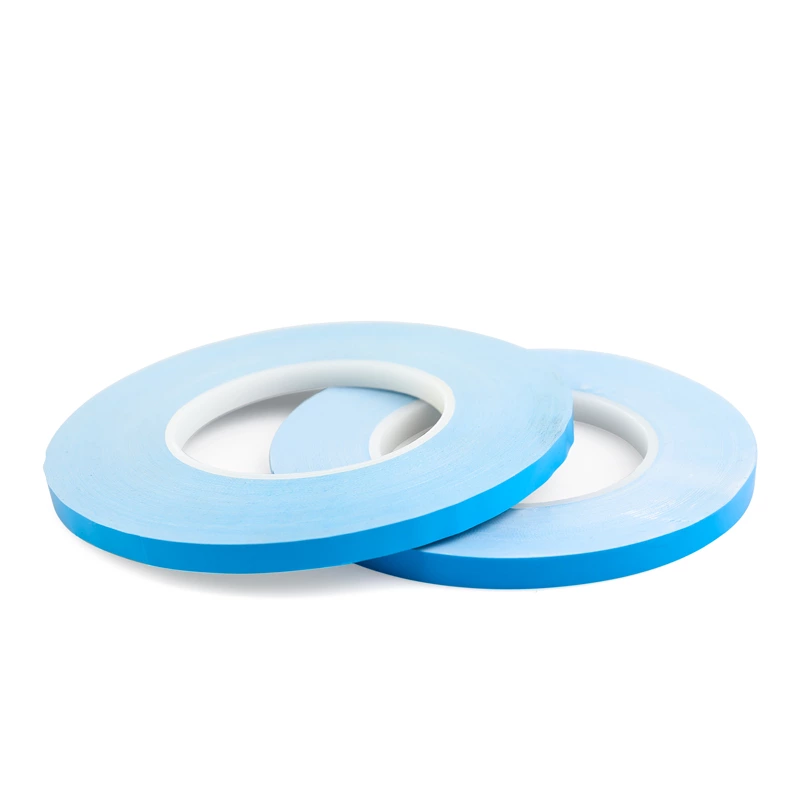

Thermal TA 1200 Tape

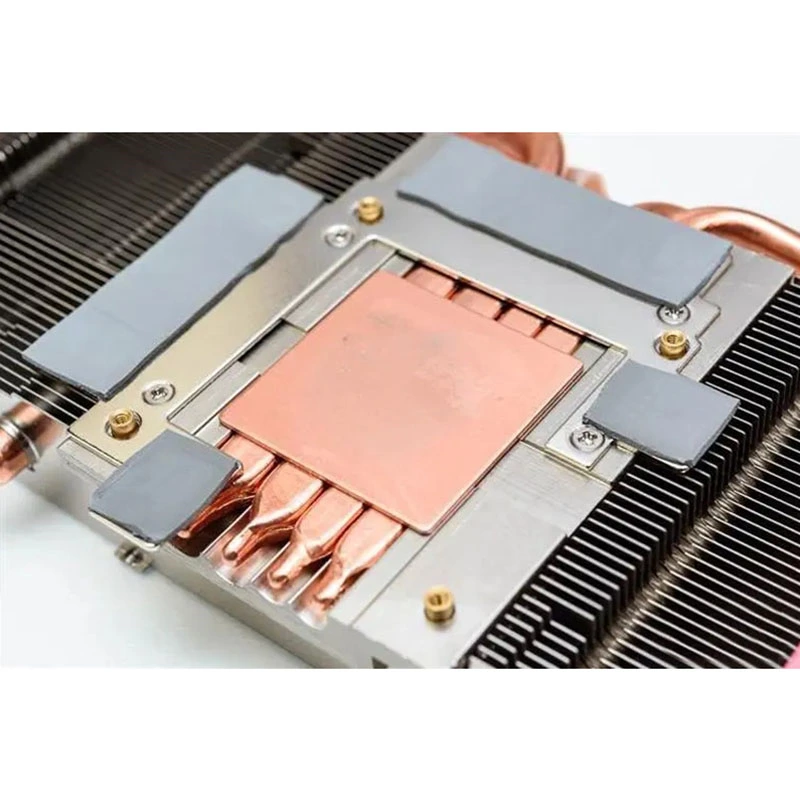

Thermal TA 1200 is a thermally conductive double-sided adhesive tape made from a high-performance acrylic pressure-sensitive adhesive filled with highly thermally conductive ceramic particles, which is coated on both sides of a thermally conductive polyimide film. This thermally conductive double-sided tape provides an efficient heat conduction channel between electronic devices and heat sinks, eliminating the need