for thermal pads, including color and thickness.

- Why It's an Excellent Alternative: For users who prefer pre-formed thermal pads but require performance far exceeding standard silicone pads, Fehonda's high-performance pads offer an ideal balance. They combine the ease of use and cleanliness of pads with thermal conductivity approaching high-end TIMs, all while ensuring electrical safety. They are particularly suitable for GPUs, CPUs, overclocked devices, and other situations needing pre-formed solutions.

-

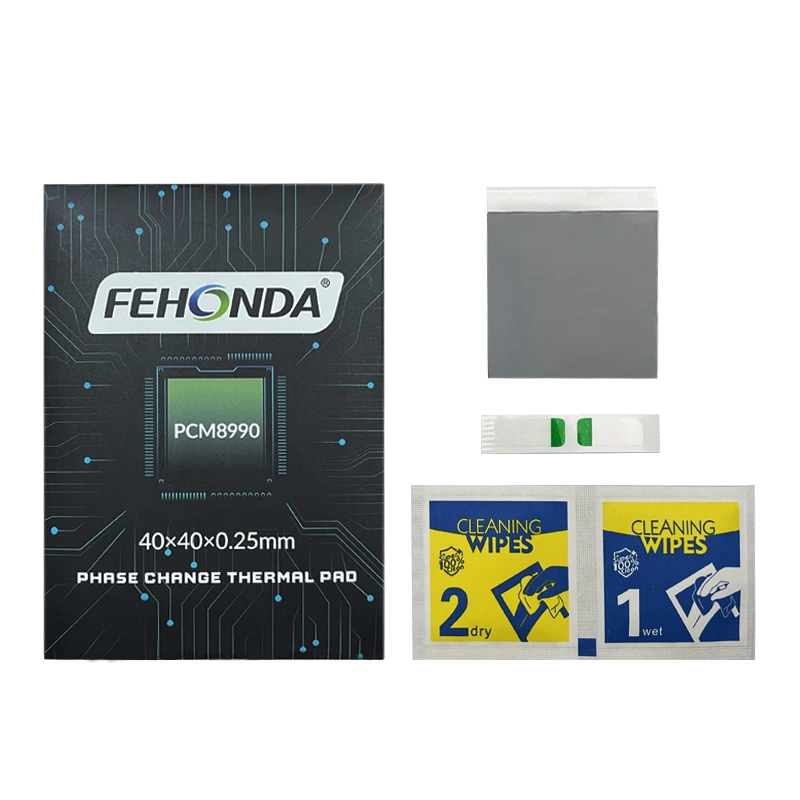

Fehonda PCM8990 Phase Change Material:

- Product: PCM8990 (thermal conductivity 8.5 W/mK, also mentioned in Fehonda's product listings).

- Core Features:

- Excellent Interface Wetting & Low Thermal Resistance: After reaching its phase change temperature (typically 50−70∘C), the material softens and wets the contact surfaces exceptionally well, forming a very thin bond line and achieving extremely low thermal resistance (<0.04∘C⋅cm2/W).

- Superior Long-Term Reliability: PCM8990 has passed rigorous reliability tests, such as 1000 hours of baking at 150∘C and 1000 cycles of T/C-B (temperature cycling B, −55∘C to +125∘C), while maintaining low thermal resistance. This makes it especially suitable for devices requiring long-term stable operation and experiencing significant temperature fluctuations.

- Thin Profile Design: Available in thin specifications like 0.2mm/0.25mm, suitable for flat packages with strict thickness requirements.

- Why It's an Excellent Alternative: For high-performance integrated circuits, devices with long-life requirements, and applications frequently undergoing temperature changes, Fehonda PCM8990 provides a more reliable thermal interface solution than traditional grease or common pads. It combines the handling ease of solid materials with the excellent conformability of liquid materials at operating temperatures.