for mechanical fixation or liquid adhesive curing and fixation between them. It features high thermal conductivity and insulation properties, along with softness, compressibility, conformability, and strong adhesion. It adapts to a wide temperature range, can fill uneven surfaces, and can tightly and firmly adhere to heat source devices and heat sinks, rapidly transferring heat away

Typical Applications

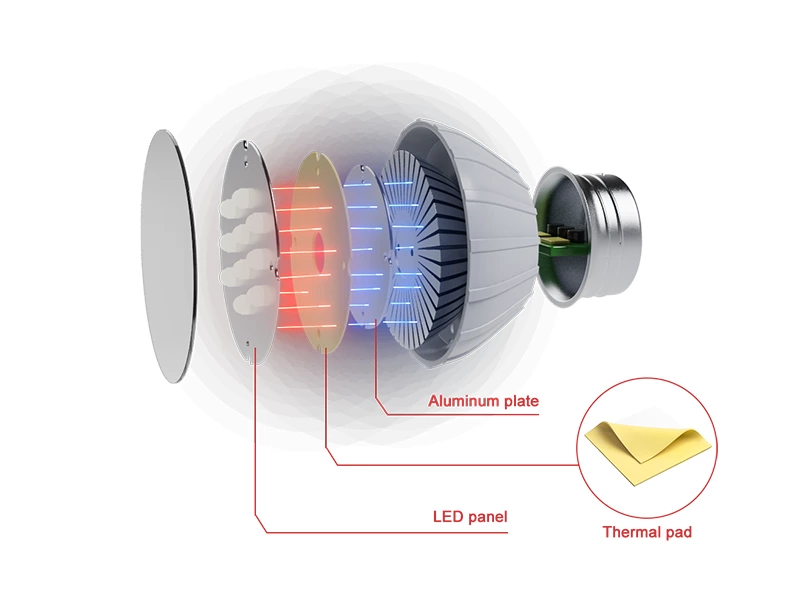

- Adhesive heat conduction between LED lighting fixtures and heat sinks.

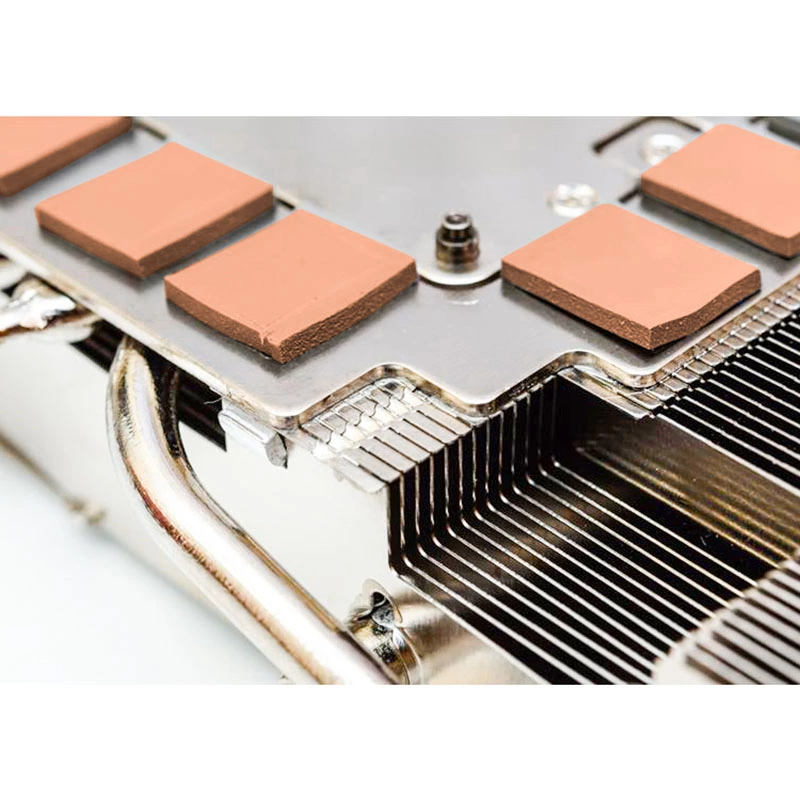

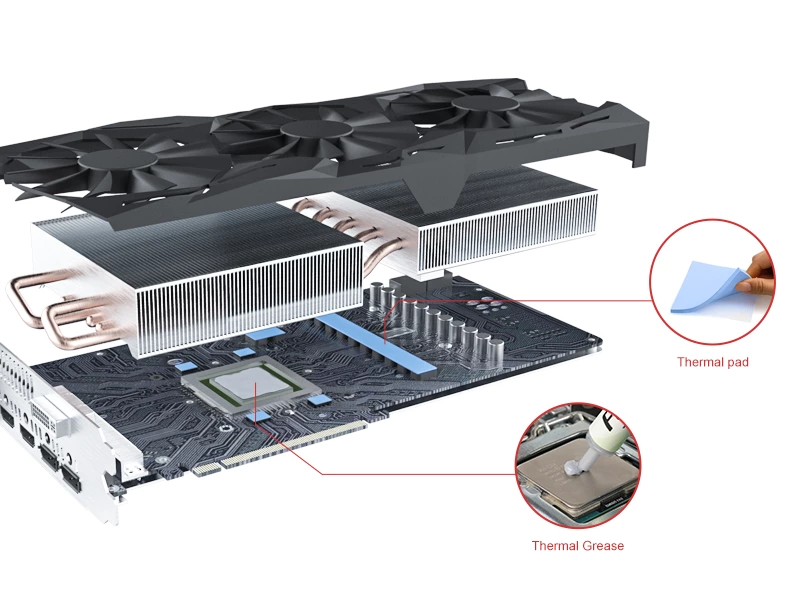

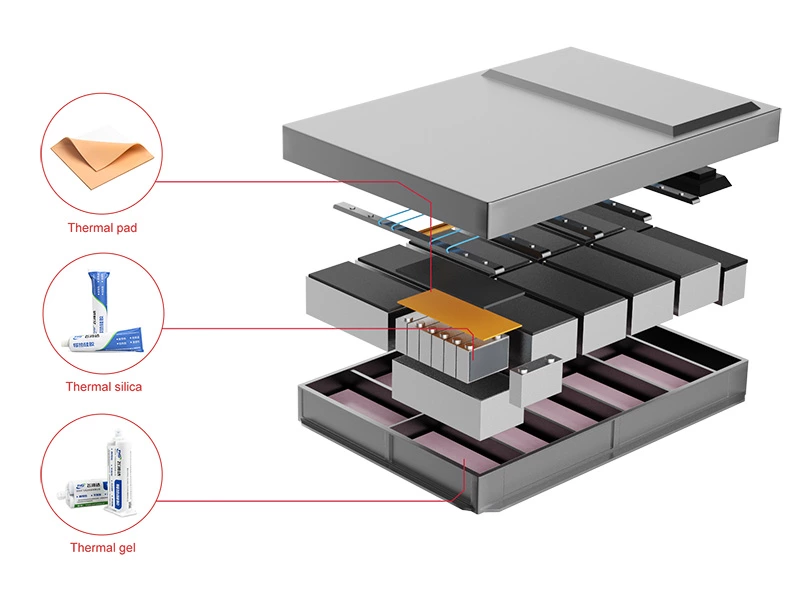

- Adhesive heat conduction for chips and heat sinks.