-

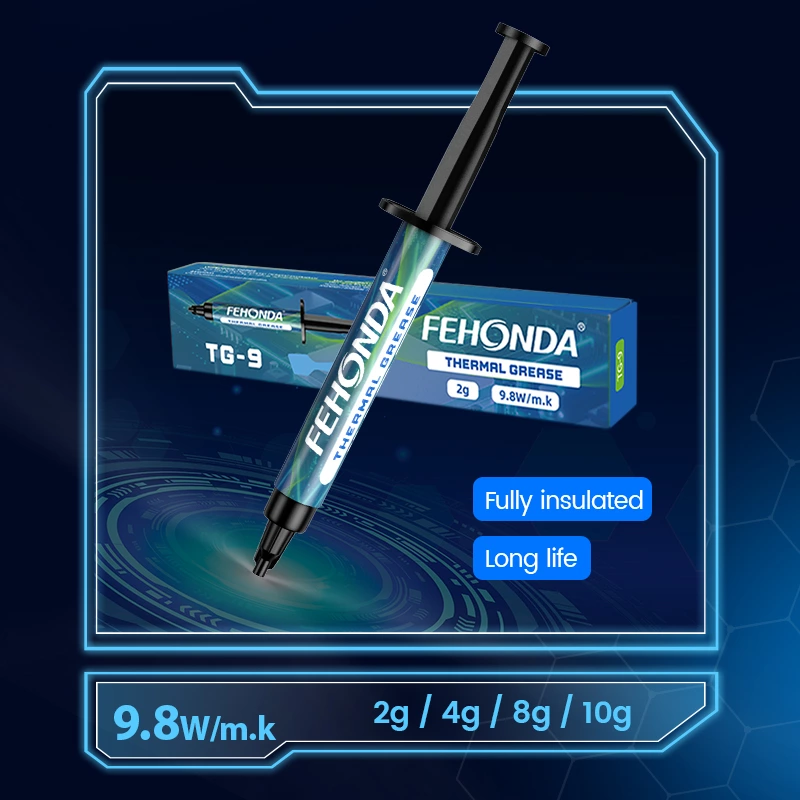

Fehonda Thermal Pastes:

- Representative Products: TR50L (thermal conductivity 14.8 W/mK) and TG-8 (thermal conductivity 8.5 W/mK).

- Core Features:

- TR50L Enthusiast-Grade Performance: Designed for enthusiasts, featuring low thermal resistance, an included applicator for easy and even spreading, and long-term stability, resisting drying and cracking.

- TG-8 General Purpose & Automation Adaptability: Non-corrosive, chemically stable, good electrical properties, and suitable for automated dispensing equipment, meeting high-volume production needs.

- Why It's an Excellent Alternative: For users who still prefer traditional thermal paste, Fehonda offers high-performance options. TR50 caters to the extreme cooling demands of overclockers and high-end DIY users, while TG-8 balances performance with convenience and reliability for industrial applications.

The following table summarizes Fehonda's key alternatives to thermal pads and their critical features:

Table 2: Overview of Fehonda's Key Thermal Pad Alternative Solutions

| Fehonda Product Model |

Type |

Thermal Conductivity (W/mK) |

Key Features & Advantages |

Recommended Applications |

| LTP81 |

Thermal Putty |

18 |

Very high K, non-conductive, excellent conformability (0.3-3.0mm gaps), durable, UL certified |

GPU (VRAM/VRM), CPU, LED, complex component cooling |

| LTP65 |

Thermal Putty |

16 |

High K, non-conductive, excellent conformability, durable |

GPU, CPU, high-performance devices |

| 15W Thermal Pad |

Silicone Pad |

15 |

High K, non-conductive, soft, various thicknesses, #1 non-conductive in PRO Hi-Tech/Vik-Off reviews |