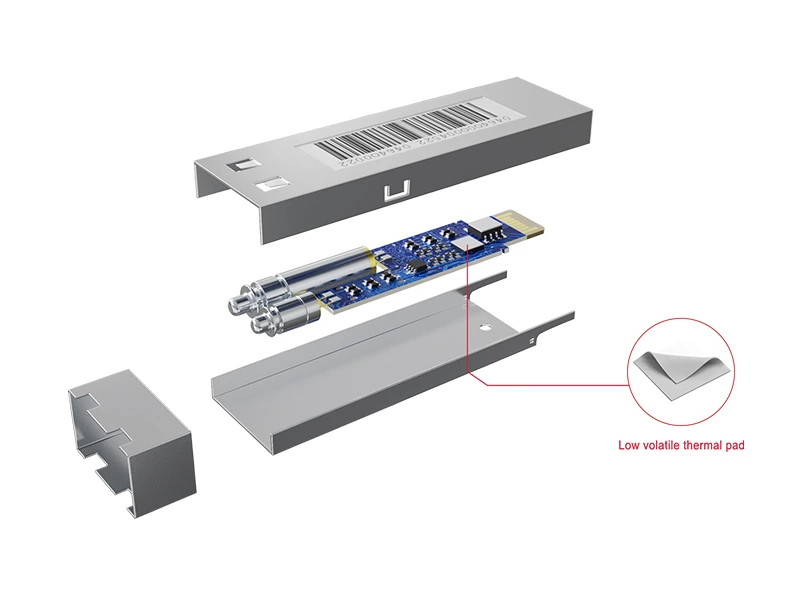

- Adhesive for flexible circuits and high-power crystal components or other cooling devices.

- Applicable to LED lighting, communication equipment, consumer electronics, artificial intelligence, optical instruments, etc.

Features and Advantages

Good thermal conductivity, low thermal resistance

Adhesive strength increases with time and temperature rise

Good insulation performance and temperature resistance

Soft, compressible, conformable, high reliability in use

Flame retardant rating UL94V-0, meets ROHS environmental protection requirements

Thermally conductive double-sided tape supports die-cutting of any shape product for customers

| Test Item | Unit | Technical Indicator | Test Standard |

| Color | / | Light Yellow | Visual |

| Thickness | mm | 0.2 | ASTM D374 |

| Substrate | / | Thermally Conductive Polyimide | / |

| Temperature Resistance Range | °C | -40~+130 | / |

| Breakdown Voltage | KVAC | 6.5 | ASTM D149 |

| Volume Resistivity | Ω.cm | ≥1×1014 | ASTM D257 |

| Flame Rating | / | V-0 | UL 94 |

| Thermal Conductivity | W/mK | 1.2 | ASTM D5470 |

| Adhesive Strength | N/cm | 7.2 | ASTM D1002 |

Usage and Storage Instructions

Customization

- Available Specifications

- Sheet material, roll material, die-cut shapes (can be die-cut into various sizes and shapes according to customer specifications).

- Thickness

- Standard thickness: 0.2mm.

Storage

- Storage life: 24 months;

- Storage conditions: Store at room temperature, protected from dust, in a cool and dry place indoors.

Transportation

- This product is non-hazardous and can be transported as a general chemical product.

Operation

- Customers should select products of appropriate thickness and width based on the actual situation to achieve the best results. The surface of the components should be kept clean, free of oil and impurities. When using, stick to the surface of the heating element first, then remove the release liner, and then attach the other side to the heat sink. Apply a certain pressure to ensure tight adhesion, achieving the best adhesion and heat conduction effect.