GPU, CPU, overclocking devices, pre-formed needs |

| 12.8W Thermal Pad |

Silicone Pad |

12.8 |

Good K, non-conductive, various thicknesses, reviewed by PRO Hi-Tech/Vik-Off |

GPU, CPU, motherboards, chipsets |

| PCM8990 |

Phase Change Material (PCM) |

8.5 |

High reliability, low thermal impedance, thin (0.2mm), excellent wetting |

High-perf. ICs, long-life devices |

| TR50L |

Thermal Paste |

14.8 |

Enthusiast grade, low impedance, easy application tool, long-life stability |

CPU, GPU (high-performance, overclocking) |

| TG-8 |

Thermal Paste |

8.5 |

Non-corrosive, good electricals, stable, automation-friendly |

General CPU/GPU, power modules |

C. Fehonda's Quality Commitment and Certifications

Fehonda maintains strict control over its product quality. Many of its thermal interface materials, including LTP81 thermal putty, TG-8 thermal grease, various thermal pad series, and PCM8990 phase change material, are listed or mentioned as having passed multiple international certifications such as ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), ISO 45001 (Occupational Health and Safety Management System), RoHS (Restriction of Hazardous Substances), UL (especially UL 94 V-0 for flame retardancy), and CE. The company itself is described as a national high-tech enterprise with independent R&D and production facilities, as well as comprehensive quality control equipment. These certifications and corporate credentials not only guarantee product safety and compliance but also reflect Fehonda's commitment to quality and environmental protection, providing confidence to customers, especially B2B clients and consumers with high quality expectations.

D. Customer Reviews and Industry Recognition

Beyond its internal quality assurances, Fehonda's products have also received positive feedback from third-party reviewers and users. Its thermal pad products have garnered attention and testing from YouTube tech review channels PRO Hi-Tech and Vik-Off, performing notably well in the non-conductive thermal pad category. Furthermore, on tech forums like Reddit, users have shared positive experiences using Fehonda thermal putty (like LTP81) and achieving good cooling results. User feedback on e-commerce platforms like AliExpress is also generally positive, affirming product performance and ease of use. This external positive feedback and recognition provide strong evidence of Fehonda's products' real-world performance, enhancing their market competitiveness.

Fehonda has established its professional standing in the thermal interface material field by offering diverse, high-performance, and safety-focused thermal solutions, complemented by strict quality control and customer customization capabilities. For users seeking upgraded alternatives to traditional thermal pads, Fehonda is undoubtedly a brand worth serious consideration.

VI. Conclusion: Choosing the Right "Cooling Companion" for Your Device

The choice of Thermal Interface Material (TIM) is far more complex than it may seem, directly impacting the performance, operational stability, and overall lifespan of electronic devices. While traditional thermal pads are convenient, their performance bottlenecks become increasingly apparent when faced with escalating cooling challenges. Through this in-depth discussion, we've explored various alternatives such as thermal grease, thermal putty, graphite thermal sheets, liquid metal, and phase change materials. Each offers superior cooling possibilities for different scenarios, leveraging unique physical properties and application advantages.

A. Recap of TIM Diversity and Importance

Revisiting the article, the world of thermal interface materials is diverse, extending far beyond standard silicone pads. Each TIM has its specific working principle, advantages, and limitations. Recognizing this diversity and understanding the critical importance of selecting the right TIM for optimizing thermal management, preventing component overheating, and ensuring device reliability is an indispensable part of modern electronic design and maintenance.

B. Application Needs are the Ultimate Deciding Factor

It must be emphasized that there is no "one-size-fits-all" best alternative to thermal pads. The most suitable choice always depends on the specific application requirements. Designers or users must carefully weigh the factors discussed in Section IV: the component's heat load, target operating temperature, gap geometry (size, flatness, uniformity), electrical insulation requirements, application process convenience and cost, and expectations for long-term durability. Optimal cooling effects and overall benefits can only be achieved when the TIM's characteristics are highly matched with the application's specific demands.

C. Fehonda: Your Trusted Expert in Thermal Solutions

When seeking high-performance thermal solutions, Fehonda demonstrates its strength and commitment as a professional supplier. With its comprehensive product line—including high-performance thermal putties (like LTP81, LTP65), advanced thermal pads (like the 15W/mK, 12.8W/mK series), high-reliability phase change materials (like PCM8990), and enthusiast-grade thermal greases (like TR50L)—Fehonda offers a diverse range of options for various complex and demanding cooling challenges. Its products not only pursue exceptional thermal performance but also emphasize electrical safety, long-term stability, and ease of application, backed by multiple international certifications and earning industry and user recognition.

D. Call to Action

Choosing Fehonda means selecting a professional partner in the field of thermal management to jointly address cooling challenges and ensure your devices operate at their best. With scientific selection and high-quality products, your equipment will gain lasting, cool power.